-

7 LAB TESTS ON AGGREGATE TO CHECK QUALITY FOR USE IN .

· The aggregate crushing value provides a relative measure of resistance to crushing under gradually applied crushing load. The test consists of subjecting the specimen of aggregate in standard mould to a compression test under standard load conditions (See Fig1).

Get Price -

Lab Test on Aggregates at Site

Aim of Aggregate Crushing Value To calculate aggregate Crushing value by testing aggregate passing mm sieve and retained on a 10 mm sieve. Scope of Aggregate Crushing Value This procedure covers all relative activity for the project site. Apparatus of Aggregate Crushing Value: 15cm dia. steel cylinder with plunger and base plate

Get Price -

Technical Note

Aggregate Crushing Value ... AS – Aggregates and rock for engineering purposes Part 7: Railway ballast AS 1141 – Methods for Sampling and Testing Aggregates AS – Methods of testing soils for engineering purposes Soil chemical tests ...

Get Price -

the purpose of aggregate crushing value test

AGGREGATE CRUSHING VALUE This test helps to determine the aggregate crushing value of coarse aggregates as per IS: 2386 (Part IV) – 1963. The apparatus used is Cylindrical measure and plunger, Compression testing machine, .

Get Price -

Aggregate Crushing Value Test Method

The purpose of this method is to determine the crushing value of the given sample of aggregate for the road construction works. The Principal mechanical properties required in road stones are: Satisfactory resistance to crushing under the roller during construction and Adequate resistance to surface abrasion under traffic.

Get Price -

Technical Note

Aggregate Crushing Value In addition to the limits specified in AS, the aggregate crushing value of the ballast material for Class H track when determined in accordance with AS, for the fraction of material passing the mm test sieve and retained on mm test sieve shall have a result no greater than 30%.

Get Price -

Aggregates: Sand, gravel and crushed rock aggregates for .

· In 1985, the Geological Society published Aggregates as the first volume in its Engineering Geology Special Publiion series. It met with immediate acclaim, being awarded the Brewis Trophy by SAGA in 1986. "If your work involves the use of aggregates, buy this book and read no further; this volume will be an essential and valuable reference that you will use .

Get Price -

Aggregate Crushing Value Test Wikipedia

AGGREGATE CRUSHING VALUE This test helps to determine the aggregate crushing value of coarse aggregates as per IS 2386 Part IV 1963. ... 8 Feb 2012 These crushing tests can reveal aggregate properties subject to per cent of the Aggregate Crushing Value and itcan be used for the same purpose.

Get Price -

What Are Aggregates and How Are They Used?

Crushed aggregates make up for around 60% to 75% of the volume of concrete. These crushed aggregates significantly affect the properties of freshlymixed and hardened concrete – making it more compact, decreasing its permeability (which makes it more waterresistant), and modifying its heat retention values.

Get Price -

the purpose of aggregate crushing value test

purpose of aggregate crushing value. The aggregate crushing value ACV of an aggregate is the mass of material, expressed as a percentage of the test sample which is crushed finer than a 2,36 mm sieve when a sample of aggregate passing the 13,2 mm and retained on the 9,50 mm sieve is subjected to crushing under a gradually applied compressive load of 400 kN 2 .

Get Price -

What Is Aggregate? Its Properties Uses – All About Engineering

Some of the purposes for which the aggregates being used are: As it is very cheap, so they are used as a filler to increase the volume of the concrete to reduce the overall cost of the construction. The use of strong and suitable concrete increases the strength durability of the structure. Its other use in concrete helps in the drainage of water

Get Price -

daØhV osQ fy, eksVs o eghu feykok fof'kfV

Crushed stone sand — Fine aggregate produced by crushing hard stone. Crushed gravel sand — Fine aggregate produced by crushing natural gravel. Mixed Sand — Fine aggregate produced by blending natural sand and crushed stone sand or crushed gravel sand in suitable proportions. Manufactured Fine Aggregate ...

Get Price -

Aggregates

Crushed aggregate is produced by crushing quarry rock, boulders, cobbles, or largesize gravel. Recycled concrete is a viable source of aggregate and has been satisfactorily used in granular subbases, soilcement, and in new concrete. After harvesting, aggregate is processed: crushed, screened, and washed to obtain proper cleanliness and gradation.

Get Price -

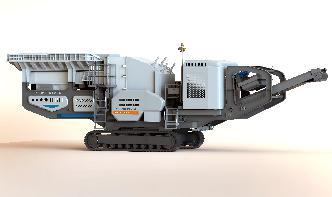

Crushers

Jaw crushers are mainly used as primary crushers to produce material that can be transported by belt conveyors to the next crushing stages. The crushing process takes place between a fixed jaw and a moving jaw. The moving jaw dies are mounted on a pitman that has a reciproing motion. The jaw dies must be replaced regularly due to wear.

Get Price -

the purpose of aggregate crushing value test

Scope Of Crushing Value Test On Aggregate S. the apparatus of the aggregate crushing value test as per is: 2386 (part iv) – 1963 consists of: 1) a 15cm diameter open ended steel cylinder with plunger and base plate, of the general form and dimensions as shown in fig 1.

Get Price -

New testing methodology for the quantifiion of rock .

· The main objective of this research is to quantify the crushability of hard rocks based on their mineralogical and mechanical properties. For this purpose, the mineralogical, physical, and mechanical properties of various hard rocks were determined. A new compressive crushing value (CCV) testing methodology was proposed.

Get Price