-

Vibrating conveyors design overview

It should also be noted that alternative designs exist with a pan (also sometimes called tray) instead of a tube. The principle remains the same ; vibrating pan feeder design can reach higher throughput than tube design, they are also sometimes used in combination with a sieve to form a rectangular vibrating sifter. 2. Function in the process

Get Price -

How to Select a Vibration Isolator | LORD Corp

Another equation which is derived from the solution of the basic equation of motion for the undamped vibratory system is that for transmissibility – the amount of vibration transmitted to the isolated equipment through the mounting system depending on the characteristics of the system and the vibration environment.

Get Price -

Design Formula For Vibratory Feeder

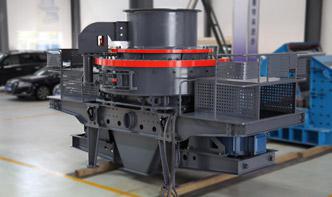

Design Formula For Vibratory Feeder T23:10:50+00:00. Wheel Sand Washing Machine. TSW Series Vibrating Feeder. CI5X Series Impact Crushers. ... GF series feeder. B Series VSI Crusher. Ball Mill. High Frequency Screen. European Hammer Mill. MB5X158 Pendulum Suspension Grinding Mill. Screw Sand Washing Machine.

Get Price -

Designing a Hopper

The most economical feeder is selected when the throat dimension T = x H,, T/H = As stated earlier, if T/H is outside the range of to, the material flow pattern is disturbed. This results in nonuniform flow. 5. When using an adjustable gate, it is desired to be parallel to the hopper's front wall.

Get Price -

Bowl Feeders | Vibratory Bowl Feeders | RNA Automation

Sizes range from 69mm diameter to 1200mm diameter, RNA represent a complete range of vibratory bowl feeders available from stock, including drive units, bowls, bowl centres, control boxes and additional accessories (stands, base plates, sound covers and sensors). Special requirements are available upon request.

Get Price -

Study on Vibratory Feeders: Calculation of Natural

if the bowl is rotated by an angle 6, the upper end of the leaf nomenclature b = width of leaf spring e = young's modulus /nl= natural frequency of fixed type vibratory feeder /„2= natural frequency of floating and semifloating type vibratory feeder g = shear modulus h = thickness of leaf spring /;. = geometrical moment of inertia j = inertia .

Get Price -

CHUTE DESIGN CONSIDERATIONS FOR FEEDING AND TRANSFER .

Without vibration (that is a = 0), h. b = m = 100 mm, a substantial amount. To reduce h. b. to say 10mm, an acceleration a = g is required. There are many combinations of frequency and amplitude to achieve this. For instance, a frequency of f = 151 Hz and amplitude of ... CHUTE DESIGN CONSIDERATIONS FOR FEEDING AND TRANSFER ...

Get Price -

Design Manual | HTRI

The Design Manual is the comprehensive reference for HTRI's thermal design recommendations for all types of heat exchangers. It summarizes calculation methods in HTRI software, provides design recommendations, and offers practical design tips. Topics covered include basic methods for singlephase pressure drop and heat transfer, condensation, boiling, twophase flow, .

Get Price -

Tutorial Selection of vibration isolators

By this equation, the natural frequency can be small, if one designs the equipment with very low stiffness and very heavy. But it is not a reasonable way. Instead of changing the design of the equipment, the natural frequency also can be decreased if a vibration isolation system is employed strategically to the equipment.

Get Price -

Vibrating Conveyors | General Kinematics

General Kinematics' Vibratory Conveyors have made their reputation in dependability, stability, and longevity. General Kinematics, a worldleading provider of vibratory equipment and design, began with aspirations of creating a better, more reliable vibrating conveyor that would stand up to the test of time in harsh environments.

Get Price -

2828 Clinton Avenue Vibratory Feeders

designing and building feeders to vibrate loads at a rate of up to 300 ton per hour DESIGN EXPERIENCE The Cleveland Vibrator Team has over 60 years of collective experience sizing and designing vibratory feeders for 100's of materials and appliions. So, you know you will get the right force, frequency, amplitude and custom

Get Price -

design formula vibratory feeder

Formula for rate of travel of material over vibrating feeder. 201634 4. the hopper designYES IT DOES MATTER 5 the friction created by the product at its various sizes agaisnt the hopper walls, the material itself, and the feeder itself numerous feeder typesYES IT .

Get Price -

Handbook for chain engineering Design and construction ...

this special design provides outstanding characteristics: highest resistance to wear and therefore prolonged service life breaking strength and fatigue strength remain high higher resistance to wear at increased temperatures improved surface finishes reduce fric tion properties and enable the chain to better handle deficient operational .

Get Price -

Vibratory Feeder Design Pdf

We can design and manufacture vibratory feeder bowls to sort out incorrect or bad parts from the feed system. Click Chat Now. Vibratory Scrap Feeder MHS. Think Outside the Design Evaluation Renovation Modifiion GILLESPIE + POWERS, INC. Complete with 48" wide at the through bottom, tapered to 72" wide .

Get Price -

Trap Design for Vibratory Bowl Feeders

· The vibratory bowl feeder is the oldest and still most common approach to the automated feeding (orienting) of industrial parts. ... Trap design for vibratory bowl feeders . IEEE International Conference on Robotics and Automation (ICRA), pp. 2558 –2563 . Google Scholar. Berretty, R.P., Goldberg, K. Y., Overmars, M. H., and van der Stappen ...

Get Price -

SCREEN CAPACITY CALCULATION

percentage of small feed material the greater the screen capacity. The faster the material passes through a screen the more open area there is left to screen the remaining material. A feed material with 40% of the feed being half the opening size or smaller equates to a factor of . Figure 6 uses the percent of feed material half the

Get Price -

Unified Practical Formulas for VibrationBased Method of .

· "Determination of the axial force on stay cables accounting for their bending stiffness and rotational end restraints by free vibration tests", Journal of Sound and Vibration, Vol. 317, No. 1–2, pp. 127 – 141. Google Scholar | Crossref

Get Price -

All About Vibrating Conveyors

2 days ago · These feeders are most useful for continuous weighing appliions where certain volume rates are needed and where other feeder types cannot be used. Besides the model above in Figure 5, vibratory feeders are also used in a bowl arrangement to convey oddly shaped small parts such as screws, rings, and more in an orderly fashion. They find ...

Get Price -

EXCITATION MODEL AND MOTION ANALYSIS OF THE VIBRATORY BOWL FEEDER .

The base of the proposed bowl feeder was made of structural steel (SS440), and the bowl was made of aluminum (Al2025). The main design parameters of the bowl feeder were as follows: mass of base was kg, leaf spring angle relative to horizon was 75o, mass of bowl was kg, angle of inclination was 2o.

Get Price -

design formula vibratory feeder

Design Formula For Vibratory Feeder. 24/12/2011 Design Formula For Vibratory Feeder. Study On Vibratory Feeders Calculation Of Natural. for design, development and practical use of bowltype feeders. 2. Equivalent Model of BowlType Vibratory Feeder The bowltype vibratory feeder is made up of four main parts, that is, bowl, springs, base and ...

Get Price -

vibratory feeders designs

Conveyor Dynamics | Vibratory Feeder Systems. Vibratory Feeders. Conveyor Dynamics manufactures vibratory feeders that range in size from 8 to 20 feet in length. These units can be equipped with a number of trough designs for feeding a wide variety of materials.

Get Price -

All About Vibrating Conveyors

2 days ago · Standard duty vibrating conveyors are built for medium to light density material, such as plastics, wood, porous rock, and the like. They are often rated with capacities ranging from 140 tons per hour at speeds up to 60 feet per minute and can be both modular and portable, depending upon needs.

Get Price