-

What it is the optimun speed for a ball mill ?

· Calculation of optimum speed depends on knowing the media diameter and jar also. For instance, if your jar had in inside diameter of 90 mm and your milling media was mm diameter lead balls, the optimum rotation would be 98 RPM. Optimum RPM= .65 x Critical speed (cascading action of the media stops)

Get Price -

ball mill diameter 275mm

The mill used for this comparison is a 4 4meter diameter by 13 6 meter long ball mill with a fully autogeneous ball Get Price. diameter 6 meter ballmill bindassholidays. diameter 6 meter which type fanbelt require for 4 meter size ballmill. india cone type piercer mill Ball Mill.

Get Price -

Ball End Mills

Fraction ball end mills are available with shank diameters ranging from 1/8 to 1, and cut lengths ranging from 1/8 to 21/4. Metric ball end mills are offered in shank diameters ranging from 3 mm to 10 mm, and cut lengths ranging from to 40. Finishes available include TiAIN and .

Get Price -

Is a ball mill a kind of grinder used to grind materials into powder?

Balls commonly of size 50 mm dia, mostly made of hard metals like tungsten carbide, high carbon steel are present inside the ball mill mandrel to crush the material. There will be a closed mandral in which we add materials.

Get Price -

Large Diameter Cement Ball Mill, Continuous Ball Mill .

Large Diameter Cement Ball Mill, Continuous Ball Mill Manufacturer STRUCTURE This kind of ball mill consists of several parts including fillings entrance setup,main bearing,rotary part, gear cover and so on. The tube which equipped with antifriction sheathing board inside is welded of rolled steel plate.

Get Price -

Planetary Ball Mill PM 200

The Planetary Ball Mill PM 200 is a powerful benchtop model with 2 grinding stations for grinding jars with a nominal volume of 12 ml to 125 ml. ... Effective sun wheel diameter: 157 mm: Gforce: g: Type of grinding jars "comfort", optional areation covers, safety closure devices:

Get Price -

26788 Diameter Ball Mill

The apparent difference in capacities between grinding mills (listed as being the same size) is due to the fact that there is no uniform method of designating the size of a mill, for example: a 5′ x 5′ Ball Mill has a working diameter of 5′ inside the liners and has 20 per cent more capacity than all other ball mills designated as 5′ x ...

Get Price -

Polycorp

Polycorp Ball Mill Liners Ball Mill Liners We are regularly supplying rubber liners up to 26 ft diameter ball mills. We design liners to optimize power for maximum throughput and increased liner life. These liners are custom designed for your mills. Mining Ball Mill Liners PolyStl™ Liners

Get Price -

Tungsten Carbide Media Balls 3

310mm Diameter Tungsten Carbide Mill Balls In High Hardness Density For Metal Powder Grinding Overview Tungsten carbide mill ball is made of hard alloyed materials. It has advantages of high hardness, good abrasion resistance, anticorrosion, antibending and adaptable to tough working environment. Features

Get Price -

9/32 Inch Ball End Mills |

mill diameter (inch) 3/16 mill diameter (decimal inch) number of flutes 2 length of cut (inch) 9/32 length of cut (decimal inch) material solid carbide overall length (inch) 21/2 shank diameter (inch) 1/8 finish/coating uncoated single or double end single helix angle extended reach no material grade micrograin mill diameter .

Get Price -

Ball End Mills | McMasterCarr

Ball End Mills | McMasterCarr (630) Email Us Order History Clear All Cut Style Taper End Style Ball End System of Measurement Inch Metric Mill Diameter " " " " " " " " " 1/64" " " " " " " 1/32" " " " 3/64" " " 1/16" 5/64" 3/32" 7/64" 1/8" 9/64"

Get Price -

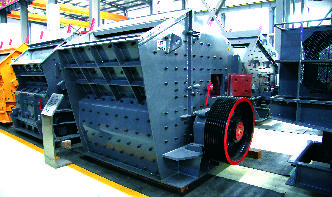

Ball Mill Ball Mill manufacturer, supplier

· The most common types of grinding equipment are ball mills. A BALL MILL grinds material by rotating a cylinder with steel grinding balls, creating the ball fall back into the cylinder and onto the material to be ground. Its rotation is depending upon the diameter of the ball mill and usually 4 to 20 revolutions per minute.

Get Price -

SIZE REDUCTION

At low speeds, the ball roll over each other and attrition (rubbing action) will be the predominate mode of action. Thus, in the ball mill, impact or attrition or both are responsible for the size reduction. Advantages: It can produce very fine powder. Ball mill is used for both wet and dry grinding processes.

Get Price -

Grinding balls, buy metal balls from Metinvest manufacturer

The main quality parameters of steel grinding balls manufactured according to DSTU 8538 are: rated diameter, nominal diameter, maximum deviations of diameter and hardness. The rated diameter is the diameter of the ball, rounded to the nearest values of the standard series.

Get Price -

question calculate the operating speed of the ball mill if the diameter .

May 15, 2015· 2) Ball milling – a ball mill with a diameter of meters, inside new liners, grinding wet in open circuit. When the grinding conditions differ from these specified conditions, efficiency factors (Rowland and Kjos, 1978) have to be used in conjunction with equation 1. Ball Mill Derivation To Calculate Critical Speed Of Ball Mill

Get Price -

Corehog

Find Ball End Mills; Mill Diameter (mm): ; Mill Diameter (Decimal Inch): ; Mill Diameter: ; Number of Flutes: 2 ; Length of Cut (Inch): 9/16 ; Length Of Cut: at MSC Industrial Supply, serving the metalworking, safety, and MRO industries for over 75 years

Get Price -

Ball Milling Glazes, Bodies, Engobes

The grinding action between the jar walls and balls is lost but the balls will still crush the particles between them if you mill for longer periods. Plastic mill jars also run much quieter. Typically small jars have a range of ball diameters from 14 cm. The pebbles cost about 6 US per pound and you need about 810 lbs for a 1 gallon jar.

Get Price -

Ball End Mills

Ball end mills, also known as "ball nose" end mills or fullradius end mills, have a constant single radius – or ball – at the end of the cutting nose radius is equal to half the diameter of the tool, and the edges are center cutting. The cutting profile has .

Get Price