-

Integrated environmental assessment and pollution prevention .

· The production of anthracite in Vietnam is divided into two processes that are coal extraction and coal screening/preparation; transportation between the two stages is also included. The process of use or burning of coal is excluded as this study deals with the environmental assessment of coal production only.

Get Price -

(PDF) FINE COAL DRYING AND PLANT PROFITABILITY

· Abstract and Figures. This paper describes the increased plant revenue that can be achieved by coal preparation plants by using a suitable drying technology to significantly (by ~50%) lower the ...

Get Price -

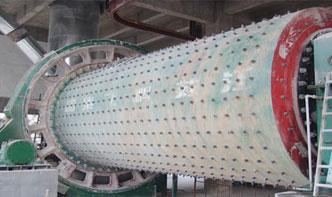

Coal Chemical Industry Rotary Dryer

Appliion: Widely used for drying all kinds of coal, lignite, carbon coal, including anthracite, lean coal and poor lean coal, lean coal, coking coal, fat coal, air fertilizer coal, gas coal, etc. dingliwyt (Wechat/WhatsApp) Send Email Price/Quote Introduction Parameter Case Strength Recommend Message

Get Price -

(PDF) FINE COAL DRYING AND PLANT PROFITABILITY

· computer simulation results indie that the overall plant yield of a typical coal preparation plant can be potentially increased by % if the moisture content of the clean coal product can be...

Get Price -

Vibratory Screening and Dewatering

The dry screening equipment featured below use high speed, low amplitude, and vertical elliptical motion to screen dry materials such as sand, iron powder, nickel powder, polyethylene pellets, coal, glass, and many other materials. These machines produce low amounts of sound and are fully enclosed for dust suppression. Lightweight screen panels and hinged and .

Get Price -

An Overview | PDF | Anthracite | Bituminous Coal

2 Anthracite Coals: ... The boiler uses particles of culm crushed to go through a mm screen. The culm is burnt in a fluidised bed, being stockpiled in tonne quantities prior to burner entry. The steam produced is at 90 bar, 513oC. The saturation temperature of steam 90 bar is, from steam tables, just over 300oC, so the extent of superheating is major. Also in Frackville is a .

Get Price -

high carbon low sulphur calcined anthracite coal

• Calcined Anthracite Coal Appliion: Calcined anthracite coal/gas calcined anthracite coal/carbon raiser is mainly used in steelmaking in electrical stove, screening water, shipbuilding sandblast to remove rust. It can reduce the cost of steelmaking effectively by replacing the traditional petroleum coke of carburant.

Get Price -

Standard Grade Coal

Anthracite Coal is very shiny, hard black coal, high carbon content and energy density, repels moisture, for domestic industrial uses, including smokeless fuel; Bituminous Coal is softer and shiny, moisture content is 8 20%, possible for coking coals, volatile matter from 16% 40%, can be used for thermal or metallurgical appliions; Subbituminous Coal is soft and black with .

Get Price -

COAL CHARACTERISTICS

ANTHRACITE COAL Anthracite: Sometimes also called "hard coal," anthracite forms from bituminous coal when great pressures developed in folded rock strata during the creation of mountain ranges. This occurs only in limited geographic areas –primarily the Appalachian region of Pennsylvania. Anthracite has the highest energy content of all coals is used for making .

Get Price -

Standard Grade Coal

Anthracite Coal is very shiny, hard black coal, high carbon content and energy density, repels moisture, for domestic industrial uses, including smokeless fuel Bituminous Coal is softer and shiny, moisture content is 8 20%, possible for coking coals, volatile matter from 16% 40%, can be used for thermal or metallurgical appliions

Get Price -

Adsorption Characteristics of Ionic Surfactants on Anthracite .

· The unit cell size of the anthracite model was × × nm 3 (x·y·z), and the model density was g/cm 3. For the parameter settings of the simulation, we refer to our previous work [ 28 ]. A surfactant–anthracite binary system and a water–surfactant–anthracite ternary system was constructed.

Get Price -

EMISSION FACTOR DOCUMENTATION FOR AP42 SECTION ANTHRACITE COAL .

anthracite coal firing is the singleretort sidedump stoker with stationary grates (see Figure 23). In this unit, coal is fed intermittently to the fuel bed by a ram. In very small units, the coal is fed co ntinuously by a screw. Feed coal is pushed through the retort and upwards towards the tuyere blocks. Air is supplied through the tuyere ...

Get Price -

Study of coal devolatilization and combustion under oxysteam ...

Coal reactivity in SteamTGA Anthracite Blend Proximate analysis Moisture (%, ) Ash (%, dry) Volatile (%, dry) Fixed Carbon (%, dry) Ultimate analysis C (wt.%, daf) H (wt.%, daf) N (wt.%, daf) S (wt.%, daf) Oa(wt.%, daf) LHV (MJ/kg, dry)

Get Price -

: anthracite coal

4996 of 105 results for "anthracite coal" RESULTS Price and other details may vary based on product size and colour. Keter Store it Out Nova Outdoor Garden Storage Shed, 32 x x cm, Dark Grey with Light Grey Lid 1,411 £14999 FREE Delivery by Amazon More buying choices £ (9 used new offers)

Get Price -

Coal Marketing International

Coal is hard and brittle and black and shiny, moisture content is 20 – 40%, calorific value 4,000 kcal/kg to 5,800 kcal/kg. Bituminous. Coal is softer and shiny, moisture content is 8 20% calorific value is 5,800 to 8,000 kcal/kg, crucible swelling number from 2 – 9+ possible for coking coals, volatile matter from 16% 40%. Anthracite.

Get Price -

Glossary

The heat content of anthracite coal consumed in the United States averages 25 million Btu per ton, on the asreceived basis (, containing both inherent moisture and mineral matter). Note: Since the 1980's, anthracite refuse or mine waste has been used for steam electric power generation. This fuel typically has a heat content of 15 million Btu per ton or less. Asreceived .

Get Price