-

mechanisms of vertical milling machine

17/12/2021 · Oct 28, 2010· Cutting Tool Appliions Chapter 13: Milling, shafts, pumps and shifting mechanisms,, Collets— On some vertical milling machines the spindle .... CNC Milling Service | eMachineShop

Get Price -

vertical milling machine mechanisms of movements

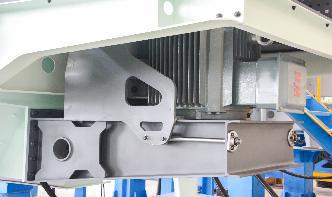

vertical milling machine mechanisms of movements T19:04:56+00:00. ... Vertical Milling Machine (Refer Fig. ): Vertical milling machine is so called, because of the vertical position of the cutterspindle. The table movements are horizontal, transverse and vertical. In this case, overarm is small and provides a strong support for ...

Get Price -

mechanical mechanisms of vertical milling

Milling machine parts and their functions studentlesson. Milling head: The milling head is the upper part of a vertical mill machine. It consists of spindle, driving motor and other controlling mechanisms. Ram: The milling machine part can move transversely (in and out) on the column by a hand level.

Get Price -

Differences Between Of Horizontal And Vertical Machining Center

28/10/2020 · While the worktable of the vertical machining center is usually a Tslot table style that has a cross slide design. Also, they have two types of motion mechanisms controlling the vertical directional movement of the table. The worktable of Xfeed is sheltered by the rail controller for Yfeed on. 4. Chip removal

Get Price -

Cutting Tool Appliions, Chapter 13: Milling Methods and Machines .

29/06/2020 · The vertical slide mates with the slide on the front of the column, and the horizontal slide carries the saddle. It contains the necessary gears, screws and other mechanisms to provide power feeds in all directions. The operator can select various feedrates through the controls mounted on the knee.

Get Price -

(PDF) Mechanics of Machinery I | Tareq shaban

it consists of 4 rigid bodies (called bars or links), each attached to two others by single joints or pivots to form a closed loop. if each joint has one rotational degree of freedom (, it is a pivot), then the mechanism is usually planar, and the 4bar is determinate if the positions of any two bodies are known (although there may be .

Get Price -

CNC Milling Machine Axis Explained [Complete DIY Guide]

Milling Machines tend to use premade Linear Slides such as these: Linear Slide Rail with Travelling Block. The rail is cut to length and can hold as many travelling blocks as you like. In most designs, there are two travelling blocks per rail and 2 rails per axis. Leadscrew The Leadscrew converts the rotary motion of the motion to linear motion.

Get Price -

Milling Machine

In Vertical milling machine, the position of the spindle head is vertical and the axis of the spindle is perpendicular to the work table. In this both the base and column are integral casting. The vertical milling machine may have fixed head or swiveling head or slidable head spindle. The spindle head can be moved up and down over the guideways.

Get Price -

Slotter Machine: Parts, Types, Operations, Mechanism, and .

The machine operates vertical, Horizontal and at Some angle too (Inclined Surfaces). Irregular surface machining. Machining operation of Dies and Punches. The operation like slots, grooves, splines, and keyways for both internal and external surfaces. Internal and external gear teeth machining. Machining Operations of a Slotter Machine

Get Price -

vertical bench milling machine

Vertical Machine Vertical BR5060 BR7080 Single Column High Speed Vertical Cnc Lathe Machine Vertical Turning CNC Vertical Lathe Machine 40,/ Set 1 Set (Min. Order) 6 YRS CN Supplier (17) | "Professional factory" Contact Supplier Ad 1/6 700*180mm table size small vertical milling machine Up to 5 years warranty Highprecision

Get Price -

mechanisms of vertical milling machine

What Is a Vertical Milling Machine? Most vertical milling machine tools come with a combination of automatic and manual controls. On the automatic side, the operator is able to change the speed of the cutting mechanism, decide whether the cutter should go in forward or reverse, and control the on and off switch.

Get Price -

mechanisms of vertical milling machine

Mechanisms Of Vertical Milling Machine. 2020 10 27 1902 article brown sharpe mfg. Mechanisms of vertical milling machine. Milling machine parts and workingmech4study. may 13 2016 spindle is the main part of the machine which hold tool at right place in vertical milling machine and hold arbor in horizontal milling machine it is a moving part which is in rotary .

Get Price -

Benchtop Milling Machines

22/02/2010 · There are two general classifiions of the milling machine which include the vertical milling machine and the horizontal milling machine. Although these two general types are similar in function, the mechanisms differ, specifically the feeding process of the work pieces, and the orientation of the axis.

Get Price -

Milling Operations and Milling Machines; Definitions, Terms, Types

01/07/2022 · In a typical milling machine, there is a spindle that holds the cutting tool. And there is a worktable that holds the workpiece. The spindle rotates to rotate the cutting tool. And worktable moves to make the feed motion. All the machinery that constitutes this contraption is .

Get Price -

Ahsanullah University of Science and Technology (AUST) .

(B) Vertical Milling Machine Column :The column houses the spindle, the bearings, the gearbox, the clutches, the shafts, the pumps and the shifting mechanisms for transmitting power from the electric motor to the spindle at a selected speed.

Get Price -

Milling Machine Repairs

Milling machine repairs including spindle rebuilding repair services. Repair capabilities include adjusting to .00005 tolerances, vibration analysis, motorized spindle testing up to 95 A, 460 V, 3000 Hz, 50 hp 2 tons in weight, beltdriven spindle balancing repair documentation.

Get Price -

Milling machine with horizontal and vertical spindles

19/08/1999 · The most popular and ubiquitous milling machines, bedmills, and machining centers have a construction in which the vertical axis of spindle movement is constrained and guided by a column portion of the machine structure which is itself fixed to the machine base.

Get Price -

Vertical Milling Machine

Vertical Milling Machine This study guide will cover the major working parts, functions, and machining techniques that can be found/used on most vertical milling machines. This study guide has been designed to directly represent the questions that will be found on the open book written assessment and as an aid for the handson usability assessment.

Get Price -

A New 3DOF Spatial Parallel Mechanism for Milling Machines with .

01/01/2005 · Hexaglide and Triaglide mechanisms are examples where workspace extension is achieved by elongating one axis as a principal motion axis that is a common feature of all Cartesian machines. With the idea of principal axis of motion in mind, a new 3DOF spatial parallel mechanism for horizontal and vertical milling machines has been developed.

Get Price -

What is a CNC Milling Machine How Does it Work? (2022)

09/11/2021 · All units and mechanisms are mounted on the bed (1), while the workpiece is fixed on the work table (2). Depending on the design of the CNC milling machine, the working table moves along the guides (3) in the longitudinal and/or transverse direction. To process the workpiece, a milling cutter or other cutting tool is used.

Get Price -

mechanisms of vertical milling machine

CNC Milling Machines are the machines in which the milling operation is being controlled by software. It has increased the overall production with better finish and accuracy. High Accuracy: In the milling machine, the products machined are of high accuracy especially in the case of the most advanced form of milling machine which is the CNC Machine.

Get Price -

Specifiion of Vertical Milling Machine | Download Table

this could be due to high temperature generation due to faster tool penetration which leads to thermal softening resulting minimal exit burr height till intermittent feed range, subsequently due to...

Get Price -

Machine Shop 3

The ramstyle vertical milling machine, because of its simplified construction, has only two basic areas in need of lubriion. The head and the way surfaces. The head of the ram style vertical mill has two oil cups (Figure 10) that need to be checked and/or filled before every use. Figure 10.

Get Price -

Machine Tool | Definition, Types, Classifiion of Machine tool

The physical functions of a machine tool in machining are: Firmly holding the blank and the tool. Transmit motions to the tool and the blank. Provide power to the toolwork pair for the machining action. Control of the machining parameters,, speed, feed and depth of cut.

Get Price