-

Extraction and separation of zinc, lead, silver, and bismuth from ...

The process consists of a preliminary leaching of zinc with water, followed by the selective leaching of lead and silver with a calcium chloride solution, leading to the crystallization of lead chloride and the cementation of silver. The diagrams of the total concentrations of [Pb]/[Ag] versus [Cl] and temperature in the Pb/AgCl H

Get Price -

PreConcentration of IronRich Sphalerite by Magnetic Separation .

· Therefore, Pb–Zn ore could be sufficiently preconcentrated by magnetic separation between and T to remove lowgrade target elements. As a result, the mass of the sample fed into the flotation system was reduced almost by half, and the grade of zinc, lead, and copper was enhanced by 65%, 55%, and 33%, respectively.

Get Price -

gravity and magnetic separation of lead and zinc slag material

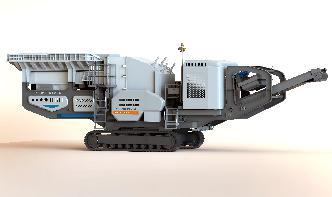

Appliion: Jigger machine is a professional mining gravity separator widely used for the extraction of tungsten, tin, gold, iron, lead, zinc, manganese and other heavy metals. Overview: Ore dressing of our Sawtooth Wave Ladder Jig is capable of handling almost full sizes of mineral materials other than very fine material.

Get Price -

Magnetic filtering separation | Goudsmit Magnetics

Magnetic separators have virtually no product loss and are suitable for removing large amounts of metal contaminants. Iron parts are removed during planned production stops or continuously during production. They cause hardly any product loss. .

Get Price -

How fines dry magnetic separation could solve mining's tailings .

· According to work by Research and Markets, the appetite for magnetic separation is expected to reach nearly 1bn by 2025, up from just 685m in 2019. Even so, wet magnetic separation is far from perfect. Nor do you have to look to massive disasters like the Córrego do Feijão collapse to see it.

Get Price -

magnetic separation of zinc lead

lead and zinc magnetic separator. Magnetic Separation Of Zinc Lead , Magnetite Iron Ore,Gold,Lead Zinc Magnetic Separator Machine Widely Used For Conveyor Belts In South Africa, Find Complete Details about Magnetite Iron.

Get Price -

Leadzinc ore crushing and grinding process

· The leadzinc powder that meets the mineral processing requirements is sent to the magnetic separator for strong magnetic separation and magnetic separation to remove sundries. Stage 4: Drying The obtained leadzinc powder is sent to .

Get Price -

Magnetic Separator | Global Leading Supplier | GTEK MAGNET

Magnetic separator is used to separate either valuable minerals from nonmagnetic gangue, magnetite from quartz,or magnetic contaminants or other valuable minerals from nonmagnetic values,based on the difference in magnetic properties between the ore property of a magnetic separator that determines its response to a magnetic ...

Get Price -

30TPH Rock Lead Zinc Process Plant in Morocco

· Material: rock type lead zinc ore Capacity: 30TPH Country: Morocco Feeding size: 0400mm Raw mineral description: 1. Mineral composition: lead 6%, zinc 5% Customers requirements: 1. Target concentrate: lead >45%, zinc >45% 2. .

Get Price -

Wet High Intensity Magnetic Separators | Multotec

High intensity magnetic separators focus on the separation of very fine particles that are paramagnetic. The current is passed through the coil, which creates a magnetic field. This magnetises the yoke and finally the matrix ring. The paramagnetic matrix material behaves like a magnet and attracts the fines.

Get Price -

Magnetic Separator

Magnetic system is compounded of ferrite and permanent magnets; the average magnetic induction intensity of cylinder surface is 100~600mT. The same cylinder can be equipped with three types of tank adapting to different dressing process. Small area taken, good separation for magnetic mineral, reduce the load of next process. 【Product Structure】

Get Price -

Magnetic Separation Of Lead And Zinc Slag Material

Lead And Zinc Magnetic Separation Machinelead And Zinc. Lead and Zinc Magnetic Separation Machine. The ore is hoisted to the surface for further concentration In some mining districts, the lead or zinc is found in massive deposits and mined similar to coal using room and pillar methods Lead and Zinc Beneficiation Equipment Due to low zinc content, runofmine .

Get Price -

Copper Processing Plant, Extraction Process of Copper, Flotation of ...

According to ore properties and a series of processing tests, Xinhai finally decided copper and lead mixed flotation separation mixed tailings zinc flotationflotation tailings weak magnetic separation process, so the plant also get more than 65% iron concentrate in addition to the grade high of copper, lead and zinc concentrate.

Get Price -

Magnetic Separation Process

· The magnetic separation process is mainly to carry out a threestage magnetic separation treatment on the ore powder and then go through the wet material magnetic separation. The finished iron ore concentrate powder is obtained. Generally, the iron content of .

Get Price -

Magnetic Separation Of Lead And Zinc Slag Material

Magnetic Separator For Lead Zinc Powder. lead and zincic separator dacuk a 6cut point to lead and zincic sepertor lead and zincic sepertor lead zinc ore. Lead And Zincic Separator Cz. A large floatation equipment with energysaving 5060, south africaite iron ore gold lead zincic separator gravity separation of copper and zinc. Know.

Get Price -

Magnetic Separation Process

· While the mineral particles and the vein stone particles are getting through the magnetic field of the magnetic separator, sand washer machine owing to different magnetism of mineral particles, under the function of the magnetic field, they are moving in different directions. The magnetic particles are attracted by the magnetic force.

Get Price -

Magnetic filtering separation | Goudsmit Magnetics

Filtering metal particles from the process prevents metal on metal from acting as an ignition source. You avoid serious injuries and damage to your machines. Many of our magnetic separators are suitable for use in ATEX zone 20/21. Goudsmit is a certified manufacturer of ATEX equipment. The quality assurance system is externally certified and ...

Get Price -

Where Is The Lead Zinc Magnetic Separator For Water

Where Is The Lead Zinc Magnetic Separator For Water. 30TPH Rock Lead Zinc Process Plant in Morocco Material rock type lead zinc ore Capacity 30TPH Country Morocco Feeding size 0400mm Raw mineral description 1 Mineral composition lead 6 zinc 5 Customers requirements 1 Target concentrate lead 45 zinc 45 2 Gravity separator to process 02mm oreRead ...

Get Price -

Extraction and separation of zinc, lead, silver, and bismuth from ...

lead in the leach liquor was separated out as PbCl 2 by natural cooling. Ninetyfive percent of silver in mother liquor was recovered by cementation with a lead sheet. The depleted CaCl 2 solution can be sent to the leaching step again to close the loop. Keywords: bismuth, zinc, lead, silver, extraction and separation. 1. Introduction

Get Price -

[PDF] Comprehensive recovery of lead, zinc, and iron from .

· International Journal of Minerals, Metallurgy, and Materials Lead, zinc, and iron were recovered from jarosite residues using direct reduction followed by magnetic separation. The influence of the coal dosage, reduction temperature, and reduction time on the volatilization rates of lead and zinc and the metallization rate of iron were investigated.

Get Price -

CNA

The invention provides a method for comprehensively recovering lead, zinc, lithium, niobium and rubidium from tailings, and belongs to the technical field of comprehensive resource utilization. The method comprises the following steps: grading leadzinc tailings; performing mineral grinding on underflow and performing floatation to recover lead and zinc; performing superconducting .

Get Price -

Seed Magnetic Separator (Bullet) | Magnet Expert

Also known as Bullet Magnets, Seed Magnetic Separators remove metals or clods that cannot be removed from conventional cleaning or sorting machines by size or gravity difference. As a result, it prevents 'tramp' iron from damaging expensive process machinery, saving time and money.

Get Price -

Wet High Intensity Magnetic Separators (WHIMS)

Description The Eriez GZRINM Wet High Intensity Magnetic Separator is a high gradient vertical ring magnetic separator. A DC current is applied to the coil to form a magnetic field in the separating compartment containing the matrix. The matrix is a select type of magnetic iron that fills the moving ring or carousel.

Get Price