-

Experimental Study on Limestone Cohesive Particle Model and Crushing ...

· We obtain the required particle impact velocity by adjusting the pressure. The impact velocity is calculated using a highspeed camera to measure the distance between points A and B and the time difference between the two frames. After collecting the crushed material, the size distribution is obtained.

Get Price -

Aggregate production: Fines generation during rock crushing

sections focus on the effect of crushing conditions on fines generation. 3. Single particle crushing Crushers break rocks by fracture propagation induced by the applied compression and shear forces. The theoretical bases for fracture mechanics started in 1921 when Griffith related fracture propagation to preexisting cracks or defects. Later ...

Get Price -

Poor choices place crushing contractors at risk

· The unit also boasts the innovative lifting tools system for changing the liners on the jaw crusher, saving more than half the time to replace liners. It also has 30% less hydraulic oil, making for considerable savings that the average customer would not expect. Pilot Crushtec has been the local distributor for for the past six years.

Get Price -

How many pounds of pressure does it take to break a bone?

The force needed to break a human femur is about 1700 PSI or over 1 million kilograms per square meter. For smaller bones, a pressure of 25 pounds may be enough to break them. The amount of pressure that it would take to break a bone depends on the bone. Some bones are stronger than others. Larry Isaacs

Get Price -

Enhanced Weathering: crushed rocks spread on farmland can ...

· Farming with crushed rocks One compelling aspect of enhanced weathering is that, in controlledenvironment studies involving basalt amendments of soil, cereal grain yields are improved by roughly 20%. As basalt weathers, it increases vital plant nutrients that can boost production and increase crops yields.

Get Price -

HSE

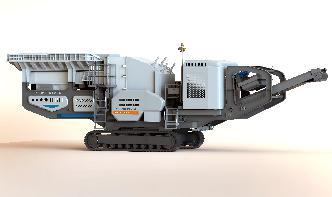

This guidance is for all those with responsibilities for the operation of mobile crushers, including contract managers, supervisory staff and operators of these machines. It covers the safe operation of the mobile crushing operation and includes guidance on clearing blocked crushers. This guidance cannot cover every risk and is not comprehensive.

Get Price -

A crushing victory

· Outside of gyratory crushing, Thyssenkrupp makes its mark with the Polycom HPGR, designed to save energy when compared to traditional AG and SAG mills. Thyssenkrupp's Polycom HGPR can achieve throughput rates of over 5000 tonnes per hour using around 40 to 50 per cent of the energy required by AG/SAG mills.

Get Price -

Small Rock Crusher for Sale, Mini Stone Crushing Machine Price .

It can crush kinds of ores and rocks with the hardness of medium and above medium. All around and considerate service is also provided to all the clients. Jaw crusher is mainly used for crushing various ores and large materials with compression strength not more than 320Mpa. Its fullyenclosed layout features high integration.

Get Price -

: The Rate of a Chemical Reaction

· The new reaction pathway provided by the alyst affects the energy required for reactant bonds to break, and product bonds to form. While many reactions in the laboratory can be increased by increasing the temperature, this is not possible for all of the reactions that occur in our bodies throughout our entire lives. In fact, the body needs to be maintained at a very .

Get Price -

Crushing and sizing technology for all stages

Crushing, sizing, milling, breaking technology for every appliion. Raw materials are so diverse. Even within a single mine or quarry you could be dealing with an extreme range: hard to soft, dry to sticky. Your crushing and sizing solutions need to be able to cope with whatever you throw at them – reliably, and in good time.

Get Price -

Mining council awarded 5M for rockcrushing tech

· The Canada Mining Innovation Council (CMIC) has received 5 million from the federal government to develop new rockcrushing technology that will reduce the amount of energy required in its use....

Get Price -

Mineral Processing

· Energy required for producing a specified reduction is proportional to the log of the reduction ratio. It is based on the assumption that geometrically similar particles would always break in geometrically similar manner, irrespective of the size. p f eck D D logfKE Kk = Kick's Constant and fc = crushing strength of the material

Get Price -

Crushing Equipment Supplies | Jaw Crusher, Impact Crusher, Cone .

The crushing method can be dry or wet. The gap between the grid section can be adjusted according to the client's requirement to get different grain sizes. box crusher The box crusher can directly crush materials with a side length of mm into powdered ores with a .

Get Price -

DESIGN OF MECHANICAL CRUSHING MACHINE

considering forces required for crushing and ergonomic factor that an operator needs. The design of this machine is such that it would require optimum load to crush metals and will not strain the user or operator. After the completion of design process, it is manufactured and transformed into a machine that would help in waste management. The crushing of used .

Get Price -

(Solved)

For efficient grinding, the energy applied to the material should exceed, by as small a margin as possible, the minimum energy needed to rupture the material . Excess energy is lost as heat and this loss should be kept as low as practicable.

Get Price -

Maximizing primary crushing productivity

· Importantly, the primary crushing process can continue with no break in production. A rock breaker also improves efficiency further along in the process because when the material flow from the primary station remains consistent, the following crushing stages produce better quality aggregates with a higher throughput.

Get Price -

Australian Crushing and Screening Equipment for Quarries and .

Crushing equipment for quarries and mines have crushers to break down large rocks and materials into smaller pieces, whether it be rocks, quartz, aggregate, gravel or sand. Significant force is applied to separate and break these materials, and this crushing equipment is typically used in a plant or material handling system.

Get Price -

Types of Rock Crushers | Quarry Crushing Equipment | Kemper

Typically, the minimum setting on most primary crushers will be about 4 to 6 inches, as noted above. Compressionstyle jaw, cone, impact crushers, and gyratory crushers are most often appropriate as primary crushing equipment types, though there can be overlap between primary and secondary crushers as far as suitable types. 2. Secondary Crushing.

Get Price -

Latest news from Invertek Drives | Extended product life and energy ...

· Extended product life and energy savings are being achieved in the demanding environment of industrial rock crushing thanks to the introduction of Invertek Drives Optidrive P2 variable frequency drive motor control. An Italian aggregate company was using a jaw crusher driven by a soft starter to break down river stones.

Get Price -

Chapter 8 BLAST DESIGN

amount of explosives required to break a unit measure of rock. Since rock is usually measured in pounds, there are several possible combinations that can express the powder factor. Powder Factor = Tons of rock (or cubic yards) per pounds of explosive. Normal range = 4 to 7 Shallow holes = 1 to 2 External loads = .3 Tons of Rock = Powder Factor lbs of Explosives The higher .

Get Price -

Estimates of Electricity Requirements for the Recovery of ...

Estimates of Electricity Requirements for the Recovery of Mineral Commodities, with Examples Applied to SubSaharan Africa . OpenFile Report 2011–1253. Department of the Interior . Geological Survey . Cover. High voltage power lines over the San Andreas Fault at Cajon Pass, California. Photograph by Don Becker, Geological Survey. Estimates of Electricity .

Get Price -

Jaw Crusher For Sale | Jaw Rock Crusher Supplies By Trusted .

At the same time, the material is crushed or split to achieve the purpose of crushing. When the jaw goes down, the angle between the toggle plate and the jaw decreases. Under the rod tension and spring action, the moving jaw plate leaves the fixed jaw plate. At this time, the crushed material is discharged from the mouth of the crushing chamber.

Get Price -

Investigation of Fundamental Mechanism of Crushing of Clods in .

In this study, we experimentally investigated the effects of compression and shear stresses on crushing a clod by using vibration and abrasion devices to make clear the sufficient forces for the crushing. We found that crushing occurred in our rodmill device at lower stress levels than the critical forces of the amorphous yield point.

Get Price