-

How To Calculate The Primary Drive For Ball Mill

How To Estimate The Wear Rate For Ball Mill Page 1 Of 10. Dec 08, 2009 Re how to estimate the wear rate for Ball mill. Most practical way to by measuring empty height and calculating the volumetric filling of grinding way to make track of mill main drive kW consumption reduction and add makeup charge according to the extent of fall in power .

Get Price -

FLOW CALCULATOR

FIRST CHOOSE WHAT YOU ARE SOLVING FOR. In this case we are solving for TIME so click on that button. Enter 9 in the "volume" box and choose cubic yards from the menu. Enter 80 in the "rate" box and choose cubic feet per minute from the menu. Click the CALCULATE button and your answer will be seconds OR minutes OR hours.

Get Price -

Mechanochemical Bromination of Naphthalene Catalyzed by .

· A mixture of 1 (100 mg, mmol) DBDMH (– equiv.), and zeolite CBV760 (50 mg) was milled at 30 Hz for 2 h using a 14 mL Teflon milling jar and one ZrO 2 milling ball ( g). After the milling was stopped, the reaction mixture was dissolved in a minimal amount of ethyl acetate and the zeolite was recovered by centrifugation.

Get Price -

Milling Finish: Complete Guide [ Tips, Techniques, and Secrets ]

A smaller ball interpolated exposes more of the surface to a faster moving cutter, leading to a better finish. But, the smaller cutter can flex more. Hence the need to balance these two factors. If you have a 4th axis or 5axis mill, you can try "Sturz" milling to combat the slow moving tip. See below for details.

Get Price -

Mechanisms: Lead Screws And Ball Screws | Hackaday

· Ball screws are a different beast. They look similar to lead screws — a threaded rod with a nut — but function completely differently. Where the lead screw thread profile is generally ...

Get Price -

Our modern vertical roller mill takes you further

The OK™ Mill is offered in a complete size range, including 3, 4 and 6roller mills, and the largest vertical roller mill size available with installed power over 11 500 kilowatts. This ensures the ability to meet all possible capacity requirements in a single vertical roller mill solution. Reliable largesized mills help reduce the project CAPEX investment and the total cost of .

Get Price -

drive calculation of 3 ton ball mill arrangement in ceramic plant ...

Drive Calculation Of Ton Ball Mill Arrangement In Drive calculation of 3 ton ball mill arrangement in drive calculation for a ball mill uk Xinhai service personals are experienced professionals in mineral processing You only need to call us, and the rest is our work Get More Details; Ball Mill Wikipediadrive calculation of ton ball mill arrangement in drive calculation .

Get Price -

Modeling of particle size and energetic requirement in amaranth .

A planetary PM100 ball mill (Retsch, Haan Mettman, Germany) equipped with a cylindrical stainlesssteel jar (500mL) was used. The samples of amaranth (154g) and stainlesssteel balls (φ=10 mm) in a relation of (1:5) were placed inside the cylindrical jar filling it to a third of its capacity. The grinding was carried out as a function of time and speed of rotation. To analyze .

Get Price -

Thermal Stability of Medium and HighEntropy Alloys of 3dTransition ...

· ascast al x cocrfeni alloys commonly consist of fcc dendrites and a bcc interdendritic phase, depending on the al content: only the fcc phase was obtained for x =, a fcc + bcc mixture for x =, and bcc alone for x = [ 8, 9] at temperatures above 873 k, the ascast equiatomic alcocrfeni bcc phase transforms into fcc, with .

Get Price -

Volume Calculator

Considering the use of length and diameter mentioned above, the formula for calculating the volume of a tube is shown below: volume = π. d 12 d 22. 4. l. where d1 is the outer diameter, d2 is the inner diameter, and l is the length of the tube. .

Get Price -

to calculate ball mill drive hp

Page 1 Ball Milling Theory. With most ball mill designs, you have two areas of speed reduction to tweak from the motor drive shaft to the drive pulley and from the roller bar to the milling jar The drive train calculator featured on this page gives you a...

Get Price -

Halogen bonding as a supramolecular dynamics alyst

· A series of linear transit calculations have been performed, altering the H–C–C–C dihedral angle from −180° to 90°, in steps of °, for the methyl group closest to the halogen bond donor. The...

Get Price -

Ball Mill Calculation Equipment Equations Principle

Working principle of ball mill with line diagram opening the ball mill box reveals a users manual a mill base two mill jars and five extra drive belts unpacking the ball mill the ball mill jars the first thing that struck me when i first looked at these mills was the nice quality of the mill discuss the types of ball mill, the basic principles of the ball mill, how it works, the ...

Get Price -

Microstructure and mechanical properties of aluminium .

· Ball milling. The powder mixture of Al alloy and vol.% GNSs was milled in a planetary ball mill, which was carried out in a 500 ml stainless steel jar. The confined powders were firstly ball milled at 180 rpm for h for premixing, and then at 250 rpm for the following 20 h under argon atmosphere. Samples were taken out at 2, 5, 10, 15 ...

Get Price -

High Energy Ball Mills Instead of Planetary Ball Mills

The Emax is an entirely new type of ball mill for high energy milling. The unique combination of high friction and impact results in extremely fine particles within a very short process time. The high energy input is a result of the extreme speed of 2000 min1 and the optimized jar design. Thanks to the revolutionary cooling system with water ...

Get Price -

UC Berkeley Previously Published Works

2S by ballmilling at 450 rpm in a zirconia jar with zirconia milling media. We tried three molar ratios for CrCl 3:Na 2S—1:2 (stoichiometric), 1: (% Na 2S excess), and 1: (25% Na 2S excess)—producing NaCrS 2 and NaCl (eqn (3)). In the second step, the ballmilled mixture of NaCrS 2 and NaCl were placed in a carbon crucible ...

Get Price -

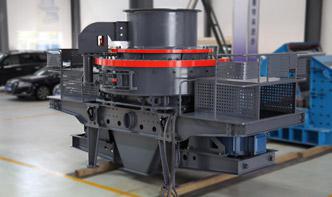

Ball Mill

Ball mills give a controlled final grind and produce flotation feed of a uniform size. Ball mills tumble iron or steel balls with the ore. The balls are initially 5–10 cm diameter but gradually wear away as grinding of the ore proceeds. The feed to ball mills (dry basis) is .

Get Price -

Coal Grinding

As a rule of thumb, the residue on 90micron sieve should not be less than half of the volatile content for safety purpose. ie. R90>=1/2. Volatile Content %. Coal Moisture: The degree of drying, and therefore the required mill outlet temperature (from 6580 0 .

Get Price -

Laboratory Mills

Ball mills normally operate with an approximate ball charge of 30%. Ball mills are characterized by their smaller (comparatively) diameter and longer length, and often have a length to times the diameter. The feed is at one end of the cylinder and the discharge is at the other.

Get Price -

Ball mill pinion | prmdrive

· Pinion module of ball mill: Module is the ratio of pitch t to PI (m = t/ PI) between the teeth of the same side of two adjacent gears, measured in millimeters. Modulus is one of the most basic parameters in gear manufacturing. The larger the modulus is, the higher the tooth is, the thicker the tooth is. National standard ball mill pinion module ...

Get Price -

How to Size and Select Ball Screws: An Engineer's Guide

· There are several techniques for preloading. Some common methods include oversizing the balls inside the nut housing; using the socalled "doublenut" or "tension nut" method; or by using a manufactured offset in the raceway spiral to change the angle of ball engagement (the "lead shift" method) and deliberately force the balls ...

Get Price -

Quick and Easy Black Powder Ball Mill — Skylighter, Inc.

· Putting a mill jar on the unit, plugging it in, and flipping the switch on, reveals that in its current configuration, the mill turns the jar at about 60 revolutions per minute (RPM). With the motor compartment open, the wiring exposed, and the pulleys and drive belt visible, too, please be careful when plugging the unit in and turning it on. 00:00

Get Price