-

Improving Grind In A Ball Mill Pdf

This article borrows from Lloyd's research, which was obtained from the commercial ball milling industry, and explains some of the key design criteria for making your own ball in relation to the ball filling volume for quartz grind ing using two tumbling ball mills with different capacity. They proposed the following relationship for mill diame ter m 1 e 1 U .

Get Price -

How to Slash 5Axis Finishing Time | Modern Machine Shop

· The operation took 10 hours and 58 minutes. This video shows Accelerating Finishing dramatically reduced cycle time on this automotive pillar punch. For the Accelerated Finishing portion, a 12mm Emuge Taper Form endmill was used at 10,000 RPM, an 80 IPM feedrate and " stepovers. With this process 60% of the surface area was finished in ...

Get Price -

Methods Of Improving The Efficiency Of Ball Mill

· 1. Improvement of ball mill structure. At present, the focus of research is to improve the original equipment and develop highefficiency and energysaving ball mills, such as ceramic industry continuous ball mills, static and dynamic bearing ball mills, rolling bearing ball mills, central transmission energysaving ball mills, etc. these new ...

Get Price -

improving power consumption in ball mill

Mills usually operate in the range 65 82% of critical but values as high as 90% are sometimes used. A crucial parameter that defines the performance of a mill is the energy consumption. The power supplied to the mill is used primarily to lift the load (medium and charge). Additional power is required to keep the mill rotating. Power drawn by ball, semiautogenous and .

Get Price -

How to Improve Ball Mill Working Efficiency

· 2. Improve the grinding system of cement mill, improve the grinding efficiency. Improving the grinding efficiency, the most direct benefit is getting the finished powder maximum in time, reducing the rate of cement products back to the flour yield, decreasing the load of cement mill. 3. Add a high efficiency separator.

Get Price -

Mills Ball Mill To Improve

Tom s Tips Tricks #3. Plunge milling is a technique used to remove material quickly without generating a lot of heat It works particularly well for pockets with long end mills . Get Price. PDF Effect of circulating load and classifiion. The ball mill is the most common ore grinding technology today and probably more than 50% of the total world energy consumption for ore .

Get Price -

Tips/guides on making my own mini ball mill, using like a small .

So I'm in Thailand and can't easily get a toy rock tumbler to use, but supplies to make a ball mill is easy. I want a small ball mill though as I'll . Press J to jump to the feed.

Get Price -

5 Gold Extraction Methods to Improve Your Recovery Rate

· Since traditional ball milling equipment appears some shortcomings such as fast wear and large energy consumption, many manufacturers adopt new wearresisting rubber lining boards, sliding bearing to improve a mill operation efficiency and prolong a machine's service life. The gold ore grinding equipment in the grinding stage: ball mill,rod ...

Get Price -

3 simple ways to keep your mill at its best

· Step 1 – keep your mill clean. This may sound obvious – but a fundamental part of mill care is cleaning the mill – and this step is often neglected. If a mill is kept clean, then 'leaks and creaks' (such as grease leaking from bearing seals) will be identified earlier, cost less to repair, and fixed before major equipment failure.

Get Price -

Ten tricks for improving grinding efficiency of ball mill2

automatic casting grinding media ball molding line; tilting type pouring system; medium frequency induction furnace; balls separating and sorting machine; heat treatment equipment. electrical type heat treatment machine; gas type heat treatment machine; trolley type heat treatment machine; equipment for forging balls. automatic hot rolling ball ...

Get Price -

Improving Mill Shoe Bearing Reliability and Productivity

The minimum oil viscosity for most mills is 44 cSt at 100°C and typically requires an oil with an ISO 460 Cst viscosity. Lubricant Selection A mineral based gear or RO oil (and oil .

Get Price -

Improving energy efficiency in comminution

· SLW: Another example of improving wear life for increased mill performance, including reduced specific energy consumption, is given in a paper by Sever Ciutina ( MLS) and (Senior ...

Get Price -

Ways to improve the beneficiation yield of ball mill?

At the same time, the fineness of grinding also helps to improve the output of the ball mill. What are the effective ways to improve the ore dressing output of the ball mill? Generally speaking, there are three direct ways to increase the ore dressing yield: 1. The crusher is added before the mill; the fine crushing before grinding makes the particle size of the milled material greatly .

Get Price -

What's the Difference Between SAG Mill and Ball Mill

· The biggest characteristic of the sag mill is that the crushing ratio is large. The particle size of the materials to be ground is 300 ~ 400mm, sometimes even larger, and the minimum particle size of the materials to be discharged can reach mm. The calculation shows that the crushing ratio can reach 3000 ~ 4000, while the ball mill's ...

Get Price -

Ball milling

A ball mill is simply a container that is filled with pebbles (either of porcelain or stones Flint) into which a charge (powder or slurry) is put and that is then mechanically rotated to cause the tumbling pebbles to crush particles that happen between them. Ball mills can be continuous or periodic, they can be small or gigantic, low speed ...

Get Price -

Ten Tricks For Improving Grinding Efficiency Of Ball Mill2

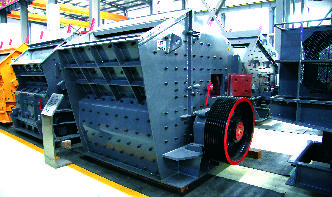

Ten Tricks For Improving Grinding Efficiency Of Ball Mill2. We are a professional mining machinery manufacturer, the main equipment including: jaw crusher, cone crusher and other sandstone equipment;Ball mill, flotation machine, concentrator and other beneficiation equipment; Powder Grinding Plant, rotary dryer, briquette machine, mining, metallurgy and .

Get Price -

Ball Mill From Mainly Recycled Parts : 11 Steps

1.) Turn the machine over and loe the screws on the bottom. (may be on side or back for different. models.) 2.) Take the screws out and unbolt the motor from the bottom panel and remove the panel. 3.) When the motor is loose follow all the wires to the motor and pull any plugs on the motor to be.

Get Price -

Could use some tips to improve my ball striking/distance

Here is 1 slow mo vid and another at normal speed of my swing: I am a 12 handicap and have some ball striking inconsistencies with my irons. Can . Press J to jump to the feed. Press question mark to learn the rest of the keyboard shortcuts. Log In Sign Up. User account menu. 3. Could use some tips to improve my ball striking/distance. Close. 3. Posted by 3 years ago. .

Get Price