-

milling process of clay

Through process of kaolin clay mill, Process Flow Chart Of Aggregate Plant, ultrafine mill for fine clay powder production, . Click Chat Now. More. Clay Processing US EPA. paragraphs describe the steps used to process each of the six egories of clay. Table summarizes these processes by clay type.

Get Price -

Industrial Minerals

Kaolin differs from other clays by having a low shrinking/swelling capacity and a low ionexchange capacity. Our Kaolin's can be supplied in bulk lump form straight from the mine or processed further by milling, drying and bagging at our Grahamstown factory.

Get Price -

kaolinite clay processing

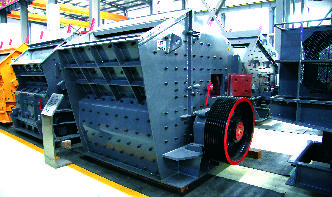

The kaolinite dry mining process is a simple and economical process. The ore is crushed to by a hammer crusher and fed into the cage mill to reduce the particle size to The hot air in the cage mill reduces the moisture of the kaolin from about 20% to 10%.

Get Price -

Kaolin Grinding Mill

10/11/2011 · In the kaolin mining process, crushing is the first step. Using the crushing plant, we get kaolin particle, then using the grinding plant with one type of kaolin mill, we get kaolin powder. Kaolin clay is formed from the weathering of silica rich rocks such as granite and gneiss, it occurs with feldspar and quartz.

Get Price -

kaolin clay process

SBM is a leading and pioneering enterprise with the most advanced international level in RD, manufacturing and selling of largescale crushing screening plants, industrial milling equipments and beneficiation plants.

Get Price -

process of kaolin clay mill

T05:03:57+00:00 Production Process kaolin. Firing is the most important manufacturing process stage, because, when the semihardened elements travel through the kiln, they undergo fundamental transformations in their physicochemical properties The processed pieces are subjected to a hightemperature thermal cycle up to 1300 C The length of the kiln .

Get Price -

Kaolin Milling And Processing

09/10/2007 · May 24, 2016 The first step in processing kaolin clay is to slurry it in a blunger with water and a dispersing agent. Degritting using screens, cyclones and hydroclassifiers is the next step. The minus 325 mesh degritted clay is fractionated using centrifugal sizers to produce the fine fractions demanded by the various markets.

Get Price -

Kaolin Clay Purifiion Equipment And Process Flow | LZZG

Raw ore → crushing → mashing → sand removal → cyclone classifiion → flakes → centrifuge classifiion → magnetic separation (or bleaching) → concentration → filter press → drying → ceramic grade or paper coating grade products. 1. Kaolin clay production line equipment – hydraulic classifiion equipment

Get Price -

Kaolin clay processing

9. The process of claim 8, wherein said hot dilute deflocculated aqueous suspension of fine particlesize hydrated kaolin clay contains from about 36% to 41% solids and is dewatered to about 55% to 60% solids in said electrically augmented vacuum filter. 10. The process of claim 7, wherein said dilute deflocculated aqueous suspension is heated ...

Get Price -

A Look Behind the Process of Kaolin Clay Calcination

15/12/2021 · A Look at the Process of Calcining Kaolin Clay Kaolin calcination is often conducted in a rotary kiln, a thermal processing device used in a number of different industries to cause chemical ...

Get Price -

kaolin clay processing flow chart

flowchart of kaolin production. 11 25 Clay Processing. A process flow diagram for kaolin mining and dry processing is presented in Figure, and Figure illustrates the wet processing of kaolin. In the dry process, the raw material is crushed to the desired size, dried in rotary dryers, pulverized and airfloated to .

Get Price -

kaolin process to pop

methods of beneficiation kaolin clay Grinding Mill China chinagrindingmill 2013 04 10 methods of,Kaolin beneficiation process, kaolin ... kaolin process to pop ... process flow chart of meta kaolin

Get Price -

kaolin milling and processing

Kaolin Grinding Mill. Nov 10, 2011 0183 32 Kaolin mining In the kaolin mining process, crushing is the first step Using the crushing plant, we get kaolin particle, then using the grinding plant with one type of kaolin mill, we get kaolin powder Kaolin clay is formed from the weathering of silica rich rocks such as granite and gneiss, it occurs with feldspar and quartz...

Get Price -

Effect of ball milling process on the structure of local clay and its ...

01/03/2017 · The effect of ball milling process on the properties of the natural local clay including structural changes and adsorption capacity for the removal of Ni(II) ions from aqueous solutions, was investigated. The local clay was ground at varying times from 5 to 20 h with a 10:1 or 20:1 weight ratio of the balls to powder, which produced six different ball milled clays (BM .

Get Price -

Opacifying kaolin clay pigments having improved rheology and process .

An opacifying structured kaolin clay material with improved rheological properties manufactured by a process which comprises the sequential steps of: A. in a first stage, mixing kaolin clay particles with calcium carbonate, water and a hydroxide component to form a mixture containing a comineral blend; and

Get Price -

Kaolin Mining Process Explained | miningpedia

04/02/2021 · Openpit mining of kaolin must strip the loess on the surface of the ore body. After stripping, there are still loess and other debris on the surface of the ore body, you must further clean up the ore deposit.

Get Price