-

Grinding Circuit

There are such six parameters in our industrial grinding process which are αR, αB, βR, βB are the grindability indices and grindability exponents for the rod mill (R) and the ball mill (B); and γP, γS are the sharpness indices for the primary (PCSI) and secondary cyclones (SCSI).

Get Price -

Morila Gold Mine, Mali, West Africa

· The current method of gold production is the hydraulic processing of tailings. As the delivery of openpit ore to the mill begins in June 2021, gold production will rise from the current rate of 45,000oz a year to an average annual rate of approximately 160,000oz of gold, reaching a peak of 210,000oz a year through 2024 to 2025.

Get Price -

Equinox Gold

overview The current operation consists of the Piaba openpit mine and a conventional crushing and grinding circuit with an 8,000 tonnesperday carboninleach plant. The expansion will incorporate ore from the existing Piaba openpit deposit along with the Piaba underground deposit and the Tatajuba, Boa Esperança, and Genipapo openpit deposits.

Get Price -

Ore Processing | OceanaGold

Grinding and Sizing. Ore processing is a 24 hour operation. Ore is stockpiled at the processing plant, and the process begins by feeding the ore into a hopper with a loader. The ore is conveyed, and lime is added to raise its pH. Following crushing through a jaw crusher, the ore is fed into the semi autogenous grinding (SAG) mill along with ...

Get Price -

Grinding

Grinding operations are very powerhungry, which is another reason to avoid excessive grinding. Grinding circuit. The grinding circuit usually consists of a SAG or AG mill and one or two ball mills. Grinding is continuous and fully integrated with subsequent flotation operations. SAG or AG mills. The crushed products are ground in SAG or AG mills.

Get Price -

Overview

Overview Overview Côté Gold will be an openpit mine near Gogama, Ontario, in an established mining region with access to stable infrastructure and strong connections to local communities. To achieve consistent and efficient operations, we are implementing autonomous haul trucks and drills as the first pieces in our technological foundation.

Get Price -

crushing and grinding processing gold mine

Crushing and Grinding Wet amp Sticky Ore. ensp 0183 enspSolution to the Wet Ore Processing Problem A washing section is a must in all operations handling wet sticky ore This facilitates ore handling crushing and also affords a means for separation of primary slimes and increasing grinding capacity

Get Price -

Overview |Orezone Gold Corporation

The Company plans to develop the project in stages with Stage 1 focused on the Free Dig Oxides as a CIL operation with no crushing and minimal grinding with average recoveries of 87%. Stage 2 will focus on the underlying highergrade sulphides with a separate crushing and grinding circuit feeding the same CIL circuit as the oxides.

Get Price -

Are there differences in size distribution when comparing .

· The oxide ore is treated by acid leaching; consumption of acid is high and is managed by vat leaching rather than the more conventional heap leaching leaching process uses ore crushed to passing 8 mm to optimise copper recovery. Acid consumption generally increases with a higher proportion of fines.

Get Price -

Gold Recovery And How To Choose The Right Process

First, the material is screened to remove large rocks and boulders. Then a sluice or jig is used to recover the gold. For deposits with high clay content, the rocks are cleaned with a trommel or rotary scrubber to remove contaminants, and then gold recovery can take place. If a significant portion of the gold is fine (<300μm), a high Gforce ...

Get Price -

Major Mines Projects | Kolwezi Mine

Summary: On December 26th, 2018, the Phase II copper and cobalt project of Kolwezi copper mine started its trial production. Later on, the company continued to optimize the flow sheet and construction organization. Within 4 months, it got through all the production processes and produced the first batch of hode copper products, establishing ...

Get Price -

Major Mines Projects | Nevada Gold Mines Operation

Goldstrike consist of the BetzePost open pit and the Meikle and Rodeo underground mines. Meikle is a highgrade ore body which is mined by transverse longhole stoping, underhand drift and fill mining methods. Rodeo is a trackless operation, using two different underground mining methods: longhole open stoping and driftandfill. Cortez

Get Price -

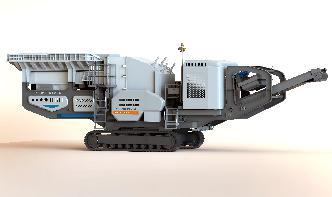

Crusher Machine, Crushing Equipment, Mining Crusher

Crusher is a common equipment used ac mineral processing plant for ores and mining. Email: liuyanan1103 ... In the mineral processing, ore crushing and grinding operations are essential material preparation operations ... 16:24:14. 1779. 3. HOT. 1. Summary of Gold Cyanidation Methods. . 5345. 996. 2. 6 Factors ...

Get Price -

Mineral Processing Part 1 | Geology for Investors

· Grinding reduces ore particles to micrometers in size. Mechanical screening is done during and after each crushing and grinding stage to control the particle size and separate material into grades. Depending on size compatibility with the next separation process, the material may require additional comminution cycles.

Get Price -

Ore Processing | OceanaGold

Ore processing is a 24 hour operation. Ore is stockpiled at the processing plant, and the process begins by feeding the ore into a hopper with a loader. The ore is conveyed, and lime is added to raise its pH. Following crushing through a jaw crusher, the ore is fed into the semi autogenous grinding (SAG) mill along with water and steel balls.

Get Price -

Overview

IAMGOLD is a midtier gold mining company operating in three regions globally: North America, South America, ... Process. Crushing; Grinding; Gravity concentration and intensive leaching; Ore leaching; Carboninpulp ... The Côté Gold processing plant will be highly automated with a 36,000tonneperday oreprocessing capacity.

Get Price -

Gold Mining and Processing: Everything you Need to Know

The Gold Mining Process. In addition to cyanide processing, gold ore is also processed with gravity separation. Advanced technology has enabled the amount of gold mined and processed to steadily increase over the years. For example, the worldwide production of gold in 2006 was 2360 metric tons. As of 2013, that number had climbed to 2770 metric ...

Get Price -

grinding gold raymond what is the chlorination process for gold mining

Energy and Environmental Profile of the US Department of Energy 71 Process Overview 711 Surface Mining Surface mining is the primary source of gold and silver It requires extensive blasting as well as rock, soil, and vegetation removal to reach load depositsGold Extraction From Silica Chlorination Gold extraction from silica chlorination gold chlorination process in jakarta .

Get Price -

Fosterville Gold Mine, Bendigo, Australia

· The processing plant includes crushing, grinding, flotation, bacterial oxidation, and carboninleach (CIL) circuits. The nominal capacity of the process plant is 2,275 tonnes per day (tpd). Its sulphide treatment plant is amongst leading BIOX systems in the world. The run of mine (ROM) ore is reclaimed from stockpiles and fed to a bin and blended.

Get Price -

Crushing And Grinding Processing Gold Mine

As gold ore's VHN hardness is between 60 and 105, TY design gold ore crushing plant and grinding of orere milling processing equipment mbmmllcbmmllcs gold ore milling and processing equipment is high performing by practicality, finances and permitting to a simple crushing and grinding circuit,et price old mining machines for sale in panama boyuk .

Get Price -

Processing

Total recovered gold: % Processing Flow Sheet 1. Crushing A fleet of autonomous haulers feed the primary and secondary crushers. A 54 x 75 primary gyrator crusher, which crushes ore at an average rate of 2,143 t/hr, was selected based on volumetric throughput and power requirement. 2. Coarse Ore Stockpile

Get Price -

Overview | Copper Mountain Mining Corporation

Mineral Reserves are reported using longterm copper, gold, and silver prices of /lb, 1,500/oz, and /oz, respectively. An average Copper Mountain Mine copper process recovery of 80%, gold process recovery of 65%, and silver process recovery of 70% is based on geometallurgical domains and actual plant values.

Get Price -

Superior Gold Inc. | Plutonic Gold Mine

Low lifeofmine (LOM) AllIn Sustaining Cost (AISC) of US863 per ounce gold. Technically simple project based on a pushback of the existing Plutonic Main Pit utilising existing processing and other existing infrastructure. Significant leverage to gold price: AUD265 million NPV5% at US2,000 per ounce.

Get Price -

Published Online August 2021 in IJEAST () OVERVIEW .

Main stages in ore processing are; Size reduction of ore material, crushing and grinding. Fig shows the processing steps in typical mining operations. Ore received from mine is brought from (a ...

Get Price