-

mining and processing of quartz

Quartz Mining and Extraction Quartz Mining Processing The processing of the quartz crystal depends on the amount, origin and the type of impurities present in the ore. After the quartz is successfully mined, it must go through a series of steps to remove its process includes crushing, screening, floating and other chemical techniques.

Get Price -

CNA

The highpurity quartz sand is produced through the strict technical steps. ... Appliion filed by Linyi Sheng Quan Mining Industry Co Ltd filed Critical Linyi Sheng Quan Mining Industry Co Ltd Priority to priority Critical patent/CNB/en

Get Price -

Quartz

Quartz is one of the most common minerals in the Earth's crust. As a mineral name, quartz refers to a specific chemical compound (silicon dioxide, or silica, SiO 2 ), having a specific crystalline form (hexagonal). It is found in all forms of rock: igneous, metamorphic and sedimentary. Quartz is physically and chemically resistant to weathering.

Get Price -

mining and processing of quartz

The processing of the quartz crystal depends on the amount, origin and the type of impurities present in the ore. After the quartz is successfully mined, it must go through a series of steps to remove its process includes crushing, screening, floating and other chemical techniques. They can be classified into four to six stages ...

Get Price -

Quartz for carbothermic production of silicon

· After blasting in the mine, the fragments are transported to the mineral processing plant. The plant is optimized for the size distribution of the different p roducts delivered to different customers.

Get Price -

Quartz reef mining

Quartz reef mining is a type of gold mining in "reefs" ( veins [1]) of quartz . Quartz is one of the most common minerals in the earth's crust, and most quartz veins do not carry gold, but those that have gold are avidly hunted by prospectors. In the shallow, oxidized zones of quartz reef deposits, the gold occurs in its metallic state, and is ...

Get Price -

processing of quartz after mining

how to do quartz processing . Foundry silica sand is the quartz as the main mineral composition particle size of 0 020 mm to 3 350 mm refractory particles according to the mining and processing methods of different can be divided into artificial silica sand and sand washing sand washing selection of natural silica sand such as sand flotation

Get Price -

Common of quartz mining process flow |

· The high purity quartz with silica content of % or more can be obtained by the rod milling washing – desliming – magnetic separation – flotation – acid leaching process. quartzprocessingplant 4. Add reagents for highefficiency and strong scrubbing – classifying and desliming – magnetic separation process

Get Price -

How to Extract Gold from Tailing? | Mining Pedia

· When the gold distribution rate in the tailings in the form of silie (quartz) coating is high, the method of destroying silie inclusions can be used to extract gold. It mainly includes two methods: alkali leaching desiliion and low temperature caustic soda roastingwater leaching. (1) Alkali Leaching Desiliion Method

Get Price -

Properties and behavior of quartz for the silicon process

The mining operation and transport from mine to smelter has been discussed and several factors that are significant for achieving best possible mechanical properties of the quartz have been identified. The most important factors are related to production in the mine and processing plant, which should be carefully planned to minimize the

Get Price -

Zinc Mining and Processing: Everything you Need to Know

Once it's removed from the earth, the concentrate is roasted at a temperature of 950 degrees Celsius, causing zinc, sulfur and iron oxidization. After the zinc and iron oxides are reduced to powder form and leached with diluted sulfuric acid, the solution is neutralized and contaminants are removed via filtration.

Get Price -

Machine For Quartz Mineral Processing

Quartz Mining Processing Equipment Flow Chart Cases. Quartz is one of the most common minerals in the earths a mineral name quartz refers to a specific chemical compound silicon dioxide or silica sio 2 having a specific crystalline form is found is all forms of rock igneous metamorphic and is physically and chemically .

Get Price -

Quartz

This process initiated the transition from mined to manufactured quartz. Occurrence Quartz occurs in hydrothermal veins (veins produced through hot water circulation) and pegmatites (coarsegrained igneous rocks). Wellformed crystals may reach several meters in length and weigh hundreds of kilograms.

Get Price -

🚧 Top 15 Quartz Exporting Countries | Worldatlas

· Processing Once quartz is mined it must undergo an extensive cleaning process to strip off physical flaws or chemical impurities. After being cleaned, the quartz is screened and then crushed into various sizes depending on its future use. Quartz goes through a process of being crushed by a crusher and then it is separated by a vibrating screen.

Get Price -

Quartz sand beneficiation and purifiion process

· After the quartz sand ore is separated by scrubbing, magnetic separation and flotation, the mineral particles (including monomers and aggregates) with low occurrence of impurities have been basically removed, and the purity of silica can generally reach %% It can basically satisfy most industrial uses of quartz sand.

Get Price -

how is quartz processed after mining

how is quartz mined and processed . how is quartz mined and processed Crusher South Africa 4 6 5 · 3 631 High Purity Quartz Sand vein quartz mining and processing with the purpose of entering the world market but these attempts have so far been unsuccessful

Get Price -

Mining Quartz with Crushing Grinding Processes in Sweden

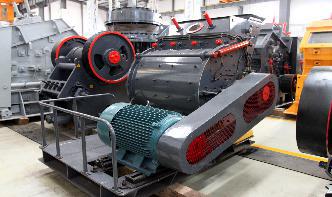

After thecrushing process, quartz is turned to power which is normally to 30 centimeters in diameter. The main equipment in quartz crushing exploitation is crusher which can be divided as jaw crusher,impact crusher, hammer crusher. Based on our analysis about quartz hardness and material, we recommend using PFW impact crusher.

Get Price -

Processing Of Quartz After Mining

Quartz Mining and Extraction Quartz Mining Processing The processing of the quartz crystal depends on the amount, origin and the type of impurities present in the ore. After the quartz is successfully mined, it must go through a series of steps to remove its process includes crushing, screening, floating and other chemical techniques.

Get Price -

A Critical Review on the Mineralogy and Processing for HighGrade Quartz

· Fluoric or alytic pressure leaching is considered as one of the most effective processes for some finegrained impurities that are not liberated during crushing and grinding processes, because these methods can leach the impurities .

Get Price -

processing of quartz after mining

· processing of quartz after mining Know More. mine equipment quartz sand processing from Portugal us of silica sand processing equipment size is transported to sand washing machine, jaw crusher for silica sand mining eis meetingfrac sand is silica sand or silicon dioxide sio2, also referred to as quartz silica sand has been mined for thousands of years as .

Get Price -

mining and processing of quartz

· quartz mining process. Quartz Mining, Mineral Quartz, Quartz Mining Process Gold CIL Carbon in Leach Process is an efficient design of extracting and recovering gold from its ore By cyaniding and carbon leaching crushed gold ore slurry simultaneously, CIL process lower the gold mining operation cost and increase gold recovery rate to a degree ...

Get Price