-

Dredged Sand And Gravel Processing | Modular Wash Plant

From the top deck a washed 'septic stone', + 1 ½", aggregate is sent to stockpile for future crushing and processing. The rinsed material between ¼" – 1 ½" from the midsize deck is fed to the AggreScrub™ 150 for scrubbing and removal of clay conglomerates.

Get Price -

Gradation Chart For Crushed Gravels

Gravel Crushing Contract Workshop Ndltap Natural sands and gravels are the product of weathering and the action of wind or water, while manufactured crushed fine aggregate and crushed stone coarse and fine aggregate are produced by crushing natural stone. Crushing, screening, and washing may be used to process aggregates from either sand and gravel .

Get Price -

Sand Gravel Washing | Washed Aggregates

We have become one of the Midwest's top aggregate producers and washing services by consistently providing our clients with the highest quality technology operated by experienced, professional team members. You can rely on us to provide you with the right equipment and expert crews to supply washed sand and gravel for your construction projects.

Get Price -

Washing Of Gravel In Crushing Plant

200Tph Wheel Type Sand Washing Plant Eastman Rock Crusher. Buckettype sand washing machine is an environmentally friendly sand washing equipment that can clean stone powder, bluestone, granite, weathered sand, gravel, pebbles, marble and other materials. buckettype sand washing machine has the advantages of high output and high cleaning degree. it is well .

Get Price -

How about Investing in a Sand and Gravel Factory?

Dust is mainly generated during the crushing, screening and transportation of sand and gravel aggregates. Dry dust removal or wet dust removal can be used, and the production line can be configured as semienclosed or fully enclosed to avoid dust pollution. 2. Noise control

Get Price -

Sand Gravel Washing | Washed Aggregates

Let's Chat. Aggregate washing is an extension of WD Scepaniak's custom crushing and screening services in the Midwest. Our clients utilize our sand and gravel washing technologies to produce construction materials that maximize their resource yield and minimize waste. We have become one of the Midwest's top aggregate producers and washing ...

Get Price -

Gravel, Rock Conveyor Belt in Quarry Plant | Quarrying

At Rayco, we provide heavyduty gravel and rock conveyor belts that ensure the best performance. It is superior to other reinforced belts in terms of toughness, durability and best wear life, and can be adapted to different conveying appliions in quarries. It can transport all kinds of hard rock and soft rock, metal and nonmetal minerals.

Get Price -

Aggregates Industry Equipment Manufacturer | Superior Industries

Using a combination of Superior's crushing, screening and washing equipment, Central Texas Stone Aggregate is producing some of the cleanest rock in Texas! See how they produce C33 concrete sand, #57 stone (3/4″) and pea gravel quickly and efficiently. Portability of Plants Matters in Rural Wisconsin

Get Price -

Crushing Tigers

Washing We provide heavyduty washing equipment to improve the quality of your finished product. Learn More... Material Handling We offer advanced, rational solutions for any material handling challenge, stationary or mobile. Learn More... Recycling Crushing Tigers Recycling equipment is engineered for maximum productivity.

Get Price -

Elite Crushing

We make big rocks small. Elite Crushing has been in business since 2009. We offer custom gravel crushing at your loion, or we can provide materials from one of our gravel pits. We specialize in gravel crushing and can provide various materials and services for construction projects, property development, agriculture, and more.

Get Price -

Custom Sand Gravel | Crushing Screening

Scepaniak is known for our custom aggregate crushing and screening services. We utilize over 60 pits across the United States to provide our clients with the best quality aggregates for construction. We configure our plants to ensure high production of spec material from unique quarry rock sizing to challenging asphalt aggregates.

Get Price -

Crushing Plant Capacity

· For gravel operations having little, or no, surge capacity ahead of the primary, a reserve crusher capacity of about 25 percent will usually suffice. Progressive gravel pit operators are awakening to the importance of providing a large surge pile at some point between the pit and the recrushing, screening, and washing section of the plant.

Get Price -

Setting up your wash operation for success

· Washing and classifying of aggregate can be considered in two parts, depending on the size range of material: 1. Coarse material. Generally above 3/8 in. (and sometimes split at 1/4 in. or #4 mesh). In the washing process, it usually is desired to remove foreign, objectionable material –including fine particles. 2. Fine aggregate.

Get Price -

Portable Screening/Washing Plants

Sand Gravel Sand and gravel are aggregates that are gathered from naturally occurring deposits. These aggregates, when gathered, may contain clays, silts and other deleterious material that needs to be processed out for commercialgrade products. Reduction and sizing can be accomplished with a variety of crushers and screens.

Get Price -

How Gravel Pits Work

· Finally, extraction can occur. Backhoes, frontend loaders, and bulldozers are all used to pull the gravel and sand from the pit. Before the extracted material can be sent off to the customer, it must undergo processing; this involves screening for large rocks, crushing, sorting, washing, and stockpiling the extracted material.

Get Price -

crushing how to crush gravel

Crush Gravel Please note for Crushed Gravel The following are all natural products and therefore variation in color and texture can occur We do not guarantee . 25mm Crushed Gravel BURNCO Landscape Products. 25mm 1 quot Crushed Gravel is a compaction material also known as 39 road crush 39 which is comprised of sand amp rock It is best used as a base .

Get Price -

STONE CRUSHING WITH HIGH EFFICIENCY AND LOWER COST

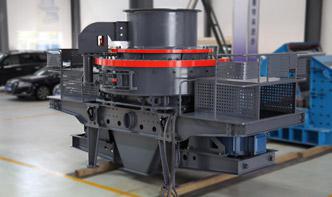

MOBILE CRUSHER. Mobile crusher is also called mobile crushing plant. It can be equipped with a feeder, a crushing unit, a conveyor belt, and a screening component. The combination of the units is flexible. All components are constructed on the body frame as a whole. Mobile crusher has advantages of great flexibility, easy loading and unloading ...

Get Price -

Crushing Wheel | Create Wiki | Fandom

Two Crushing Wheels must be placed next to each other horizontally or vertically one block apart. Both wheels must be given opposite rotational force. Any items to be crushed must be inserted where the wheels rotate inwards. Crushing Wheels will kill mob s and player s and eject their drops. Crushing

Get Price -

Baioni Crushing Plants – Crushing and Water Treatment Plants

Mobile crushing screening plants We design and manufacture modular system, portable solutions on tracks to be used in the primary, secondary, tertiary crushing of aggregates, in their screening and storage stages, whether they are materials from quarries, mines or recycling of construction waste and demolition.

Get Price -

Crushing / Screening

Sand and Gravel Washing Systems Polygonmach stationary screening and washing equipment is used for natural screening and washing of sand and gravel. Installations with different configurations can be designed according to the production capacity, the amount of final materials required a VIEW Vibrating / Grizzly / Prescreening Feeders

Get Price -

gravel crushing washing

PQ University Lesson 9 Washing Classifying : Pit Quarry Sep 10, 2015 Built primarily to wash crushed stone and gravel, coarse material screw washers effe

Get Price