-

ball milling teqnique

Ball Milling Teqnique Ball Milling Techniques tvpdcollegein Jan 15 2015 14 Ball Milling Techniques Ball milling is a well understood process in which material that is used to grind How to Mill a Pocket or a Slot on the Vertical Milling Machine A simple approach to milling ball milling teqnique hospetsteels Ball mill Wikipedia A ball mill is a type of grinder used to grind .

Get Price -

What Is Ball Milling Glass Chips? Features Process

· A ball mill is simply filled with pebbles either of porcelain or stones and into it powder or slurry is added and mechanically rotated to cause the movement of pebbles in order to crush them into particles. Ball milling can be done periodically or can be continuous process.

Get Price -

ball milling technique

Highenergy ball milling technique for ZnO nanoparticles as. Apr 29, 2011 In this study, the highenergy ball milling (HEBM) technique was used to produce nanoparticles of ZnO from its microcrystalline powder.

Get Price -

ball milling teqnique

ZnO nanoparticles obtained by ball milling technique. The ZnO nanoparticles were obtained by ball milling of commercial grade ZnO powder at 250 rpm for 20 h and studied their structural, microstructure, optical and photoalytic properti Due to ball milling significant decrease in lattice parameters and average crystalline size is noticed for.

Get Price -

ball millling technique

ball millling technique ball milliron ore grindingball millling technique High energy ball milling process for nanomaterial synthesis What Is The Use Of Ball Milling ...

Get Price -

N‐Heterocyclic Carbene Acyl Anion Organoalysis by Ball‐Milling ...

· In summary, ballmilling has been used as a technique to conduct NHC alysis for the first time. A range of alysts, bases and grinding auxiliaries have been screened to reach general conditions for the acyl anion activation mode, which has been demonstrated in four appliion areas: intermolecularbenzoin, intramolecularbenzoin, intermolecularStetter and .

Get Price -

ball milling technique

Ball Milling Is A Technique; End mill Wikipedia. An end mill is a type of milling cutter, a cutting tool used in industrial milling appliions. It is distinguished from the drill bit in its appliion, geometry, and manufacture. Free Quote. Machinability Evaluation in .

Get Price -

Ball milling as a synthesis method

· Ball milling is generally known as a method to mix, blend, shape and reduce particle sizes. It can also be used as a mechanical synthesis method to produce materials that are milled to extremely fine powders.

Get Price -

ball millling technique

· dry ball milling technique wildpeppersf mechanical ball milling method and the bead milling technique to investigate the relation between the degradation of diffuse samples after finishing ball milling treatment were fully dried to remove ethanol at 110 C by dry oven Bead . live chat . Mechanical Milling a Top Down Approach for the. Synthesis of Nanomaterials and .

Get Price -

Use of Taguchi method for high energy ball milling of CaCO3 ...

· Taguchi's method was applied to investigate the effect of main high energy ball milling (HEBM) parameters: milling time (MT), ball to powder weight ratio (BPWR), and milling speed (MS) on the CaCO 3 crystallite size. The settings of HEBM parameters were determined by using the L9 (3 3) orthogonal experiments array (OA).

Get Price -

Pan‐Milling: Instituting an All‐Solid‐State Technique for .

· Among them, highenergy ballmilling is widely used in largescale preparation of metal oxide composites for lithiumion batteries (LIBs). However, ballmillinginduced highenergy mechanical activation may destroy crystalline structure, and thus the electrochemical activity of many metastable oxides such as anatase titanium dioxide (TiO 2 ).

Get Price -

SolventMinimized Synthesis of 4CzIPN and Related Organic .

· Employing sodium tertbutoxide as base, and negating the need for any air/moisturesensitive reaction setups, a selection of organic dyes was synthesized in just 1 h using this ballmilling technique. Furthermore, the transformation was then showcased on a multigram scale.

Get Price -

Top 5 productspecific milling technologies used in industrial ...

· A ball mill grinds material by rotating a cylinder filled with media (typically metallic or ceramic balls) mixed with a continuous flow of feed and recycled material. At slower rotational speeds, the grinding media creates a cascade motion where the media is mainly rolling and shear forces for grinding are generated.

Get Price -

Correction to: Ball milling as an important pretreatment technique .

· Furthermore, ball milling technique coupled with chemical and physicochemical pretreatments has been shown to facilitate lignin removal, reduce cellulose crystallinity, and increase the specific ...

Get Price -

Preparation of bismuth telluride based thermoelectric .

· LOWENERGY BALL MILLING AND THEIR PROPERTY CHARACTERIZATIONS A Thesis Submitted to the Faculty of Purdue University by Christopher A. Robinson In Partial Fulfillment of the Requirements for the Degree of Master of Science in Mechanical Engineering May 2015 Purdue University West Lafayette, Indiana ii ACKNOWLEDGEMENTS

Get Price -

BallMillingEnabled Reactivity of Manganese Metal

· previous reactions conducted under ballmilling conditions have shown that altering the liquid additive can alter the product selectivity or improve on reaction yields, therefore, alternative liquid additives were screened. 13 our results indie that more highly coordinating liquids induce the greatest reactivity, (table 1, entries 4 and 7), .

Get Price -

Direct Exploitation of the Ethynyl Moiety in Calcium Carbide .

· Sealed ball milling provides a novel way of activation of calcium carbide. No additive is required to transfer the acetylide moiety to organic molecules. Various ketones and even aryl halides can thereby be ethynylated. Abstract Ball milling of calcium carbide (CaC 2) enables the reaction of its ethynyl moiety with organic electrophiles.

Get Price -

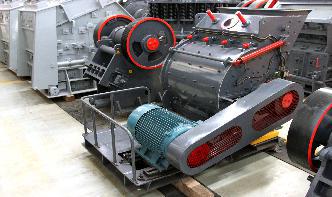

ball milling technique ball milling techniques

Jul 07 2017 Ball mill configuration. Ball mills use shear and impact milling techniques. Ball milling uses shear forces when particles are stressed between two surfaces that are moving in opposing directions. Particles experience impact forces as they fall against the media. A number of processing parameters influence the performance and ...

Get Price -

what is ball milling technique

Ball milling technique, using mechanical alloying and mechanical milling approaches were proposed to the word wide in the 8th decade of the last century for preparing a wide spectrum of powder materials and their alloys. In fact, ball milling process is not new and dates back to more than 150 years.

Get Price