-

Understanding Iron Ores and Mining of Iron Ore – IspatGuru

Apr 03, 2015 · blasting, crushing, Hematite, Iron ore, magnetite, open pit mining, screening, underground mining, Understanding Iron Ores and Mining of Iron Ore. Iron (Fe) is an abundant and a widely distributed element in the in the crust of the earth, constituting on an average ranging from 2 % to 3 % in sedimentary rocks to % in basalt and gabbro.

Get Price -

Iron ore price crushed again

· After hitting a high of in February, the industry was jolted on March 10, when iron ore suffered the worst oneday decline since the financial crisis, cratering % in a single ...

Get Price -

Fine Ore Storage Bin and Stock Pile

· The trajectory of the ore as it leaves the conveyor belt will determine where in the bin or pile each size of the crushed ore will land. Once in the bin, another stage of classifiion takes place. The smaller ore due to its lesser size and weight, tends to filter downwards faster than the coarse material does.

Get Price -

Iron Range 101: What is taconite? | Twin Cities Daily Planet

· The iron content, magnetite, is only 20 30% compared to 50 – 60 % iron content in red ore. Red ore is also referred to as direct shipped ore because it can be shipped without processing. Taconite needs to be crushed and processed into pellets before it .

Get Price -

Iron Ore and Pellets

But, before this, the ore goes through a blast furnace that only works when air can circulate freely. For this reason, the material needs to be big enough so that there are spaces between each piece. On top of this, the ore needs to be strong enough not to be crushed thereby obstructing the blast furnace.

Get Price -

How to Smelt Iron: The 6 Steps to Iron Smelting | The Crucible

Once broken into smaller pieces, the charcoal and iron ore (sand) are mixed together in a 1:1 ratio. 4. Charge the furnace Before adding the iron ore and charcoal mixture, the furnace must be charged. Charging a furnace simply means heating it up to .

Get Price -

iron ore crushing and screening plant capacity conveyor belt

Contribute to gcmcrusher/2022enposjx development by creating an account on GitHub.

Get Price -

Why are ores crushed before processing?

· Home Radiation Why are ores crushed before processing? In order to separate the minerals from gangue (the waste minerals), it is necessary to crush and grind the rock to unlock, or liberate, valuable minerals so that they are partially or fully exposed. This process of size reduction is called 12, 2018.

Get Price -

Pardoo mine

Iron ore mines in the Pilbara region. The mine commenced production in October 2008 and was the first producing mine to be operated by Atlas Iron. Ore is crushed and screened on site before being hauled by road trains to Port Hedland, where the ore is shipped from. [5]

Get Price -

Iron ore processing plant

Our iron ore processing plants can be retrofitted to your existing Raw Material Handling (RMH) system to facilitate the processing of mined iron ore before it is fed to the furnace. The processing of iron ore delivers significant efficiencies to your operations. Efficient Kiln Operation with clean Calibrated Lump Ore (CLO)

Get Price -

Iron Ore Pellets and Pelletization Process – IspatGuru

· Iron Ore Pellets and Pelletization Process. ... Undersized pellets are recycled back to the process, while the oversized pellets are crushed before their recycling. The rest is on sized (8 mm to 16 mm) pellets which are transported on a conveyor to the drying process in the segment of hot processes.

Get Price -

Iron Ore Crusher Price, Crushing Machine for Iron Ore Beneficiation

Crushing is a multistage process and may use dry iron ore feed. Typically, primary crushing andscreening take place at the mine site. Primary crushing is accomplished by using jaw crusher or gyratorycrushers. Primary crushing yields chunks of ore ranging in size from 6 to 10 inches. Oversize material is passed through additional secondary ...

Get Price -

Methods to Separate Metal From Ore

Sep 26, 2021 · Nearly all Earth's iron, however, exists in iron ore. Found away from the ground, raw ore is mixture of ore proper and loose earth known as gangue. The ore proper usually can be separated by crushing the raw ore and just washing away the lighter soil. Concentration of Ore. A Computer Science portal for geeks.

Get Price -

before the iron ore is crushed

Before Iron Ore Crushed. Challenges and opportunities in the iron ore crusher . Aug 08, 2019 The importance of iron ore crushing process Before dry selection, the lean iron ore requires millimeterscale fine crushing by the fine crusher If the particle size of the iron ore is not small enough in the crushing stage, lowgrade iron ore is difficult to be selected later, which will .

Get Price -

Mass, Weight, Density or Specific Gravity of Bulk Materials

As specific gravity is just a comparison, it can be applied across any units. The density of pure water is also lbs/ (pounds per cubic foot) and if we know that ammonium nitrate has a sg of then we can calculate that its density is x = lbs/ Note, kg/ divided by = lbs/

Get Price -

Extracting ores | Mining of mineral resources | Siyavula

Iron ore, a type of coal called coke (which contains 85% carbon) and lime are added to the top of the blast furnace. ... This meant that ore was crushed by jaw crushers before taken out of the mine. They also used the first trolleyassist system for haul trucks coming out of the pit.

Get Price -

11335 BHP Commodity Fact Sheets IRON ORE EX9

Iron ore undergoes a series of processes from pit to port before export. Finding the ore First, we explore the geology of the region to ˜ind the best ... for processing. Ore handling plant The crushed ore is then sorted over screens and resized to di˚erent speci˜iions, such as lump and ˜ines products. Stacker Once the iron ore is

Get Price -

Ore Sampling Methods: Good Proper

Feb 22, 2017 · a lot of ore crushed to cubes than in a lot crushed in 1in. cubes, therefore accuracy demands that the ratio between the weight of the largest particle and the entire lot shall increase directly as the fineness. In this particular, practice and theory are in complete accord, and all of the latest and most improved mills practice ...

Get Price -

Iron Ore Crushed Again as Burgeoning Supply Helps Bears Run Riot

· Iron ore's under the cosh. The commodity was beaten down again on Thursday in what's shaping up as a brutal month amid rising concerns that global supplies are poised to expand further while ...

Get Price -

Gold Extraction from Different Types of Ore

· The ancient placer gold ore is the petrified placer ore, which is composed of the petrolized gravel. The particle size of 80% ore is between 75100 microns. And this type of ore has a high grade. Gravity separation and cyanidation is a better process for gold extraction. Because it can recover more than 95% gold.

Get Price -

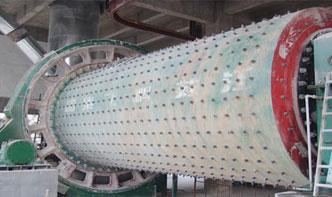

Iron Ore Crushing and Screening

The third processing in the iron ore crushing and sieving production line is sieving. Screening equipment generally use circular vibrating screen to sort the second crushing process to complete the material screening operations. Generally 10mm or less of the material can be selected after dry screening; 10 to 40mm material after sieving into ...

Get Price -

Iron ore crushed: Miners hammered

Jun 02, 2014 · The spot iron ore price was hammered on Friday, down 4% to US a tonne on Friday, the lowest price in 20 months, and a US80 something price is on the cards.

Get Price -

Iron Ore Crusher, Iron ore crushing machine, Iron ore crushing .

Iron ore crushing. The extracted iron ore will be transported to the primary crusher. Oversized and wet ore will be sent to the ROM stockpile for pretreatment before it is sent to the primary crusher. Primary and secondary crushing followed by screening will result in lumps and fines sized between 32mm +8mm and 8mm respectively. The lump ...

Get Price -

crushed iron calculator

Crushed Iron Ore needs to be further refined to Iron Concentrate before it can be smelted into an Iron Bar. Get a quote; BULK MATERIAL DENSITY TABLE Tapco, Inc. Iron Borings, Machine Shop 125 Iron Ore 100 200 Iron Ore, Concentrates .

Get Price