-

Chemical safety: Lead poisoning

· Lead has many uses; therefore, there are many potential sources of exposure. Important sources include environmental contamination from the recycling of leadacid batteries and from poorly controlled lead mining and smelting operations; the use of leadcontaining traditional remedies; lead ceramic glazes used in food containers; lead pipes and other lead .

Get Price -

On the Kinetic Behavior of Recycling Precious Metals (Au, Ag, Pt, .

· Abstract The recycling and recovery of precious metals from secondary materials, such as wasteprinted circuit boards, are an important area of circular economy research due to the limited existing resources and increasing amount of ewaste produced by the rapid development of technology. In this study, the kinetic behavior of precious metals Au, Ag, Pt, .

Get Price -

Risk Management Strategy for Lead

Contamination of terrestrial and aquatic environments by lead can occur in many ways, such as deposition of lead from the atmosphere (Stafilov et al. 2010), erosion of rocks containing lead (Smith et al. 2009), disposal of leadbased products such as lead shot and pellets (Chrastný et al. 2010), historical use of leadbased pesticides (CCME 1999), and release to water and .

Get Price -

How a Gold Mining Boom is Killing the Children of Nigeria

· The lead poisoning crisis in Zamfara is unparalleled, but smallscale mining and other industrial activities — including leadacid battery and electronics recycling — create lead contamination that afflicts children worldwide.

Get Price -

Lead Acid Battery Recycling Market Size, Industry Share

In SLAB the first step for recycling is collection and separation for effective management of lead acid battery recycling. Hydrometallurgy process involves the use of the aqueous chemical solution to recover metal from its ore. Pyrometallurgical process includes calcination, roasting, smelting, and .

Get Price -

Smelting and refining | KGHM Corporate Website

The Cedynia Wire Rod Plant is a copper rolling mill that processes electrolytic copper produced in the smelter/refineries, Głogów and Legnica. Production is carried out with a modern installation for the production of wire rod using the Contirod method, without the use of billets. Also, copper wire Upcast is produced.

Get Price -

Our history l Umicore | Umicore

The background story. The history of Umicore goes back more than 200 years. It all started with the coming together of a number of mining and smelting companies, which gradually evolved into the materials technology and recycling company Umicore is today.

Get Price -

Used lead battery industry is 'world's worst polluter'

· The second most polluting industry was mining and ore processing, with up to million. The International Lead Association responded with a statement claiming the recycling rates of lead batteries had been a success story in recent years, with 99% of ULABs in Europe and North America now collected and recycled.

Get Price -

Lead acid battery recycling for the twentyfirst century | Royal ...

· Despite its success, there are still a number of drawbacks of the pyrometallurgical Pb recycling process, primarily related to operational and environmental concerns [].Smelting has a high energy demand due to the high operating temperatures, while the use of carbon as a fuel leads to the generation of CO high energy demand in conjunction with the .

Get Price -

Lead

Lead, a naturally occurring metal, is abundantly found throughout the Earth. It has been used in a wide variety of products including gasoline, paint, plumbing pipes, ceramics, solders, batteries, and even cosmetics. Lead is hazardous to our health. Due to health concerns, in 1973, the federal government began to phase out lead in gasoline and ...

Get Price -

Impacts of mining and smelting activities on environment and .

Chemical changes are caused by the dispersion of extracted materials or chemical agents used in mining or ore processing (flotation, extraction, etc.), which lead to changes in the chemical composition of the natural environment.

Get Price -

Automobile Industry Largest Source of Lead Pollution Today

· The report finds that the North American automobile industry is responsible for the release or transfer each year of more than 300 million pounds (136,508 metric tons) of lead through mining, smelting, manufacturing, recycling and disposing of leadcontaining automotive components — primarily batteries and through normal vehicle use.

Get Price -

Urban mining for metals flashes electronic trash into treasure

· Tour said that with more than 40 million tons of ewaste produced globally every year, there is plenty of potential for "urban mining." Metals settle at the bottom of a vial after being separated from other components in a crushed circuit board through flash Joule heating. The process developed at Rice University could lead to "urban ...

Get Price -

Uses of Lead | Lead Deposits and Resources

In recent years, lead was mined domestically in Alaska, Idaho, Missouri, Montana, and Washington. In addition, secondary (recycled) lead is a significant portion of the global lead supply. World consumption of refined lead was million metric tons in 2010. The leading refined lead consuming countries were China, the United States, and Germany.

Get Price -

Scientists warn of links between soil pollution and heart disease

· Lead is a naturally occurring toxic metal with environmental contamination through mining, smelting, manufacturing and recycling. Studies have found associations between high blood lead levels and cardiovascular disease, including coronary heart disease, heart attack and stroke, in women and in people with diabetes.

Get Price -

Metal Types and Recycling Process

· The main stages of the metal recycling process are as follows: 1. Collection The collection process for metals differs than that for other materials because of higher scrap value. As such, it is more likely to be sold to scrap yards than sent to the landfill. The largest source of scrap ferrous metal in the is from scrap vehicles. 6

Get Price -

Lead: Past, Present, and Future | Electronic Design

· Lead Recovery and Recycling Recovery of lead is well established, with metal smelting operations using both asmined ores and endoflife product recovery streams as feedstocks. The inputs for...

Get Price -

Lead poisoning | National Health Portal Of India

Mining, smelting, manufacturing and recycling activities, and the continued use of leaded paint, leaded gasoline, and leaded aviation fuel (in some countries) are important sources responsible for environmental contamination. Drinking water supplied through lead pipes or pipes joined with lead solder may contain lead.

Get Price -

Why is lead smelting bad? Explained by FAQ Blog

· Smelting gold is accomplished by using high pressure, heat and various chemicals to breakdown the ore and melt the gold to separate it from the impurities. The gold must be heated to an excess of 1046 degrees Celsius or 2150 degrees Fahrenheit. What is US ore?

Get Price -

Lead acid battery recycling for the twentyfirst century

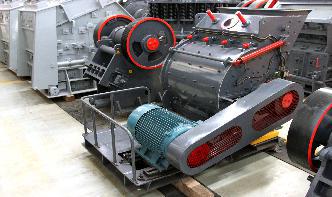

· Smelting is a hightemperature operation, typically operating at 1100–1300°C, where metallic lead can be recovered via reduction with carbon powder. Once the lead paste has been reduced to metallic Pb it can then be refined with the metallic lead grids [ 9 ]. Figure 2.

Get Price