-

Improve Fragmentation Flow and Ore Recovery

Whichever our customers' needs are, be it improved fragmentation, reduced dilution, expanded patterns or reduced oversize; we have the solution. As part of our Hypercharge™ Performance service, we will work with you to deliver on your needs and priorities such as preconditioning blasting, ore to specifiion, dilution control and mass blasting.

Get Price -

ore mining blast materials

Blasthole drilling and grade control sampling at the DM45 drill rig. ... ORE TRACKING: Mining equipment implemented for ore extraction is optimal for selective mining. Material from the pit is transported to various stockpile destinations. These include highgrade (>13% Zn), mediumgrade (9 13% Zn), lowgrade (4 9% Zn) and marginal (1 ...

Get Price -

Our Iron Ore Product

Surveying of land confirms whether iron ore is present. If so, blast team preps area for mining. Iron Ore Is Crushed. Large raw material is crushed into smaller material to be processed in the mill. Drying Process. ... Surveying of land confirms whether iron ore is present. If so, blast team preps area for mining. Heavy Equipment Operation.

Get Price -

History and heritage: Novel gold ore treatment at the Wiluna .

· The Moonlight ore contained the antimony mineral, stibnite, which was notoriously difficult to roast and cyanide, and a pilot plant was built to investigate the smelting of Moonlight concentrates by sintering, blast furnace smelting with lead and lead concentrates, and refining to obtain the gold.

Get Price -

Making steel | ArcelorMittal

Making steel. Steel is made from iron ore, a compound of iron, oxygen and other minerals that occurs in nature. The raw materials for steelmaking are mined and then transformed into steel using two different processes: the blast furnace/basic oxygen furnace route, and the electric arc furnace route. Both processes are being continually improved ...

Get Price -

OpenPit Mining Methods

· The gloryhole method has been used extensively for mining relatively small pipe or wedgeshaped ore bodies or the upper parts of bodies that apex at or near the surface, and for mining the ore remaining in track benches and in the bottom of powershovel pits below the elevation where locomotive haulage becomes uneconomical because of adverse t...

Get Price -

Iron ore | BHP

The ships we use to transport iron ore to our customers can carry around 47 Olympicsized swimming pools worth of material. Fe. ... in a blast furnace. Heating. Air that has been heated to around 1,200°C is injected into the furnace, converting the iron ore to molten pig iron and slag. ... The ramp up of the US billion South Flank iron ore ...

Get Price -

Wasol Mining | Wasol Mining SA Group

Wasol Mining SA Group is a mining company in South Africa that does all the mining of Iron Ore, Borates, ... We produce materials essential for human progress. Iron Ore. Today, ... used in steelworks as sinter plant feed or direct blast furnace feed. Learn More. Aluminum. We are a global leader in aluminium, with a largescale, ...

Get Price -

Shaft Mining, Mining Techniques, Underground Mining, Mining .

Shaft mining is a form of underground mining where shafts are pushed vertically from top to bottom to excavate the ores and minerals. It is also called shaft sinking. It is best suited for concentrated minerals such as iron, coal, etc. which can be found at the depth of the earth's surface. It is found mostly all over the world.

Get Price -

Loading and Haulage Equipment Selection for Optimum .

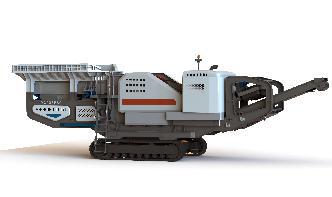

Mining trucks, also referred to as haul trucks or road trucks, are used to haul (transport) the ore or waste material from the loader to the dumpsite. In most cases, these vary from 36 tons to 315 tons. The size and cost of operating mining trucks are .

Get Price -

Vermeer says continuous surface mining and drill blast can .

· Overburden is any material above the desired ore product, such as a waste seam above different levels of a pit. "For mines that have a significant amount of overburden, it might be faster and more costeffective to blast the overburden and then use continuous surface mining for precision mineral, ore or aggregate extraction," explained ...

Get Price -

Bulking/Swell of Excavated or Mined Materials

The same excavation in feet: Excavated area is 200 feet long 20 feet wide and 2 feet deep with a listed swell of 40% for the material. Bank volume = 200 * 20 * 2 = 8000 ft³. Convert 8000 ft³ to yd³ = 8000/27 = 296 yd³. Loose volume = 296 * = 414 yd³. (Calculations are based on the material being of similar consistency.

Get Price -

Platinum Mining and Refining | Eduion

Most of the mining for platinum ore occurs deep underground. To extract the mineralrich materials, miners pack explosives into holes drilled in the rock and blast it into smaller pieces. The broken rock is then collected and transported to the surface for processing. Platinum production in South Africa. Photo by Johnson Matthey.

Get Price -

Blasted ore

Blasted ore. It needs washing before it disintegrates. Blasted ore is obtained after detonating a hard rock face in the blast mine. Players must first excavate the hard rock using a chisel, then using a pot of dynamite on the resulting cavity. Then, players must light the dynamite and run away from it, or large amounts of damage will be taken.

Get Price -

Transparency on greenhouse gas emissions from mining to enable ...

· These technologies are focused on emissions reduction through reduction of coking coal and include: blast furnaces with top gas recycling, smelting reduction (HIsarna), direct reduced iron and iron...

Get Price -

Fracture characteristics of iron ore under uncoupled blast loading

Apr 08, 2022 · 1. Introduction. Iron ore, a raw material used in steel manufacturing, is typically mined by blasting. The energy utilization rate of explosives can be increased, and the energy consumption rate of blasting equipment decreased, by adopting a rational decoupled charge approach,,, .During mining, the lumpiness of the iron ore should be neither too large nor too .

Get Price -

Formation and removal of hangups in ore passes: Mining .

· When material is too fine, cohesive arches can form. Methods of removing hangups include the use of explosives or water. Explosives can be used to bomb the surface of the hangups, be inserted into the hangups or inserted through bore holes drilled to the hangups from the surrounding excavations. Water can be poured from above, jetted from ...

Get Price -

Pellet, iron ore concentrste, sintered iron ore: buy from Metinvest ...

Iron ore pellets are produced from the iron ore concentrate by pelletizing and sintering and are used as the feedstock for the blast furnace process. Metinvest offers a range of iron ore pellets for the blast furnace process, such as nonfluxed pellets produced by Central GOK with a basicity of and % iron content, nonfluxed pellets ...

Get Price -

Valheim ore guide: How to find, smelt, and craft all metals

· Instead, you'll need a Blast Furnace, which is essentially a level two Smelter. You can make it with 20x Stone, 5x Surtling Cores, 40x Iron, and 40x Fine Wood. Valheim ore guide: How to craft bronze

Get Price -

The value of mineralogical analysis for iron ore mining and ...

· This "Mineralogy in Mining" blog series started with a general overview of the value of mineralogical monitoring for an efficient ore the last decades highgrade iron ore deposits, particularly in Western Australia, required hardly any downstream processing. Iron ores were simply crushed and shipped as lump ore for iron making.

Get Price -

Analysis of iron ore pellets properties concerning raw material ...

· 1. Introduction. The demand and supply of iron ore and steel production are allied to each other. According to the new National Steel Policy 2017, the Ministry of Steel, Govt. of India has set up a target to produce 300 million tonnes per annum (MTPA) of crude steel making by 2030–31 [].For the production of 300 MTPA, around 450 MTPA of highquality iron ore is .

Get Price -

Ore – Minecraft Wiki

Ores can be smelted faster using a blast furnace.. It is not efficient to mine with Silk Touch and then smelt an ore block that normally drops multiple pieces of its resource, because smelting these ores yields less experience and only 1 piece of the resource. Nether gold ore is the only exception, as each ore block drops an average of gold nuggets even when mined with .

Get Price -

Iron Ore Pelletizing Process: An Overview

· In the blast furnace, iron is reduced and melted and the most common product is liquid iron called hot metal. In direct reduction, iron remains in solid state and the product is the socalled direct reduced iron (DRI). Generically, the iron ore products for ironmaking can be classified as shown in Table 1. Table 1.

Get Price -

Iron Ore Mining Blast Frurnace For Sale

Indian Bureau of Mines. Lumpy iron ore (3010 mm) and agglomerates like sinter pellets form the feed for the production of pig iron in blast furnace, whereas steel scrap, lumpy iron ore (186 mm) or pellets are the feed for sponge iron production. The blast Iron ore specifiion required by major Integrated Steel Plants. Iron Ore Blast Holes

Get Price