-

An environmentally friendly ball milling process for recovery of ...

· after comilling with k{sub 2}s{sub 2}o{sub 8}/nacl, soluble metallic compounds were produced and consequently benefit the subsequent leaching process. % of cu and % of pd in the ewaste particles could be recovered in mol/l diluted hcl in 15 min. ag was concentrated in the leaching residue as agcl and then recovered in 1 mol/l nh{sub .

Get Price -

Reducing the health risks of the copper, rare earth and cobalt

This paper considers the health and environmental burdens and impacts of the extraction and refining of selected metals (copper, rare earth elements and cobalt) and how impacts can be reduced through the transition to a circular, lowcarbon economy. Performance in the global industry is extremely variable.

Get Price -

「information on milling process copper mines」

23/04/2019· Information On Milling Process Copper mainly produces five series of products, including crushing equipment, sand making equipment, mineral processing equipment, grinding equipment and building materials equipment. 40 years of mining machinery manufacturing history, three production bases, exported to more than 160 countries and .

Get Price -

copper milling process

Feb 03, 2012· Nanocrystalline Nb 3 (Al 1x Ge x) mixtures with x = 0, and 1 were fabried by E. Pusceddu et al[61] by wet mechanical milling using copper milling media and distilled water as a process control agent (PCA) with the intention of improving the yield, properties and the performance of these materials. Very high yields of nanocrystalline ...

Get Price -

Dry milling machines | Schenck Process

They are are characterized by their excellent wear life, high availability and easy maintenance. At the other end of the scale we have ultra fine mills that will grind powders down to 2 microns ( mm). Continuous improvement of milling performance We design your customized milling systems using the latest engineering techniques.

Get Price -

Vibration measurements for copper ore milling and ...

Flow fluctuation in spiral classifier underflow during constant throughput The presented strategy of throughput control guarantees the expected quality of feed sent to flotation process. However, during tests made in concentrator plant in Lubin it was noticed that separation of coarse particles from fines in spiral classifier causes the fluctuation of mass flow in underflow and overflow .

Get Price -

Chapter 7 Energy Use in the Copper Industry

The cutoff grade6 used in mining determines: 1 ) how much ore and waste have to be transported, 2) how much ore is milled or waste is available for dump leaching operations, and 3) from the ore that is milled, how much copper is recovered .

Get Price -

Economic of Copper Processing

· effective costs of copper processing example of porphyry copper mine processing costs assuming a freight cost of £ 20/ton of concentrate, the total deduction are £ ( + + ) = £ the nsr per tonne of ore treated is thus as mining, milling, and other costs must be deducted from this figure, it is apparent that this mine with .

Get Price -

Cnc Machining Process Flow Chart

· The other kind of machining equipment is a CNC milling machine. This kind of machine is used to shape and cut objects. The main difference between a lathe and a milling machine is the fact that a milling machine has a rotating spindle while a lathe doesn't have one. Also, a milling machine has a much larger spindle than a lathe does. It is ...

Get Price -

copper milling equipment process flow diagram copper milling

copper milling equipment process flow diagram. About copper mine mill flow diagramrelated information the chemistry of copper heap leaching john dreier november, 1999 introduction between 1980 and copper rolling mill process flow chart B Series Deep Rotor VSI Crusher is a new type sand crushing machine, which introduces German technology Get chatRead more .

Get Price -

Highlyefficient laser ablation of copper by bursts of ultrashort ...

· However, it was still 40% lower than the ablation rate for laser milling achieved in our study. In paper 28, the punchingmode processing in the burst regime was utilised for copper and efficiency...

Get Price -

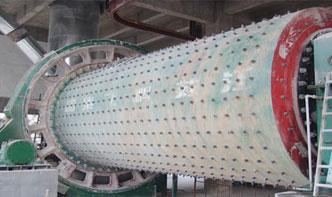

copper mine milling process equipment

Process Flow Gold Mill Prompt Caesar is a famous mining equipment manufacturer wellknown both at home and abroad, major in producing stone crushing equipment, mineral separation equipment, limestone grinding equipment, etc... diagram of belt copper ore ball mill equipment. Apr 02, 2018 0183 32 Easy operating Raw Ore,Limestone Ball Mill, Find Complete Details .

Get Price -

flow chart of copper milling

Machining copper Practical Machinist. Feb 28, 2010· I have found that full cream milk is the best cutting fluid for copper both milling and turning don't use skim as it needs the fat content. You will need to experiment with your speeds and feeds. What kind of cuts do you need to make to get it to size and how thick is the material ? . Get Price

Get Price -

Process flow diagram of palm oil mill plant

· A process flow diagram (PFD) is a diagram commonly used in engineering to indie the general flow of plant processes and equipment. The palm oil processing process flow diagram displays the relationship between major equipment of a plant facility and does not show minor details such as piping details and designations. The Process Flow Chart ...

Get Price -

Olympic Milling | Home Page

The business of Olympic Milling Group ("OMG") has since successfully grown and diversified over the decades from the original maize milling plant loed in the Copperbelt town of Mufulira, into a leading diversified Zambian group with business interests in flour and maize milling, animal feed manufacturing, arable farming, copper and hydro power.

Get Price -

Productos – Asarco

Compared to other metals, copper is very ductile, meaning that it can be drawn through a tiny hole into very fine wire without breaking. Refining improves the ductility of copper so that extremely fine wires can be drawn. Impurities increase the chance that the wire will break during the drawing process. Copper conducts electricity.

Get Price -

Experimental investigation and processing optimization for micro ...

· Then, the formation mechanism for different kinds of burrs in micromilling of copper clad polyimide is analyzed. Furthermore, the burr height prediction model is established, and the optimized...

Get Price -

From Ore to Finished Product

Copper ore is extracted using two basic methods of mining open pit or underground mining. 3. Processing of Copper Ore The first step in processing the ore removed from the mine is to break the large rocks of ore into smaller pieces. This is accomplished by a variety of subsequent processing steps. 4. Beneficiation of Copper Ore

Get Price -

copper milling process 」

Copper is a very difficult metal to machine and requires specialized process knowledge for manufacturing. Copper alloys are often used in place of pure copper to improve machinability, especially when performing more intrie custom work. As such, specialized knowledge and expertise is necessary when machining copper on 5 axis equipment.

Get Price -

Shalina Resources

Leaching. Helps to increase the residence time for better leaching efficiencies of Copper and Cobalt. CCDs: Improves the post leach solid liquid separation with better washing efficiency to increase recover y of metals. Clarifiion Polishes off residual solids from leached liquor for better performance of Copper SX plant.

Get Price -

Industrial: Powder Metallurgy

Typically, copper is melted and the liquid metal flows through an orifice where it is struck by a high velocity stream of gas or liquid, usually water, thus breaking the molten metal into particles which solidify rapidly. Particle size and shape are influenced particularly by the atomizing medium, the pressure and the flow rate.

Get Price -

Micro milling of pure copper | Request PDF

· In this study, the failure mechanism and factors which affect the micro end mill were studied during machining of pure copper workpiece. The machining operation were performed at various cutting...

Get Price -

CNC Machining Milling Process | Ardel Engineering

The CNC milling process can be broken up into four distinct stages: CAD model design: engineers create a 2D or 3D design of the desired part. CAD model conversion to a CNC program: the design is exported into a compatible file format and converted into machine instructions using CAM software. CNC milling machine setup: the machine operator ...

Get Price -

gold and copper milling process

copper milling process_Chemical Milling, Copper Etching, Photo chemical milling process is used for copper etching, aluminum, bronze, brass, nickel, steel, beryllium metal components and many other metals, NW Etch201. Inquire Now; Lead and Zinc US Department of Energy. Energy and Environmental Profile of the Mining Industry Lead and Zinc Ore Milling .

Get Price