-

belt conveyor design guide

FLAT WIRE CONVEYOR BELT TECHNICAL MANUAL. TROUBLESHOOTING GUIDE 11 GLOSSARY OF TERMS 14 HOW TO IDENTIFY A BELT 15 KEYSTONE MANUFACTURING INC. BOX 270 668 CLEVELAND STREET ROCHESTER, PA Phone: Fax: EMail: [email protected] Website: .

Get Price -

Buying Guide – How to Choose the Right Belt Conveyor Design

· The conveyor engineering team working on the device will probably have to decide on them. Like the linear slide system, you will need an expert opinion to choose the belt conveyor design process. If you need a custom design, you may check out Robotunit's just in time conveyor technology for high quality and faster lead time.

Get Price -

Conveyor Belt: What Is It? How Does It Work? Types, Parts

The design of modular belt conveyors makes it easier to clean, and the material is resistant to sharp and abrasive substances. Modular belt conveyors come in varying configurations and use a single belt to go around corners, in a straight line, up .

Get Price -

Belt Conveyor

Belt Conveyor. Our pursuit and company purpose is always to "Always satisfy our consumer requirements". We keep on to acquire and style and design remarkable highquality products for each our outdated and new customers and reach a winwin prospect for our consumers as well as us for Belt Conveyor, Table Top Chain, Conveyor Side Guide Brackets ...

Get Price -

Screw Conveyor Engineering Guide

Primary considerations for the selection of a screw conveyor are: Type and condition of the material to be handled, including maximum particle size, and, if available, the specific bulk density of the material to be conveyed. Quantity of transported material, expressed in pounds or tons per hour. The distance for which the material is to be ...

Get Price -

MDR Belt Design Guide

This design guide has been created to convey best practices for utilizing motorized rollers in belted appliions. When applied properly, the motorized roller zone offers many benefits over a standard roller conveyor zone. After reviewing this belt guide, one should be able to: n Select a belted zone configuration based on conveyor requirements

Get Price -

Reversible Conveyor Design Guidelines

· 5) The skirt board will be open at both the ends. 6) The belt force on nondrive pulley can be considered 2 x (Belt Tension T1). 7) If conveyor is inclined, then drive size will be considering material movement for uphill situation. 8) Conveyor can .

Get Price -

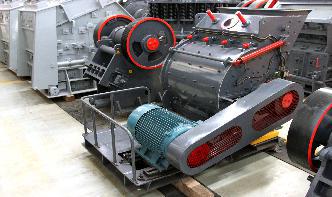

Belt Conveyor

Belt Conveyor. Belt conveyor is necessary in the production line of gravel and construction waste, and is mainly used to connect the broken equipment of different levels, sand production facilities, and screening equipment. It is also widely used in cement, mining, metallurgy, chemical, foundry, and building materials industries.

Get Price -

Dunlop Conveyor Belt Design Manual

· Conveyor Belt Design. Step By Step Example of Belt Tension Calculation. Table 1: Table of Symbols. Table 2: Material Characteristics. Table 2 (a): Typical Flowability. Determination of Conveyor Capacities. Table 3: Capacities of Troughed Belt Conveyors. Table 4: Recommended Maximum Belt Speed for Normal Use.

Get Price -

Power Belt Conveyor Selection Guide | Ashland Conveyor

Ashland Conveyor offers a standard line of Slider Bed and Roller Bed Power Belt conveyors. Both are also available as incline conveyors. The Slider Bed Box Frame belt conveyor is the most economical conveying solution while Roller Bed will convey heavier loads than a Slider Bed. All of our standard powered conveyors come with a 1/2HP motor.

Get Price -

Conveyor Safety

Constant vigilance, appropriate training, and welldesigned conveyor systems which have safety features embedded in the design itself are vital to keeping your team and facility safe. Get in touch with our team of experts at Compactor Management Company and know more about how you can boost the safety quotient of your facility when it comes to conveyor systems.

Get Price -

Design, Analysis and Optimisation of Belt Conveyor for Coal

· In order to optimize the conveyor equipment for efficient performance these parameters are reduced such as Reduction of motor frame vibrations to 11. – 16 Hz, reducing idler deflection to less than 5 mm, maximum shaft deflection to be achieved less than 1 mm, reduce the belt capacity to 31 TPH, reduce the overall conveyor weight to TON.

Get Price -

Self Tracking Belt

For Conveyor Design Guidelines click here SelfTracking belt (STB) is available in widths up to 3,000mm; open areas from 0% to nearly 70% are possible. With a flat surface and minimal opening between wires possible, it is particularly suitable for small and delie products.

Get Price -

belt cconveyor design guide

Pulley Design Features. Pulley Hub Design. Shafting. Pulley Lagging. In belt conveyor appliion, a pulley's purpose is primarily threefold, 1) support the belt in directional changes, as designed in the conveyor, 2) transmit driving power to the belt, and 3) guide or train the belt.

Get Price -

Belt Conveyor Structural Design

· Experts, What standard do your companies use in the design of the structures that support belt conveyors? The structural verifiion itself isn't really an issue. The loads and load combinations, however, can create some interesting discussions. The belt conveyor isn't a building to be designed as per ASCE 705 or AISE Nr 13 and neither is a mobile machine to .

Get Price -

POWERED ROLLER CONVEYOR DESIGN GUIDELINES

Design type Drive side Belt side Straight without side guide Straight with side guide Curve Tube materials (Roller Conveyor Straight) Standard Alternative Steel galvanized Stainless steel PVC rubber coated (2mm – 3mm thickness) PU rubber coated (2mm – 3mm thickness) (wrench size 14) Torque support Spring loaded axle, hexagonal

Get Price