-

Flexible Operation of Coal Fired Power Plants with Post .

Economic tradeoffs between improving transport and storage scheme flexibility and constraining power plant operations should also be carefully analyzed, particularly if the captured CO2 is to be used in another process such as enhanced oil recovery. Another important aspect of real plant operation will be adhering to legislative requirements. Further work is required to .

Get Price -

Coalfired power station

A coalfired power station or coal power plant is a thermal power station which burns coal to generate electricity. Worldwide there are about 8,500 coalfired power stations totaling over 2,000 gigawatts capacity. They generate about a third of the world's electricity, [1] but cause many illnesses and early deaths, mainly from air pollution.

Get Price -

Operation and Maintenance of Coal Handling System in Thermal Power Plant

Operation and Maintenance of Coal Conveying System Screening and Crushing Coal Machinery in Thermal Power Plant Lihua Zhao, Ming Liu Engineering 2013 This paper based on our country current coal conveying system in thermal power plant, on the basis of typical screening and crushing mechanical equipment of analyzes the broken mechanics principle,. 1

Get Price -

Implementation Of Quality Management System For Coal Handling Plant .

The process of the CHP involves coal receipt from various systems and then unloads the coal at various unloading stations (See figure No 4). Then the coal is process as per requirement. After the processing it is to be transferred to bunker or stack yard. For controlling all these process the processes are equipped with control system.

Get Price -

Job: Operation Engineer

Responsible for coal receiving from mines, crushing, washing,blending and distich to power plant through CCPC. Ensure smooth operation of CPP equipment from control desk as per SOP ; Ensure for proper utilization of system to maximize coal receiving and dispatch. Ensure defect notifiion in SAP and follow up for corrective action.

Get Price -

Cost analysis of a coalfired power plant using the NPV method

· The operating cost (includes the purchasing cost of coal feedstock, maintenance and labour, insurance and cost of power associated with boiler feedwater pumps and condensate extraction pumps for running the thermal power plant) is considered to be paid annually over the lifespan of the coalfired power plant.

Get Price -

Coal preparation plant

The more of this waste material that can be removed from coal, the lower its total ash content, the greater its market value and the lower its transportation costs . Contents 1 Runofmine (ROM) coal 2 Handling 3 Sampling 4 Washability 5 Crushing 6 Screening 7 Gravity separation Jigs Dense medium process Dense medium baths (DMBs)

Get Price -

Cost and Benefit Analysis of Desulfurization System in Power Plant

power plant operation, which increases the operating costs. The implementation of the desulfurization power price policy brings certain economic compensation and stimulate the operation enthusiasm of desulfurization system. However, with the fierce compete, the power generation hours dropped, the desulfurizer price raised, the coal quality became lower, so the .

Get Price -

List of Coal PowerPlants

· Weyerhaeuser Pine Hill Operations Coal Power Plant AL USA : : United States of America : Alabama : Widows Creek Coal Power Plant AL USA : : United States of America : Alabama : Aurora Energy LLC Chena Coal Plant AK USA : 29 : United States of America : Alaska : Eielson AFB Central Heat and Power Plant Coal Plant AK USA : : .

Get Price -

HOW ELECTRICITY IS PRODUCED AT A COALFIRED POWER .

The mixture of pulverised coal and hot air is blown into the furnace through the front and rear walls of the boiler via 36 fuel injection ports, or burners. Here it ignites to create a fireball. Two forced draught fans supply atmospheric air, preheated in air heaters to approximately 250ºC, as combustion air to the boiler.

Get Price -

Life Cycle Assessment of Coalfired Power Production

three systems were examined: 1) a plant that represents the average emissions and efficiency of currently operating coalfired power plants in the (this tells us about the status quo), 2) a new coalfired power plant that meets the new source performance standards (nsps), and 3) a highly advanced coalfired power plant utilizing a low .

Get Price -

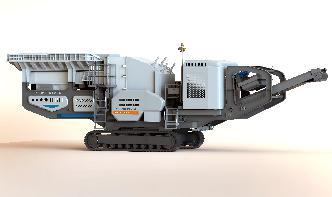

Coal Power Plant Equipment | Power Station Engineering

Coal Power Plant Equipment | Power Station Engineering Improve Efficiency, Operation and Consumption with the Goal of Reducing Operation Maintenance Spending SELECTIVE CATALYTIC REDUCTION (SCR) DELTA – DSI DRY SORBENT INJECTION CIRCULATING DRY FLUID BED SCRUBBER (CDS) REGENERATIVE SCR (RSCR) WET FLUE GAS .

Get Price -

Environmental impacts of coal

Thermal pollution from coal plants is the degradation of water quality by power plants and industrial manufacturers when water used as a coolant is returned to the natural environment at a higher temperature, the change in temperature impacts organisms by decreasing oxygen supply, and affecting ecosystem composition. [29]

Get Price -

The digital power plant of the future | McKinsey

· Powerplant digital transformations face common pitfalls. Thermal generation still dominates the global fuel mix, with coal and gas making up 62 percent and representing 16 petawatthours (PWh) today. Our research shows coal and gas contribution to the fuel mix will stay constant until 2030, after which it will decrease toward 2050 (Exhibit 1).

Get Price -

Cost analysis of a coalfired power plant using the NPV method

· The operating cost (includes the purchasing cost of coal feedstock, maintenance and labour, insurance and cost of power associated with boiler feedwater pumps and condensate extraction pumps for running the thermal power plant) is considered to be paid annually over the lifespan of the coalfired power plant. It is likely to be changed in an economic climate ( .

Get Price -

CO2 Emissions from CoalFired and Solar Electric Power Plants

CoalFired and Solar Electric Power Plants F. Kreith D. Brown May 1990 Prepared under Task No. Solar Energy Research Institute A Division of Midwest Research Institute 1617 Cole Boulevard Golden, Colorado Prepared for the Department of Energy Contract No. DEAC0283CH 10093 . NOTICE This report was prepared as an .

Get Price