-

Cement Grinding Plant For Sale

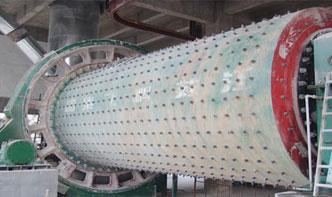

Available for dismantling january 2022 a very nice used cement grinding plant for 250 metric tons per hour. this plant features a polycom highpressure grinding roll (roller press), static separator, followed by a single chamber ball mill, shell supported, with combiflex drive, 5800kw; 2 cement coolers, all anciliaries. 50hz electrics. ...

Get Price -

Grinding Milling | Glen Mills, Inc.

Its versatility (cryogenic, wet and dry grinding at room temperature) makes the CryoMill the ideal grinder for quantities up to 20 ml. You may also be interested in the High Energy Ball Mill Emax, an entirely new type of mill for high energy input. ... Pilot Plant and Production machines for induction and dispersion of powders in liquids. The ...

Get Price -

Pet Bottles Grinding Washing Drying Plant in South Africa

If you are considering setting up a Pet Bottles Grinding Washing Drying Plant in South Africa, then we are the best help to get your endeavours accomplished. HK Industries is one of the major Pet Bottles Grinding Washing Drying Plant manufacturers in South Africa. We offer premium quality plastic recycling machines at phenomenal costs.

Get Price -

sJet ® 25 LaboratoryScaleSteam Jet Mill

The compactly constructed labplant includes all necessary components such as dosing, mill, product separation, control unit, fittings and steam generator on a skid. The space required for the assembly of the complete steam grinding plant is only 3 m 2, while the maximum necessary height is 2450 mm. All productcontacted parts as well as the ...

Get Price -

Grinding equipment mills | thyssenkrupp Mining Technologies

Grinding equipment from thyssenkrupp Mining Technologies is successfully in operation all around the world, grinding and drying gold ore, iron ore, iron ore concentrate, limestone, cement clinker, lime and coal as well as other mineral raw materials throughput capacities. Wet grinding in contrast involves the use of liquids/water to process the ...

Get Price -

Grinding technology

The different types of mills are designed for the dry and wet grinding of brittle and soft to very hard materials. The selection of the right grinding system has a big influence on the profitability of the entire process as well as on the quality of the product. We develop a concept for you which is suitable for your individual appliion.

Get Price -

Plant foods and different uses of grinding tools at the Neolithic .

Apr 27, 2020 · Furthermore, microwear analysis suggests that the drygrinding technique was adopted for cereal processing, and a piece of hide or animal skin was placed underneath the grinding slabs to gather the processed plant material. Apart from plant food processing, one of the grinding tools was also involved in processing bone.

Get Price -

How Is Cement Produced in Cement Plants | Cement Making .

Phase IV: Calcination. The calcination is the core phase of the cement making dry process. The calcination of the preheated raw meal takes place in the rotary kiln of the cement plant. The rotary kiln is a huge rotating furnace in which the raw meal is heated up to 1450 ⁰C and turned to clinker. The high temperature in the rotary kiln ...

Get Price -

Pellet feed grinding by HPGR

Mar 15, 2015 · Pellet feed material generally results from fine grinding to achieve a liberation size roughly between 20 μm and 150 μm. Following this, beneficiation is applied to generate concentrate grades of 65–69% Fe, by gravity separation, magnetic separation or flotation, or combinations thereof. One of the effects of the beneficiation generally is ...

Get Price -

Cryogenic Grinding

May 11, 2017 · Moreover, there is a possibility of adapting an existing coldgrinding system for an inert screening process. Thanks to the consistent further development and improvement of a previously inefficient process by NETZSCH Trockenmahltechnik , undesirable drying processes before screening in the area of cryogenic grinding are now a thing of the ...

Get Price -

Fives | Sustainable grinding with FCB Horomill®

Greener cement production with Fives' advanced grinding technology. The FCB Horomill® is our groundbreaking innovation in sustainable grinding. Its bedcompression grinding solution enables cement producers to vastly improve their grinding plant operation and product quality, while reaching sustainability targets. Download FCB Horomill ...

Get Price -

Cement Processing Line,Cement Grinding Plant,China Cement .

2500 Tons/Day Dry Process Cement PlantThe main process flow of this 2500t/d dry process cement plant is as follows: 1. Crushing, Conveying and Storing of Limestone. ... Cement Grinding PlantThe cement grinding plant mainly used in crushing and preheating of raw materials, and grinding and packaging of cement. And it is mainly applied to deal ...

Get Price -

Plastic Recycling Automatic Grinding Washing Drying Plant

HK Industries one of the most acclaimed Plastic Recycling Automatic Grinding Washing Drying Plant manufacturers in machine is designed to ensure proper cleaning of the plastic material before putting it into the molding process to ensure the better quality of recycled plastic items.

Get Price -

Abrasives Crusher,Abrasives Grinding Mill,Processing Machine Sale

Process flow is easy. Compared with tube mill, vertical mill has many advantages. High grinding efficiency; Reducing 2030% electricity consumption; Big drying ability; Material moisture abrasives can be 15%; Material insize is bigger; Degree of product fineness is easier to adjust; Chemical composition is steady. Abrasives Process Machine

Get Price -

Barite Grinding Plant | Schwob Energy Services

SES installed a large barite grinding plant in Larose, Louisiana for Baroid. This plant featured the construction of two dolphin piers with conveyors from raw material hoppers to the processing building. The project includes drying, crushing, and separation equipment with bulk storage tanks and a super sack station.

Get Price -

Grinding of soy with CW II and ZPS | Hosokawa Alpine

Contraplex CW II – a new dimension in grinding quality. The CW II model is the latest version of the tried and trusted design, which has been optimized specially to suit customer requirements. This machine is mainly used in grinding foods and in manufacturing polymer powder. Hosokawa Alpine optimized the Contraplex® CW wide chamber mill ...

Get Price -

MaxxMill

MaxxMill. Range of appliion. Continuous dry and wet grinding of coarsegrained materials to. fineground and ultrafineground products. Ground product separation. Dry grinding: Pneumatic extraction from the surface of the agitated media bed. Wet grinding: Separation of suspension from the agitated media by ball retaining device.

Get Price -

list of dry grinding cement plants in united states

Contribute to gcmcrusher/2022enposjx development by creating an account on GitHub.

Get Price -

Using Dry Grinding and Classifying for PlantBased Protein

How Size Reduction and Air Classifying Equipment Extracts Proteins. The most popular plant crops used for protein extraction are varieties of pulses and beans that contain between 2035% protein. Various extraction methods will concentrate this protein to 50% or better where more specialized techniques can isolate the protein to as high as 90%.

Get Price -

Grinding aid additives for dry fine grinding processes – Part II ...

Dec 01, 2021 · 1. Introduction. In various dry fine grinding appliions, socalled grinding aids (GAs) are added to the feed material or directly into the mill either to a) increase the production capacity, b) reduce the specific energy demand, which is required to obtain a certain product quality, or c) achieve finer material or a better performance of the later product.

Get Price -

Protein Shifting and Enrichment with the use of Dry Grinding .

May 19, 2020 · The beans or grains of a chosen crop are cleaned and dehulled, and afterward passed on for dry grinding, the objective of which is to break up the cells and to separate the starch granules from the proteins and fibrous cell parts. The most energyefficient method for achieving this, is impact grinding using the NETZSCH classifier mill type CSM.

Get Price -

Choosing the Right Grinding System for (Processing) Pigments

Mar 16, 2020 · The SJet is a jetmilling system, which has the advantages of drygrinding with superheated steam. It is used for ultrafine grinding of soft to extremely hard materials in a fluidised bed. By using an air classifier, integrated in the mill, the maximum particle size is limited and it is possible to achieve fineness in the submicron range.

Get Price