-

riley coal mills | Mining Quarry Plant

· riley pulverizer – CGM Mining Solution. Used Riley Atrita Coal Pulverizer Hammer Mill with Internal Classifier 31,: Jacobson Hammer Mill Model P160 10HP Hammermill With Good Hammers and ..

Get Price -

Coal Product | JE Trading Limited

Coal Product. Coal power is a rather simple process. In most coal fired power plants, lumps of coal are crushed into fine powder and are fed into a combustion unit where it is burned. Heat from the burning coal is used to generate steam that is used to spin one or more turbines to generate electricity. The concept of burning coal that has been ...

Get Price -

What Is Coal Power Plant and How Does it Work?

· A coalfired power station or coal power plant is a thermal power station that burns coal to generate electricity. A coalfired power station is a type of fossil fuel power station. The coal is usually pulverized and then burned in a pulverized coalfired boiler. The furnace heat converts boiler water to steam, which is then used to spin ...

Get Price -

UK vows to close all coal power plants by 2025

· The UK has committed to a programme that will phase coal out of all electricity generation by 2025. Canada has also said it will close its coal power stations by 2030, and both countries are ...

Get Price -

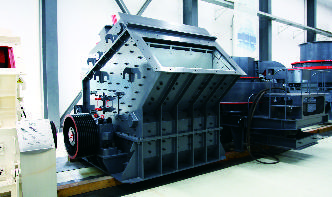

Multiphase flow simulation of a simplified coal pulveriser

· Coal pulveriser is a device used for separating large and small particles by relying, in general, on centrifugal forces to cause different size particles to follow different trajectories. By means of bowl rotation and due to centrifugal forces, the coal particles are moved away to clearance, where the pressurerollers crush them to fine powder.

Get Price -

Big changes at Cookstown

· Up until January 2022, the plant was operated as Lafarge Ireland by Aggregate Industries (AI), running the exLafarge cement plants in the UK, itself part of the Swiss multinational Holcim. Cookstown Cement Ltd bought Lafarge Ireland from AI on 21 January 2022 for Euro67m. The majority shareholder is LCC Group, which has an 80% share in the ...

Get Price -

Coal Handling Plant In Thermal Power Plant

Coal Handling Plant In Thermal Power Plant Consist of Following Process in sequence Unloading process This process involves unloading of coal from BOBR (Bogie Open Bottom Discharge) and Box type of BOBR wagons done in Track Hopper and for BOX types wagons unloading of coal is achieved by Wagon Tippler. Feeding Process

Get Price -

HF4 Coal Injection Plant, Charleroi, Belgium » Urbex | Behind .

The Injection Charbon, or Pulverised Coal Injection (PCI) Plant at the HF4 Blast Furnace was a later addition to the CockerillSambre site, built around 1991. The traditional way of releasing molten iron from iron ore in a blast furnace is to burn coke in the blast furnace along with iron ore, while blasting hot air in to aid combustion.

Get Price -

Pulverizer Coal Mill Spares

Reliable coal pulverizer performance is essential for sustained fullload operation of todays power plants. An effective pulverizer must be capable of handling a wide variety of coals and accommodating load swings in utility boilers as large as 1,300 MW. BWs pulverizers, found at power stations throughout the world. Kappatipulverizers COAL NOZZLE.

Get Price -

Britain could keep coalfired power plants open this winter

· LONDON, May 30 (Reuters) Some of the British coalfired power plants slated for closure this year might need to stay open to ensure electricity supply this winter, the government said on Monday ...

Get Price -

coal pulveriser machines mfg

Nov 11, 2013· coal pulveriser plant uk Coal crushing machine and grinding mill for processing plant ... Coal crushing machine pakistancrushers /aggre... Coal powder grinding equipments pakistancrushers /caol... Zenith pany provide ... pulverizer manufacturers india, coal pulverizer spare parts, ball ... 1 4 inch crushed rock, appl; 1 9 rock ...

Get Price -

COAL GENERATION IN GREAT BRITAIN

UK's legallybinding commitments. Coal power stations emit around twice the carbon dioxide of a modern gas fired power station. One of the biggest contributions we can make to reducing power sector emissions is to replace coal power stations with lowercarbon alternatives. Setting a clear end date for unabated coal generation will send a clear signal to investors in new generation .

Get Price -

Southwestern Corporation

Today, Southwestern services over 50 major electric power companies in North America and over 250 plants worldwide including Canada, Australia, and South Africa. Southwestern's primary business is the design, manufacture and servicing of performance modifiions and upgrades for coal pulverizers. Our work force is experienced and familiar with ...

Get Price -

A Comparison of Three Types of Coal Pulverizers

the pulverized coal from the pulverizer section through the coal pipes to the burners. A typical arrangement of an ATRITA pulverizer system is shown in Figure 3. AT RITA pulverizers can be designed for either pressurized or nonpressurized (suction) operation.. Vertical Roller Mill The vertical roller mill (VRM) shown in Figure 4 is an air swept, mediumspeed, vertical pulverizer .

Get Price -

COAL MILL PULVERIZER IN THERMAL POWER PLANTS

in pulverizer In coal pulverization, 5–20% of the material being crushed is abrasive mineral. Coal is not abrasive by itself. The minerals in coal that are the most abrasive are quartz and pyrite, which cause a abrasion or severe wear. carbides in the metal part, High chromium cast iron materials are used for improved abrasion ...

Get Price -

Home

RPM Associates, Inc has focused on providing innovative solutions for our industrial customers for 39+ years. We specialize in: Hardfacing Solutions of Wear Related Components Manufacture of WEARx Premium Plate Products Design Engineering Solutions Specialty Manufacturing Heavy Mechanical Services Pulverizer Mill Components OnSite Services

Get Price -

Process Of Coal Pulverizer In Rolling Mills Steel

Coal pulverizermill system one of the critical power plant components that is relied upon to convert the energy stored in coal into electricity is the coal pulverizer or coal flow is controlled by the feeder, allowing coal to flow into the pulverizer pulverized coal and air mixture is. Ball And Race Type Pulverizer

Get Price -

d laval mill leite en aracaju

Get Price. fine crusher babcock mill greencastproject . coal pulveriser plant uk YouTube. GET PRICE >> D Laval Mil Leite En Aracaju Musée Communal D'archéologie. D Laval Mil Leite En Aracaju 150 Views The Zenith is the professional mining equipments . ld kd d lu hj erdgm Read More. m boneham d stephen g rich j mills c Get Price + ww kodamjaya mil id . GET PRICE >> ...

Get Price -

Investigation of wear pattern in a complex coal pulveriser using CFD ...

· Coal pulverizers or mills grind largesized coal pieces (10–50 mm) to provide fine coal dust particles usually less than a micron up to several microns in size (with at least 70% by weight not exceeding 75 μm) for feed to combustion furnaces.

Get Price -

Coal Pulverizers Market

The Coal Pulverizer firstly grind coal into a fine powder, followed by drying and classifiion that plays key role to segregate fine particles of the crushed coal and further send them to the boiler. The fine particles are only allowed to pass through while coarse particles are recycled back for repeated pulverization.

Get Price -

HF4 Coal Injection Plant, Charleroi, Belgium » Urbex | Behind .

The air and coal mixture propagates through the iron ore during combustion. The technique had massive benefits to blast furnaces, as it is much more efficient and even allows cheaper coal to be used. The coal injection plant behind workshops and stores at the steel plant in Charleroi. By 2001 the site was becoming run down with a threat of ...

Get Price -

Coal Authority business plan 2022 to 2025

· By April 2025 we will: treat an additional 13 billion litres per year of mine water to prevent pollution of drinking water, rivers or the sea by 2025 – this is an increase of more than 10% on ...

Get Price -

Materials Industries

Since 1886, Bradley pendulum roller mills have been recognized as the best in class pulverizing solution for the mineral processing industry. Our mill systems range in output from 1 to 150 tons per hour with adjustable and uniform particle sizes from 50% passing 150 microns to passing 30 microns – all in a single pass.

Get Price