-

Brickies Sand: Why and Where Should You Use It

· The use of brickies sand extends to building construction as it can also be utilised in sporting arenas, agriculture, fields, and most other projects that require sand with medium clay content. Brickies sand is primarily used in appliions such as: Wall construction Limestone block work Sand joints Roof capping Different types of brickies sand

Get Price -

Construction Sand and Gravel Statistics and Information

Construction sand and gravel, one of the most accessible natural resources and a major basic raw material, is used mostly by the construction industry. Despite the low unit value of its basic products, the construction sand and gravel industry is a major contributor to and an indior of the economic wellbeing of the Nation.

Get Price -

Oil Sands Extraction and Processing

Insitu Production Insitu extraction methods are used to recover bitumen that lies too deep beneath the surface for mining (greater than 75 metres underground). Currently, 80% of oil sands reserves are accessible via insitu techniques. Steam Assisted Gravity Drainage (SAGD) is currently the most widely used insitu recovery method.

Get Price -

COARSE SAND | Kuert

Coarse Sand is used with aggregate, water, and cement in the production of readymix concrete. Coarse Sand is ideal for bedding pipes and septic systems, as a base material for concrete slabs or concrete pavers, traction sand for roads and sidewalks, and mixing with topsoil and mulch to create a top dressing material for planting lawns.

Get Price -

Oil Sands Mining | Alberta Energy Regulator

Total Water Use. In 2020, just over one billion cubic metres (m 3) of water was used to produce about 604 million barrels of oil equivalent (BOE) from oil sands mining, down from 2019 production of 630 million BOE (see the following figure). This decrease in oil sands production is the first since 2016 (2016 production was million BOE less than the 2015 level).

Get Price -

Sands – Target Products Ltd.

This plant complements our existing industrial sand plant in Morinville AB, 20 km north of Edmonton, which produces many specialty sand products for the abrasive, filtration, golf, traction and other dedied industries. For further information please contact mrogan or info Logistics

Get Price -

Sand Washing Waste Recycling Wet Processing Solutions | CDE

Material Quarry Waste, Limestone, Crushed Rock, Sand Gravel, Manufactured Sands Output 2 Sands | 3 Aggregates End Use Construction Products, Concrete Production 200tph wash plant processes limestone to produce manufactured sand and three washed aggregates. VIEW CASE STUDY Whitemoss Construction England Tonnage 100tph

Get Price -

Oil Sands Extraction and Processing

Large shovels scoop the oil sand into trucks which then move it to crushers where the large clumps of earth are processed. Once the oil sand is crushed, hot water is added so it can be pumped to the extraction plant. At the extraction plant more hot water is added to this mixture of sand, clay, bitumen, and water in a large separation vessel ...

Get Price -

Sand Control

Sand Control Dedied downhole equipment and services Migration of sand within the reservoir can present major obstacles to well production through reduced production rates, sand bridging, erosion of equipment, and sand disposal and removal. Our sand control services begin with an indepth analysis of the reservoir and well conditions.

Get Price -

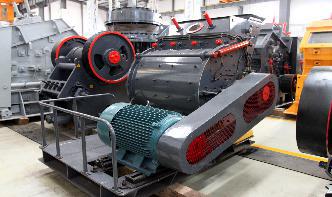

Sand Casting For Manufacture

Usually sand used to manufacture a mold for the casting process is held together by a mixture of water and clay. A typical mixture by volume could be 89% sand, 4% water, 7% clay. Control of all aspects of the properties of sand is crucial when manufacturing parts by sand casting, therefore a sand laboratory is usually attached to the foundry.

Get Price -

Sand control techniques

· The maintenance and workover method is primarily used where there is: Minimal sand production Low production rates Economically viable well service Rate restriction Restricting the well's flow rate to a level that reduces sand production is a method used occasionally.

Get Price -

Land Use

In the visualization we see the breakdown of global land area today. 10% of the world is covered by glaciers, and a further 19% is barren land – deserts, dry salt flats, beaches, sand dunes, and exposed rocks. 1 This leaves what we call 'habitable land'. Half of .

Get Price -

Sand casting

Sand casting, also known as sand molded casting, is a metal casting process characterized by using sand as the mold material. The term "sand casting" can also refer to an object produced via the sand casting process. Sand castings are produced in specialized factories called foundries.

Get Price -

Types of Sand: Uses, Properties, Grain size Classifiion.

Followings are the classifiion of Sand: Based on the grain size of the particle, sand is classified as Fine Sand ( to ), Medium Sand ( to 2mm), and Coarse Sand ( mm to ) Based on origin, sand is classified as Pit sand, River sand, Sea sand, and manufactured sand.

Get Price -

Sand Washing Plant | AggreSand 206 | Washing Systems

The Aggresand 206 integrated sand washing plant is readily portable and particularly suitable for greenfield appliions, contractor user and temporary planning permission sites. Operators more used to static installations will still appreciate the small footprint and minimal site preparations required for this washing plant.

Get Price -

22 Uses of Sand

Industrial sand is used to make glass, as foundry sand and as abrasive sand. One creative usage of sand is serving as a candle holder. We can try putting some sand before pouring tea light or any candle in a glass. It holds the candle still and refrain the candle from rolling by giving it an excellent decoration.

Get Price -

Recycled sand and plastic waste are used to make this sustainable brick ...

· The project started with a goal of producing zero waste from the sand reclamation plant in the Rhino Machines foundry plant. There were many experiments before landing on this ratio, initially foundry dust was used in cementbonded fly ash bricks (710% waste recycled) and clay bricks (15% waste recycled). This production process was reliant on ...

Get Price -

The Green Sand Process :: Vulcan Engineering Co.

The additive used depends on the metal cast. The sand is blended in a mullor or mixer, where the water and the additives are blended with the sand. The sand is then ready to be used to make a mold. There are several methods of molding but all methods squeeze or compact the sand against a pattern to make an impression of the part to be cast. The ...

Get Price