-

Future Grinding Technologies

Each single entry was equipped with specific data about quality aspects, flexibility aspects regarding feed, operation behaviour, maintenance aspects, efficiency aspects and environmental impacts. ... This grinding system consists of a highly efficient fine crushing unit, a conventional grinding unit for a medium fineness, and a fine grinding ...

Get Price -

International Conference on Minerals Processing, Crushing and Grinding ...

12/07/2022 · Minerals Processing, Crushing and Grinding scheduled on July 1213, 2022 in July 2022 in Stockholm is for the researchers, scientists, scholars, engineers, academic, scientific and university practitioners to present research activities that might want to attend events, meetings, seminars, congresses, workshops, summit, and symposiums.

Get Price -

The difference between crushing and grinding

24/05/2021 · The purpose of material crushing (grinding) Increase the specific surface area of the material After the material is broken, its specific surface area increases, which can increase the effect of physical action and the speed of chemical reaction. For example, the mixing of several different solid materials, if the object is finely broken, the ...

Get Price -

fundamental aspects of crushing

fundamental aspects of crushing fundamental aspects of crushing Accounts of Crushing from the Heart of Baviera May 11, 2017 · The use of the crusher bucket also allowed the construction company to completely recover the materials present onsite, with an evident reduction in emissions and consumption and a general reduction in noise pollution .

Get Price -

Stone crusher plant design | Henan Deya Machinery Co., Ltd.

19/04/2022 · In the stone crusher plant processing, the appropriate stone crusher should be chosen based on the different raw materials. First of all, when we egorize the raw materials, we can roughly divide the raw materials into hard stone and soft stone. Hard stone typically includes cobblestone, granite, basalt, whose hardness is basically above 150Mpa.

Get Price -

Options for Grinding Slag and Pozzolan for Use as Construction ...

Grinding aids in a ball mill can proficiently impact production cost. 4 Three major aspects in grinding aid would be decrease "packset," increase flowability and reduce moisture in the silo. 4 Packset is the agglomeration of mineral coating on the media which reduces the crushing effect. 4 Using an additive increases flow by reducing ball ...

Get Price -

NOVEL COMMINUTION MACHINE MAY VASTLY IMPROVE CRUSHINGGRINDING EFFICIENCY

Grinding mechanical efficiency is greater than 90% – no eccentric; minimal gearing 4. Inpit crushing and underground versions are possible 5. Rock is fractured with high compressive force exerted by the hammer ring on a packed particle bed 6. Rock is comminuted in a compressed bed of particles similar to HPGR, but with a lower wear rate 7.

Get Price -

crushing grinding aspects

Grinding vs Crushing Grains and What Aspects of ... Click to view on Bing39:39. Oct 19, 2018 · Howdy and happy Friday, homebrewer! Episode 105 is here and ready for your listening and viewing pleasure! Todd is out in Wyoming hunting antelope (or, trying to hunt antelope as we'll explain in ... Author: Homebrew Happy HourGet price

Get Price -

aspects and impacts of rock crushing

· Crushing 101 – Different types of crushers for distinctive, Know More. Dec 17, 2020· Impact crushers are traditionally classified into two main types, horizontal shaft impact (HSI) crushers and vertical shaft impact (VSI) crushers These different types of impact crushers share the crushing principle, impact, to reduce the material to smaller sizes, but features, capacities .

Get Price -

Grind.

After multiple, multiple effects of the composite crushing, if the material particle size is less than the punch plate and the gap between the head, will be discharged from the lower part of the housing discharge; if greater than the gap, will be rigid hammer milling and grinding Cut off until unloaded. Can basically complete the construction materials required for solid material .

Get Price -

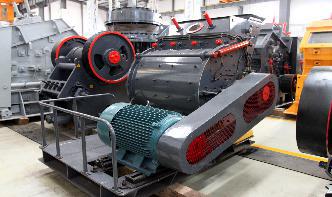

Mobile Crusher

K Mobile Crushing Plant. K Series Mobile Crushing Plant contains 7 series and 72 models. There is always one for you. It is optimized and innovated in the aspects of structural design, equipment configuration and combined appliion, so as to realize more flexible combinations

Get Price -

HAMMER CRUSHER | Crushing/Grinding | CO., .

Easy Maintenance. Multisectional welded housing allows easy access to every partition and quick exchange of wear parts. Hammners are always operated with sharp edges. And high utilization of hammer head with continuous operation is achieved by reversible rotation.. No cleaning in the grinding chamber is required because hammer head with ...

Get Price -

Crushing Your Pills? Absolutely

Crushing them to a powder will allow your digestive enzymes to work on the active ingredients in vitamins and mediions alongside other ingredients such as DCP's. If not crushed, your digestive enzymes may never even get a chance to breakdown much of the active ingredients and thus limiting their effectiveness. There are many types of pill crushers on the market ranging in .

Get Price -

The Swebrec function: linking fragmentation by blasting and crushing

and associated individual crushing and grinding breakage functions. The approach uses a matrix description of the product flow through the system and a onefamily description of breakage functions based on the t 10 concept. t 10 is that part of a given size fr action of material subjected to a drop weight crushing test, which

Get Price -

Home

RPM Reliable Process Maintenance delivering nothing but the best. RPM is a reliable progressive company that focuses on delivering solutions to clients. We specialise in fabriion, machining, fixed plant maintenance and refurbishment to the mining and mineral processing industries. RPM also works heavily in the recycling, timber processing ...

Get Price -

HSE

This guidance is for all those with responsibilities for the operation of mobile crushers, including contract managers, supervisory staff and operators of these machines. It covers the safe operation of the mobile crushing operation and includes guidance on clearing blocked crushers. This guidance cannot cover every risk and is not comprehensive.

Get Price -

Homebrew Happy Hour: Grinding vs crushing grains and what aspects .

Grinding vs crushing grains and what aspects of homebrewing we are currently focused on! Grinding vs crushing grains and what aspects of homebrewing we are currently focused on! Oct 18, 2018. × About the Podcast. Homebrewing beer is a favorite pastime for many Americans and is one of the fastest growing hobbies in the country! With that being said, you probably have a .

Get Price -

What is Grinding?

· To produce desired fineness of end products, grinding is done after crushing. For example, through crushing the mineral ore to below a certain size and finishing by grinding it into powder, the ultimate fineness depends on the fineness of dissemination of the desired mineral. Grinding can be done wet or dry, depending on the process in use, but for dry .

Get Price -

All crusher types for your reduction needs

There are two basic types of jaw crushers: single toggle and double toggle. In the single toggle jaw crusher, an eccentric shaft is on the top of the crusher. Shaft rotation causes, along with the toggle plate, a compressive action. A double toggle crusher has two shafts and two toggle plates. The first shaft is a pivoting shaft on the top of ...

Get Price