-

Technical Features Of Impact Crusher Compared With Hammer

Technical Features Of Impact Crusher Compared With Hammer. Features Of Impact Crusher Hammer Features of impact crusher hammer technical features of impact crusher compared with hammer impact crusher is a kind of crushing machine that uses the plate hammer of the high speed rotating rotor to crush the materials at a high impacting crushing force when the .

Get Price -

KNIFE MILL COMMINUTION ENERGY ANALYSIS OF SWITCHGRASS.

· Direct mechanical power inputs were determined using a dedied data acquisition system for knife mill screen openings from to mm, rotor speeds between 250 and 500 rpm, and mass feed rates from 1 to 11 kg/min. A speed of .

Get Price -

Fine Grinding With Impact Mills

· With impact comminution, the kinetic energy of the particles is employed to generate the requisite degree of deformation. In the linear range, the deformation is elastic and reversible. As soon as higher stresses occur, the material strength .

Get Price -

NOVEL COMMINUTION MACHINE MAY VASTLY IMPROVE CRUSHINGGRINDING EFFICIENCY

NOVEL COMMINUTION MACHINE MAY VASTLY IMPROVE CRUSHINGGRINDING EFFICIENCY ABSTRACT A Conjugate AnvilHammer Mill (CAHM) has the potential to replace conventional crushers and SAG mills, with their respective conveyors and stockpiles, in a SABC circuit. It may improve comminution circuit efficiency by .

Get Price -

Comminution and mechanochemical activation in oxide ceramics .

· In summary, it best to use the following for comminution (particlesize reduction) and MCA of the rawmaterials components to obtain ceramic articles: 1) mills with impact (pressure) — shear loading, since they give nearly spherical particles with high dispersity and high specific surface area; 2)

Get Price -

Vibration Mill: Components, Advantages and Disadvantages of .

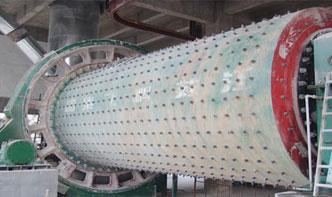

· Vibration mills are similar to ball mills in that particles of the materials are crushed between porcelain or metal balls and the mill body. Drugs and excipients are readily ground to less than 5 mm, the grinding time being considerably less than is required in normal ball milling. As a result, the efficiency of the comminution process in ...

Get Price -

comminution features in an impact hammer mill

cementcement plant impact hammer mill. 0183 32 Abstract A systematic study on the comminution of a soft coal and a hard iron ore material is carried out to investigate the bulk comminution features of the hammer mill The effect of the feed rate and the rotor speed on the mill efficiency in terms of reduction ratio, energy expenditure, fines produced and median size .

Get Price -

Solids and powder milling

Impact Mills: Hammer mills Pin mills Universal mills: The size reduction is ensured here by impacting the product against a solid surface. The solid surface is actually made by different kind of beaters rotating at very high speed. A pin mill is equipped with a static disc mounted with several pins and a mobile one also mounted with pins. When the product is forced passing .

Get Price -

[PDF] PERFORMANCE EVALUATION OF TWO DIFFERENT HAMMER MILLS FOR GRINDING ...

The hammer mill was designed and constructed from locally available materials for grinding grain particles such as maize, millet, guinea corn and other coarse materials of cassava tuber, yam tuber,. Expand 14 PDF View 1 excerpt, references background Save Alert The Influence of Hammer Type Used in Grinding Mills on Grist Fineness M. Muntean

Get Price -

Strength And Features Of Hammer Mill

The hammer mill crushes by the collisions between highspeed hammer and material, and the hammer crusher features in its simple structure, high reduction ration, high efficiency, etc. The PC hammer crush (hammer mill) was developed for both dry and wet crushing of brittle,mediumhard materials for the mining, cement, coal, hammer mill – series 6. .

Get Price -

General Features Of Grinding Mill

Feeding, making metering into the mill difficult, grinding, plugging the hammer mill screen or blocking the air classifier ofet mill, and collection, plugging the bag filters. there are two ways to grind sticky materials. the first solution is to dry the material prior to grinding, or dry and. Live Chat. Airflex Product Line Cp3131 Grinding Mill Torque. Grinding mill clutches in ...

Get Price -

Comminution machines

Examples of comminution machines include agitator ball mills, colloid mills, cutting mills, disk mills, homogenizers, jet mills, mechanical impact mills, ringroller mills, and roll crushers. [] The capacities of comminuting machines are best discussed when the individual types of equipment are described.

Get Price -

Comminution | PDF | Mill (Grinding) | Industries

• Comminution is accomplished by a sequence of crushing and grinding processes. • Crushing is accomplished by compression of the ore against rigid surfaces, or by impact against surfaces while grinding is accomplished by abrasion and impact of the ore by the free motion of unconnected media such as rods and balls and the ore itself.

Get Price -

hammer mill speed torque characteristics

Comminution features in an impact hammer mill ScienceDirect Feb 01, 2013· The − 100 + 40 mm feed particles were crushed in the hammer mill under different levels of the feed flow rate and rotor grate with a 20 mm opening was used at the discharge, tests were also carried out after removing the grate to study the effect of the grate on the generation .

Get Price -

hammer mill features

Vertical mill is also a hammer mill, its main features are: 1. It adopts a hundred moving feeder with three functions of iron removal, stone removal, and automatic feeding. 2. The material splitting device distributes the materials evenly and sends them to the feed inlet, so that the crushing process is even and easy. 3. The rotor is equipped with guide vanes to improve the .

Get Price