-

What is Cement Clinker? Composition, Types Uses

Clinker is a nodular material produced in the kilning stage during the production of cement and is used as the binder in many cement products. The lumps or nodules of clinker are usually of diameter 325 mm and dark grey in color. It is produced by heating limestone and clay to the point of liquefaction at about 1400°C1500°C in the rotary kiln.

Get Price -

Gypsum

Home > Gypsum. Gypsum. TO BE COMPLETED ! Our expertise. We design, ... Ball Mill process. OBJECTIVE This case study is based on a real field trial to produce cement with lower carbon footprint optimazing clinker factor and SCM content. The 2 .

Get Price -

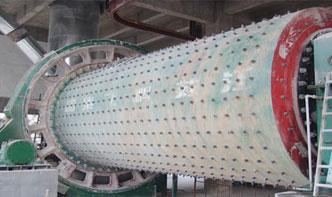

Selenite Ball Mill

The ball mill is mainly a machine for dry or wet grinding of the crushed gypsum. The machine is mainly used for repeated grinding of the raw materials in the barrel through the steel ball medium in the ball mill to complete the ball grinding operation. Advantages of Fote ball mill. The ball mill can control the grinding time flexibly and reduce

Get Price -

Clinker And Gypsum Grinding Mills

· Clinker Grind With Gypsum Cementtischler Dec 20 2016 Clinker and gypsum being mixed together in predetermined proportions are fed to the grinding mills Chemical gypsum if used instead of natural gypsum needs to be dried either by natural sun drying or by mechanical drying before it is used with cooled and dried clinker for inter grinding .

Get Price -

hammer mill for processing gypsum 1

concrete crusher and metal separators how can i machine feldspar or quartz mine local gold elution machine zimbabwe por le gold mining crusher for sale cost of ...

Get Price -

RETSCH – Laboratory Mills, Crushers and Sieve Shakers

Laboratory Mills, Crushers and Sieve Shakers. RETSCH is the leading solution provider for neutraltoanalysis sample preparation and characterization of solids. Based on a century of experience RETSCH develops size reduction and sieving equipment which is characterized by excellent performance, operating convenience, safety and a long lifetime.

Get Price -

Ball Mill

RETSCH is the world leading manufacturer of laboratory ball mills and offers the perfect product for each appliion. The High Energy Ball Mill E max and MM 500 were developed for grinding with the highest energy input. The innovative design of both, the mills and the grinding jars, allows for continuous grinding down to the nano range in the shortest amount of time with .

Get Price -

Welcome To Claudius Peters | Claudius Peters

Claudius Peters stockyards, pneumatic conveyors, silos, clinker coolers, grinding mills, and packing systems can be found in Cement, Coal, Alumina, and Gypsum plants across the globe. The group's other principal Division, Aerospace, manufactures aircraft parts for Airbus. Sectors Alumina Aluminium Cement Gypsum Iron Steel Marine

Get Price -

clinker and gypsum going in ball mill

how does the clinker grinding unit work Feb 13, 2019 how does a grinding cement mill work YouTube. Aug 25, 2016 Diamond grinding is a concrete pavement restoration technique that corrects irregularities such as faulting and roughness on concrete pavements. cement ball mill design pdf, India Ball Mill Cost for 100 ton Cement Production Plant,Used Robo Sand Project .

Get Price -

Steel Ball – Raiva International Trading

Steel ball production process: Casting of chromeplated steel ingots with square sections with sides 160,140, 180 mm Rolling ingots into bars with a diameter of 25 to 100 mm Heating the wire inside the heat treatment furnace Rolling and forging balls with a diameter of 25 to 100 mm Perform heat treatment Ball quality control final product

Get Price -

Professional Ore, Cement Clinker, Gypsum, Ceramic Mining Grinding Ball Mill

Model NO.: 900*3000 Motor Type: AC Motor Type: Ball Mill Condition: New Model Number: 1830*7000 Power: 245kw

Get Price -

Mixing The Clinker With Gypsum And Grinding

Clinker and gypsum being mixed together in predetermined proportions are fed to the grinding mills. Chemical gypsum if used instead of natural gypsum needs to be dried either by natural sun drying or by mechanical drying before it is used with cooled and dried clinker for inter grinding in mills. Live Chat; CLINKER GRINDING IN CEMENT ...

Get Price -

Gypsum

Gypsum TO BE COMPLETED ! Our expertise We design, produce, market and deliver our own systems and solutions for concrete producers and users all over the world. High performance and durable construction Tailor made solutions with local resources Solutions for challenging Jobsites Challenging sand use and local materials Cost optimization

Get Price -

en/wet ball mill minerals at main · sbmboy/en

. Contribute to sbmboy/en development by creating an account on GitHub.

Get Price -

Clinker company list in China

cement, clinker Qingdao Kylin Impex Limited Rm 1702, Land of Wealth, Yan'an San Rd, Qingdao, China We are a company established in 2004 by group of experienced professionals from Cement Department the former Shandong Provincial Minmetals, governmentleading .

Get Price -

The Incorporation of Steel Slag into BeliteSulfoaluminate Cement Clinkers

· The potential use of steel slag from treated steel slag in belitesulfoaluminate cements was investigated in this study. Cement clinkers with two phase compositions were synthesized, allowing the incorporation of different amounts of steel slag. The phase composition and microstructure of cement clinkers at three different sintering temperatures were studied .

Get Price -

Bond Work Index Tables (Wi) | PDF | Rock (Geology) | Minerals

Tsakalakis G. Konstantinos Description: Here there are given tables from various sources for the Bond work index values of mining materials (ores, industrial minerals and rocks). These work indexes can be used for the determination of tumbling mills (rod, ball mills) power. Thus, the suitable mill dimensions can be effectively determined.

Get Price -

Clinker And Gypsum Ball Mill

Working Of Ball Mill With Gypsum And Clinker. Jul 16, 2015 Method for grinding of material, especially raw material for clinker calcination, in mills, particularly in ball mills (22) (43) (57) A method of grinding material, in particular a raw material mixture for firing clinker in mills, in particular ball mills, in a tubular ball mill.

Get Price -

types for ball mill with gypsum and clinker

suitable assumptions for gypsum and clinker in ball mill. CEMENT MILLS Two chamber ball mills for the cement industry 95 clinker 5 gypsum 95 cement mills with enclosed girth gear This type of drive features grinding circuits for grinding clinker replacement materials Composition of mill feed Clinker Gypsum System Ball mill Roller mill OK 36 4 Clinker 78 75suitable .

Get Price -

8000M Mixer/Mill ® HighEnergy Ball Mill

8000M Mixer/Mill ® HighEnergy Ball Mill The 8000M Mixer/Mill is a highenergy ball mill that grinds up to 10 grams of dry, brittle samples. The vial, which contains a sample and one or more balls, is shaken in a complex motion that combines backandforth swings with short lateral movements, each end of the vial describing a figure8.

Get Price -

working of ball mill wi th gypsum and clinker

Gypsum Conical Ball Mill . Clinker And Gypsum Mixing In Vertical Mill Crusher Mills. working of ball mill with gypsum and clinker A lot of people are talking about working of ball mill with gypsum and clinker 2011 Vertical roller mill used in the cement mixing plant i Making. Read more. Inquire Now; working of ball mill with gypsum and ...

Get Price