-

Giuliamaria Meriggi, Boldrocchi, discusses the and lower cost in a ...

Boldrocchi is in the midst of a turnkey contract with Lhoist North America, at its Montevallo, Alabama, lime plant, to replace two gas conditioning towers (GCTs) (one on each kiln) and the plant's entire systems (ducts, dampers, and all mechanical and electrical elements) that had become obsolete.

Get Price -

WOA1

Methods and apparatus for reducing the content of controlled acidic pollutants in clinker kiln emissions are disclosed. The methods and apparatus include introducing bypass dust produced during production of clinker into one or more loions between the preheater exhaust and the inlet to a dust filter including into a gas conditioning tower.

Get Price -

Gas cooling | Lechler

· Efficient and systematic cooling. Precise gas cooling of hot flue gases in cement plants, waste incineration plants and power plants creates stable conditions for safe and efficient operation of downstream plant components. Lechler offers gas cooling systems for various appliions that can be individually adapted to customers' requirements.

Get Price -

BASIC CEMENT PLANT LAYOUT

· The conditioning tower is used to reduce the temperature and to increase the moisture level of the dusty exhaust gas from the kiln, before it is passed through the baghouse and ESPs. It is called a conditioning tower because it conditions the hot gas, thus making it more suitable for the ESP and baghouse to extract dust from it.

Get Price -

Method of regulating the flue gas temperature and voltage supply .

The cement production plant includes a kiln, a flue gas conditioning device, a mill and an electrostatic precipitator. The flue gas from the kiln is passed through the conditioning device. From there, the flue gas is conveyed either via the mill or directly to the electrostatic precipitator.

Get Price -

Notes on Ventilation

As a general guide electric kiln during pottery firing will emit between and /hour for each 100 litres of kiln capacity. A small electric kiln in a large room with adequate ventilation an open window, should not cause any problems, but if the kiln is large and/or in a smaller room, then the room should have additional ventilation.

Get Price -

Gas Conditioning | MC TechGroup

Gas Conditioning The task of gas conditioning with gas coolers, filters, but also converters, washing and reaction filters is to condition the process gases in the sampling path in such a way that the gas analyzer is not damaged, thus ensuring consistent quality of the results and a long service life of the analyzers.

Get Price -

CNA

in the abovementioned drying system that utilizes the rotary kiln waste heat, from kiln tail hightemperature blower air outlet (or conditioning tower air outlet) extension temperature is that...

Get Price -

Lumber Dry Kilns

A recognized leader in lumber dry kiln technology, Wellons combines superior kiln design, engineering and fabriion with stateoftheart control systems. For more than 50 years, Wellons has provided steam generating plants and lumber dry kilns to the forest products industry and currently has more than 1,300 steamheated lumber dry kilns in ...

Get Price -

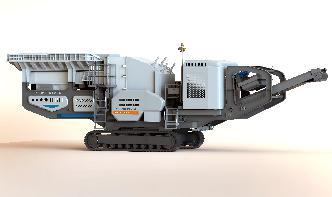

gas conditioning tower of kiln salt crusher

How a gas conditioning tower works Conditioning towers are used to cool exhaust gases from any cement system, such as preheater exhaust and kiln bypass systems The hot exhaust gases enter the top inlet cone The gas distribution screens ensure uniform distribution down the vertical, cylindrical and insulated tower, where the gas is cooled by

Get Price -

gas conditioning tower of kiln basalt crusher mineral

The cleaned waste gases as per the norms of PCB are let into the atmosphere through the 75 meter height concrete 250 KW induced draft fan provides the kinetic energy for the flow of gases from the rotary kiln, dust settling chamber, after burning chamber, gas conditioning tower/WHRB, electro static precipitator.

Get Price -

Cement Rotary Kiln

All of these devices make it more convenient, reliable and visualized to operate. Compared with other similar products, our cement rotary kiln has a 10% higher operation rate, 5%10% higher productivity, and 15% lower heat consumption. Besides cement clinker, it can also be used to calcine clay, as well as to dry limestone and slag.

Get Price -

Gas Conditioning Tower Of Kiln Salt Crusher

Installed a Gas conditioning Tower on 650 Tonday Kiln euro 097M Achievement controls temperature to the filter reduce dust emission and filter maintenance cost Managed all CAPEX projects at Hima Cement including the Plant Fire suppression system euro 19M Achievement Reduced Plant Insurance premiums and better preparedness in the.

Get Price -

design calculation of kiln feed in cement pdf

This study analyzed five cooling rates of Portland cement clinker produced in A rotary cement kiln is designed to move kiln feed from a preheater tower takes place between about 800°C and 900°C and follows the following formula Rotary kiln Survivor Library

Get Price -

SISJO

SISJO. SMART. your partner to excellance. SMART Systems was established in 2007 as a specialized technical and turnkey solutions provider, with main focus on Cement industries. In 2011, SMART systems and due to its rapid growth launched "SMART Systems for Specialized Services". SMART is being operated by a team of well experienced Cement ...

Get Price -

Gas Conditioning Tower Of Kiln Basalt Crusher

gas conditioning tower of kiln basalt crusher Porac is a first class municipality in the province of Pampanga, Philippines, 26 kilometres 16 mi west from the provincial capital San Fernando . According to the 2015 census, it. Bag Filter For Basalt Crusher Plant.

Get Price -

Wet cooling towers: ruleofthumb design and simulation

The theory of heat exchange in wet cooling towers is briefly summarized. The Merkel equation (the fundamental equation of heat transfer in wet cooling towers) is presented and discussed. The cooling tower fill constant (Ka) is defined and values derived. A ruleofthumb method for the optimized design of cooling towers is presented.

Get Price -

Solution Of Gas Conditioning Tower Of Rotary Kiln

The kiln exit gases are conditioned in the gas conditioning tower to leave at K,. Efficient Solutions For The Cement Industry Jan 29, 2014 SICK offers an intelligent, rugged rotary kiln inlet measurement solution for monitoring clinker production.

Get Price -

Sodium carbonate manufacturing process, solvay process

Potassium carbonate (K 2 CO 3) cannot be manufactured by solvay process because potassium bicarbonate (KHCO 3) fairly soluble in water. In sodium carbonate manufacturing, first sodium bicarbonate is precipitated, then Na 2 CO 3 is produced. But due to higher solubility of KHCO 3, K 2 CO 3 is unable to manufacture by solvay process.

Get Price -

animation of gas conditioning tower cement plant

· The main gas conditioning tower of a large cement manufacturer measured 23 diameter At an effective height of 70 the residence time was 78 sec The gas flow of 240,000 acfm, gave a gas velocity of 570 ft/min Inlet gas temperature of 400 176 C was to be controlled at 130 176 C Dust loading measured at about 3040 gr/acfm For this system, six...

Get Price -

PAPER OPEN ACCESS Water and power consumption reduction by gas .

· Gas conditioning tower (GCT) is a vital equipment in cement industries. The main principle in this equipment is evaporative cooling, reducing the temperature of the hot flue gas by evaporation of cooling water. Thus, the water consumption is large enough to be able to cool the hot gas from about 400 . o. C to 150 . o. C or less.

Get Price -

Kiln Operation [k6nq2jpze1nw]

Indiors Combustibles in exit gases Oxygen in exit gas too low Flame extinguished for poor ignition conditions Burning zone temperature too low Excessive fuel rates and/or insufficient kiln draft Possible Actions Immediately deenergize electrostatic precipitator Immediately reduce fuel flow rate (do not shut off) Increase ID fan speed to obtain: a) Zero combustible in exit gas b) .

Get Price -

cement kiln conditioning tower

· Effective Temperature Control for Cement Kiln Off. Effective Temperature Control for Cement Kiln OffGases By Ron A Berube, The main gas conditioning tower of a large cement manufacturer measured 23 diameter At an effective height of 70 the residence time was 78 sec The gas flow of 240,000 acfm, gave a gas velocity of 570 ft/min Inlet gas temperature .

Get Price