-

coal utilization

Coke ovens Modern coke ovens can be as large as metres (21 feet) high, metres (50 feet) long, and metre ( feet) wide, each oven holding up to about 36 tons of coal. The coking time (, between charging and discharging) is about 15 hours. Such ovens are arranged in batteries, containing up to 100 ovens each.

Get Price -

crushing coal crushing equipment coke oven plant

Coal crushing the different grain size distribution of the raw coal is cause by the different structural strength, methods of mining and processing. this effects the requirements for the coal handling system of the coke oven plant. the main equipment for this process is the crusher station. normally it is equipped with hammer mills.

Get Price -

coal crushing production line video videos

Coal crushing amp; processing. coal has widely appliion, mainly used for combustion, coking, gasifiion, low temperature distillation, hydrogenation liquefaction. 1. combustion. coal is an important energy resources, any kind of coal can be used as industrial and dom.

Get Price -

Selecting efficient coal crushing technology for coking processes ...

Made available by Department of Energy Office of Scientific and Technical Information ...

Get Price -

Training

The course is presented by experts recognized in the field of coal quality, for both thermal and coking coals, who offer practical advice on best practice for the management of coal quality and its usage. The 4day Coal Quality course, presenting an indepth examination of: Sampling, Preparation Coal Analysis

Get Price -

Suppliers coking coal

Petro Chemical Supplying Company is a global Group based in Turkey which manufacturers and provides chemical and raw material in different cases with deep industrial products are mainly Petroleum coke, Coal, Bitumen, Sodium Hypo 15 %16 %, Whalnut shell, Sulfuric geranuler99/98 DYM RESOURCES Germany

Get Price -

Coke (fuel)

Coke is a grey, hard, and porous coalbased fuel with a high carbon content and few impurities, made by heating coal or oil in the absence of air—a destructive distillation process. It is an important industrial product, used mainly in iron ore smelting, but also as a fuel in stoves and forges when air pollution is a concern.. The unqualified term "coke" usually refers to the .

Get Price -

crushing of coking coal

Oct 23 coal to be utilised during commissioning of the Crushing coking coal project areas Berenice/Cygnus and Somerville/Donkin that together . Rational Crushing of Coal Charge for Improvement. Grade composition and properties of coal charge are primary factors defining physicmechanical properties of coke Variation of charge makeup under conditions . coking .

Get Price -

COKING COAL

What is Coking Coal? Coking coal is the building block of society. It is used to produce coke which is a porous solid composed mainly of carbon and ash, and is produced when the coal is heated to drive off volatile matter. Good quality coke is hard, has a high crushing strength and is mainly used in blast furnaces that produce iron.

Get Price -

Specifiions Guide

· AsiaPacific And Atlantic Thermal Coal Loions 5 US Thermal Coal Assessments 9 US Physical Thermal Coal Netbacks 11 US FOB assessment inputs 11 Forward Curve Assessments 14 Petroleum Coke Assessments 15 Petcoke Loion 15 Clean Dark Spreads 17 Spot Dry Bulk Freight Assessments published in Coal Trader International 19 Metallurgical .

Get Price -

Calcite mining and processing plant

Thus, the selective fine crushing of high coking pressure coal is a promising way to reduce coking pressure and prolong coke oven life. Discover the world's research 20+ million members. Coking Wikipedia. Coking is the heating of coal in the absence of oxygen to a temperature above 600 °C to drive off the volatile components of the raw coal, leaving a hard, strong, .

Get Price -

coking plant

It takes about 18 hours to convert 35 tonnes of coal into 25 tonnes of metallurgical coke. The coke cake is unloaded from the oven by a pusher machine, which is equipped with a pusher arm. A cokeguide car guides the coke into the quenching car. The coke is then transferred to the coke quenching tower, where it is quenched with water.

Get Price -

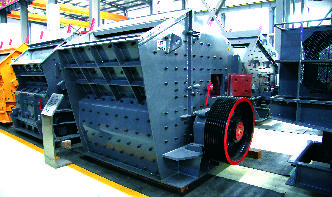

types jaw crusher used for crushing hard coking

Coal Crusher Types Impact Double Roller Crusher. Coal crusher, also known as double stage crusher, is a highly efficient crushing equipment. It is a new type of equipment developed for the coal industry, and it mainly crushes high moisture coal. Besides, it is mainly used to crush coal cinder, slag, shale, coal gangue and other materials. get ...

Get Price -

Crushing nests | Old School RuneScape Wiki | Fandom

To crush a nest, use a pestle and mortar on it. It will slowly grind the nests one by one, so the speed can be significantly increased by crushing each nest manually. Doing this may be easier by placing the pestle and mortar next to the last nest in your inventory, reducing the distance you need to move your mouse.

Get Price -

various types of coal mill coking coal production equipment

Fill in first and second item to compare. ... Major miners'' coking coal production takes a hit in FY22, guidance for next fiscal lowered. 22 Jul, 19:06 IST ... Classifiion of grades across various price channels. Hubungi kami. Coke oven coking process introduction. · The raw coke oven gas generated in the high temperature carbonization process rises up to the .

Get Price -

Selection of Coal for inclusion in Coal Blend in Coke Making

· For soft coking coal the limit of Gray king value is G min. Mean Maximum Reflectance (MMR) – The value of MMR in coking coals vary in the range of % – %. Soft coking coals have lower MMR while hard coking coals have higher MMR. Vitrinite – The value of vitrinite in coking coals is 50 % minimum. For soft coking coals the limit is 45 %.

Get Price -

Calcite mining and processing plant

Therefore, the fine crushing of coal in order to reduce coking pressure has not been positively used on a commercial scale. Ratio of coking coal and iron ore to make steel. Ratio of coking coal and iron ore to make steel Products. As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction .

Get Price -

types of pulveriser burner | Mining Quarry Plant

· Types of Coal Pulverizers,Ball Mills,Impact Mill,Vertical .. Coal pulverizer appliion. Pulverization is currently the favored method of preparing coal for burning. Mechanically pulverizing coal into a fine powder enables it .. Category: Unegorized. « micropulveriser instrument of bhaisjya kalpna. ball mill 3 compartments tirax ».

Get Price -

Crushing Of Coking Coal

Coking Coal Has A Branding Problem By Doomberg. Nov 02, 2021 Coking coal is used along with iron ore to make steel. If the world cannot produce steel, much of the world economy grinds to a halt. Unfortunately for coking coal, it has coal in its name. Unfortunately for the renewable power industry, they're going to need a lot of coking coal ...

Get Price -

Jefferies Coal Crusher | Crusher Mills, Cone Crusher, Jaw Crushers

Derailed train buries Ellicott City in coal, crushing two teen s Peabody Energy's fourthquarter profits soar Oct. 21, 2010 — A haul truck loaded with coal heads to the crushing hopper at Peabody's . of the heavy rains and other supply disruptions in Australia," Jefferies . Phillip Wilson – New Zealand | LinkedIn

Get Price -

Coking Coal | PDF

RAW COAL CRUSHING O SIZING U CLEANING C T Pencucian dan benefisiasi Batubara untuk : Memisahkan material pengotor Mengurangi kadar Abu,P dan S Meningkatkan Nilai Kalori Mengendalikan Ash fusibility Memperbaiki sifatsifat batubara untuk dibuat Kokas DEWATERING WASHED COAL fPeralatan Pencucian / Benefisiasi Batubara

Get Price -

Crushing Of Coking Coal

Coking pressure control by selective crushing of high,sep 15, 2011 against this backdrop, we investigated the selective fine crushing of high coking pressure coal as a way to reduce coking pressure. It was shown on a laboratory scale that the fine crushing of high coking pressure coal increases the permeability of the plastic coal layer, which decreases coking pressure

Get Price