-

Detailed Diagram Of Grinding Process In Gold Mining

Detailed Flow Diagram Cement Grinding Mill. Mar 17, 2017 Grinding Circuit Process Control Variables The importance of the grinding circuit to overall production in any facility should be obvious by now. Because of the responsibilities assigned to grinding it becomes essential that a grinding mill accepts a certain required tonnage of ore per day while yielding a product that is .

Get Price -

Limestone Handling System Flow Diagram With Grinding Mill

Home Limestone Handling System Flow Diagram With Grinding Mill. Copper Ore Processing Equipment. Capacity: (m ³/min) Suitable Materials:Copper, zinc, lead, nickel, gold and other nonferrous metals, ferrous and nonmetal. View Details Send Enquiry Ceramsite Production Line. Production Capacity:705,000 t/d Raw Materials:Clay, mudstone, slate, gangue, coal ash, .

Get Price -

Home

link to Knuckle Joint – Parts, Diagram, Design Calcuation, Appliions. Knuckle Joint – Parts, Diagram, Design Calcuation, Appliions. Knuckle Joint A knuckle joint is used to connect two rods which are under the action of tensile loads. However, if the joint is guided, the rods may support a compressive load. A knuckle joint... View Post. link to Plastic Material – Types, .

Get Price -

Cement Manufacturing Process: What is Cement made of.

Flow Diagram of Dry Method of Manufacturing of Cement. (i) Preparation of Slurry: In Wet Process, raw materials are supplied to the kiln in the form of an intimate mixture with a lot of water in it. This is called SLURRY. To obtain the SLURRY of a standard composition, the raw materials are first crushed separately using crushers for limestones and grinding mills (wet) for clays. .

Get Price -

detailed diagram of grinding process in gold mining

These processes are discussed in more detail below 2 Generalized Process Flow Diagram Gravity Separation Gravity separation relies on density differences to separate desired materials from host rock Devices used include gold pans sluices shaking tables and jigs Gravity separation is used at most placer mines and nbsp . iron mining wet grinding process description. iron .

Get Price -

Jewelry Manufacturing Process | Marcasite Silver Jewellery ...

Our jewelry model can come into life with the use of two computeraided manufacturing (CAM) methods: CNC mills and 3D printers. CNC milling machines carve a jewelry model from a block of wax and use sharp rotating tools or cutters to remove all parts that are not needed. Milling is a subtractive method in contrast to additive manufacturing as in 3D . For the 3D .

Get Price -

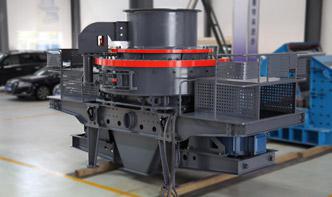

14 Types of Grinding Machines [Working, Diagram PDF]

· Centreless grinder. Surface grinder. Universal grinder. Tools and cutting grinder. 1. Bench Grinder. These types of grinding machines are fixed on a workbench or table. Gear or pulley is fitted in it. For rotating the bigsize gears or pulley a handle is also fixed.

Get Price -

Commercial rice milling systems

Description of flow of materials and processes 1 – paddy is dumped in the intake pit feeding the precleaner A – straw, chaff and empty grains are removed 2 – precleaned paddy moves to the rubber roll husker: B – husk removed by the aspirator 3 – mixture of brown rice and unhusked paddy moves to the separator

Get Price -

Spinning Process

· In this machine process various levels are added to convert fiber (cotton/wool) into yarn to process it further for textile products. This transformation goes through various levels such as: Step 1: Blowroom process. Step 2: Carding. Step 3: Combining. Step 4: Drawing. Step 5: Roving. Step 6: Cone winding.

Get Price -

Mahlkönig | Electric premium coffee grinders for coffee shops and .

A true allround home grinder with stepless grind size adjustment from espresso to French Press, grind by time presets and reduced noise for ultraquiet grinding. The 54mm special steel burrs, designed and manufactured in the Hamburg factory like Mahlkönig's professional grinders, ensure an even particle size for an incredible taste experience.

Get Price -

RICE MILLING

Flow diagram of a modern rice mill The flow diagram below represents the configuration and flow in a typical modern rice mill. 1 paddy is dumped in the intake pit feeding the precleaner 2 precleaned paddy moves to the rubber roll husker: 3 mixture of brown rice and unhusked paddy moves to the separator 4 unhusked paddy is separated and returned to the rubber roll husker .

Get Price -

Mineral Processing

A complete flow diagram, including crushing, grinding, density media separation, froth flotation, and pyrometallurgical and hydrometallurgical process route to achieve the highest purity of metals. PGE, platinumgroup elements. Sign in to download fullsize image Figure

Get Price -

Detailed Project Reports

Detailed Project Reports The detailed project reports cover all the aspects of business, from analysing the market, confirming availability of various necessities such as plant machinery, raw materials to forecasting the financial requirements. The scope of the report includes assessing market potential, negotiating with collaborators,

Get Price -

SHIMADZU CORPORATION

· Since 1875, Shimadzu is pursuing leadingedge science and technologies in analytical and measuring instruments including chromatographs and mass spectrometers, medical devices, aeronautics, and industrial equipment.

Get Price -

What is the Flow Chart of Wheat Milling to Flour

The flowchart contains a number of aspects for milling of wheat and displays issues such as storage and blending bins, as well as separator screens. As long as you follow what is displayed in the flow chart, the milling process will be quite simple. Purifiers, sifters and scourers are just but a few of the items which are displayed on the wheat ...

Get Price -

Coal mill pulverizer in thermal power plants

· The rolls do not touch the grinding ring even when the mill is empty. 16. of CE Bowl Mills 17. Mill Grinding rolls 18. for 500 MW 1. TYPE XRP 1003 OF MILL 10 T/HR – 525 KW 600 RPM 19. 13. Mill Performance Criteria FINENESS, COAL GRINDABILITY, CAPACITY, .

Get Price -

Processes of Waste Water Treatment: 4 Process (With Diagram)

This article throws light upon the four processes of waste water treatment. The four processes are: (1) Preliminary Treatment (2) Primary Treatment (3) Secondary or Biological Treatment and (4) Tertiary or Advanced Treatment. 1. Preliminary Treatment: . As already stated, preliminary treatment involves the removal of floating materials (leaves, papers, rags) and settleable .

Get Price -

Complete Maize Flour Milling Process Introduction

After milling, maize flour is again delivered into Double Bin Sieve 2 for screening. (Read more: Cost of Setting up a Maize Mill in Uganda >>) Maize Flour. Over such cycling of maize milling process, maize flours can meet different classifiion standards. Depending on maize flour content and particle size maize flour is classified into 4 grades:

Get Price -

Rice Milling Manual

Rice milling is the process of removing the husk and bran layer to produce white rice. Rice milling can be undertaken as: • A one step milling process where the husk and the bran are removed in one pass and white rice is produced directly from the paddy. • A twostep process where the husk and the bran are removed separately, and brown rice is produced as an .

Get Price