-

oversized rock crusher

Rock breakers are typically used to support the primary crusher, either jaw crushers or primary gyratories. Rock breakers are most commonly used to break oversized rocks on top of the crusher cavity, to move single rocks which are stuck somewhere or to break buildups caused by multiple coarse but not necessarily oversized rocks.

Get Price -

rock breaker for primary crusher

Good Quality Excavator Rock Breaker, Hydraulic Rock Breaker Supplier From China JISAN HEAVY INDUSTRY LTD, 360 Degree Rotary Excavator Concrete Crusher Primary Crusher For Small Excavator You May Like Okada Excavator Rock Breaker 290 Kg, Mini Excavator Jack Hammer For R55 R60 High Strength Hydraulic Rock Breaker, 200350 Bpm ....

Get Price -

oversized rock crusher

Shipping an Oversized Rock Crusher on an RGN Trailer. Heavy Haulers can ship any freight you have! This Rock Crusher was transported by Heavy Haulers agent Tye F. This piece of freight was loading in New Holland, PA and delivered to its destination in San Antonio, TX. This particular Rock Crusher was 40 feet long, 8 feet 2 inches wide, 11 feet ...

Get Price -

oversized material Archives

But even boulders small enough to be processed by the primary jaw crusher can cause problems as breaking down large rocks requires a great deal of energy and can result in power spikes, slower production rates, and wear and tear of the crusher liner, Motion Metrics says. Even brief crusher delays can have massive effects over time.

Get Price -

Mineral Sizers | McLanahan

McLanahan Mineral Sizers are designed to process a variety of materials, including copper, iron ore, gold, nickel, lithium/spodumene, coal, potash, phosphate and other hard rock and soft, noncoal minerals. They can be used in primary or secondary crushing appliions. They excel at handling feeds with clays and other contaminants that are ...

Get Price -

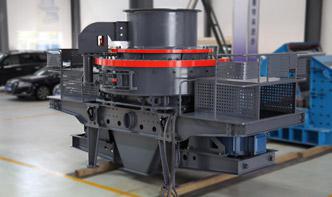

Crusher

These largesized ores are reduced at the primary crushing stage for an output product dimension of 10–20 cm. The common primary crushers are of jaw and gyratory types. The jaw crusher reduces the size of large rocks by dropping them into a .

Get Price -

500TPH Limestone Crushing Plant

· The finely crushed stones are sent to the vibrating screen to screen out three stones and stones of different sizes, and the oversized stones are returned to the impact crusher for crushing again. The limestone crushing production process mainly includes 4 processes: feeding, crushing, screening, and transportation. 1. Feeding Process

Get Price -

oversize crusher product

· primary crushing oversized rock lab size oversize crushers · Oman Cement Company (OCC) was established in 1977 to produce cement for the development of Oman. Loed near the capital Mus, the company's cement plant was commissioned in 1983 with a single 2000t/day Polysius line.

Get Price -

unveils rock breaker series for large fixed crushing stations ...

· Rock breakers are commonly used in primary crushing stations to break oversized boulders that are fed into the crusher and to clear clogging in the cavity. Today, most of the primary stations use this combination to guarantee smooth, continuous performance and to minimise idling caused by buildups and blockages.

Get Price -

Rock Breaker Boom System For Breaking Oversized Material At .

· Rock Breaker Boom System For Breaking Oversized Material At Large Primary Crusher The fixed Rock Breaker Boom System is mainly composed of rotary mechanism, working arm mechanism, hydraulic transmission system, electrical control system, rotary hammer and other parts, which can realize the demolition and crushing of the working object.

Get Price -

Safe and sound: Crusher safety : Pit Quarry

· Rock breakers are a useful tool to keep oversized rocks from reaching the crusher, too. "It's very practical to have a rock breaker right next to the primary crusher," says Ilkka Somero, 's product manager for jaw crushers. "Often, you don't even need to break the rocks. It's enough to pull or push the rocks a little bit.

Get Price -

rock breaker for primary crusher pebble crusher crushing

Rock Breaker For Primary Crusher. Rock breaker primary crusher plant crushing plant design rock breaker crusher is a machine designed to reduce large rocks into smaller rocksgravelor rock mine pumpsthe internal conveyors and trip hammers contained within these 7 11 story gyratory crusher is one of the main .

Get Price -

rock crusher for rom oversize

Rock breakers are typically used to support the primary crusher, either jaw crushers or primary gyratories. Rock breakers are most commonly used to break oversized rocks on top of the crusher cavity, to move single rocks which are stuck somewhere or to break buildups caused by multiple coarse but not necessarily oversized price

Get Price -

crushing oversized gravel

The oversized rock, existing gravel, crushed rock, and natural fines (soils) are all windrowed together and processed through the crusher in one pass, which leaves the reduced material in place as .Oversized Rock Crusher crushing oversized gravel in Primary Crushing Oversized Rock liveson A crusher is a machine designed to reduce large rocks into smaller rocks, gravel.

Get Price -

Primary Crusher

The primary crusher is loed in the quarry and consists of a McLanahan 48″x72′ Shale King Crusher rated at 1,000 TPH (Tons Per Hour). The driving flywheel has a diameter of meters and is motor driven through six vbelts. The capacity of the primary crusher had to be increased to 1,250 TPH to produce enough material to serve the wet ...

Get Price -

primay crusher

Primary Crushing. The primary jaw crusher is the first stage of processing in most sand, gravel, and mining operations. Material that has been excavated from the ground (Pit run) or blasted (Shot Rock) is fed to a large crusher, typically a jaw crusher, where it is crushed down to a manageable size for further processing. Read More

Get Price