-

allmineral – allair® – sustainable dry processing | allmineral ...

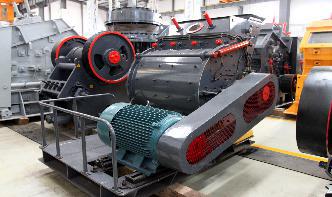

allair®air jigs process grain sizes of up to 50 mm. They are also suitable for sorting primary and secondary raw materials, provided that the substances to be separated feature different densities. Appliions: coal, slag and recycling materials Throughputs ranging from 20 to 65 t/h per machine unit Grain sizes from to 50 mm

Get Price -

Why Corex

· we convert coal ash and slag into useful materials two feedstocks coal ash or steel slag and co2 two products precipitated calcium carbonate (pcc) fine cement aggregate or formed goods advantages for coal ash slag management • low energy ambient temperature/pressure • low cost alytic • high throughput • clean manufacturing .

Get Price -

how to separate coal and iron fillings

how to separate coal from slag how to separate coal and sand equipment. how to separate coal and iron fillings KAMY is the worldwide leader in manufacturing hydraulic cutters road headers tunnel support systems and other specialized machinery used in the tunneling mining and construction industries Read more.

Get Price -

TENORM: Coal Combustion Residuals | US EPA

· Radioactive materials that are naturally included in coal's composition are also combusted during this process. When combustion is completed, the naturally occurring radioactive materials mostly end up in fly ash, bottom ash and boiler slag . About 10 to 20 percent of fly ash, bottom ash and boiler slag consists of TENORM.

Get Price -

USB1

The present invention, therefore, provides stage crushing method for recovering precious metals from slag produced by a coal burning furnace or boiler comprising: a plurality of crushing steps, wherein each crushing step produces slag particles having successively smaller particle diameter sizes, said crushing steps continued until a final desired particle diameter sized is obtained; .

Get Price -

Coal mines to turbines: how energy shapes the Welsh landscape .

· Photographer Richard Jones's Energy+Notion project tells the story of energy in Wales, from the remnants of coal mining that shaped its towns and landscapes to the new windfarms springing up ...

Get Price -

Preparation and Reaction Mechanism Characterization of Alkali .

· After mixing coal gangue and slag powder evenly, the alkali activator was added and stirred with cement mixer for 5 min, poured the fresh paste into steel molds quickly (40 mm × 40 mm × 40 mm) and vibrated them for 60 s on an electric vibration table to remove residual air.

Get Price -

Investigation on cocombustion of coal gasifiion fine slag .

· Froth flotation is an effective method for recycling carbon from lowrank coal by utilizing the difference in the hydrophobicity of the surface of component minerals [9]. It is feasible to separate residual carbon from gasifiion fine slag by froth flotation [10].

Get Price -

Environmental radiological risk assessment of a coal ash and slag ...

A separate assessment performed on an example of reference plants showed that the use of activity concentrations in organisms as input data can result in an order of magnitude smaller estimates of dose rates in comparison to activity concentration in coal and ash as input data. Our study highlighted the need for experimental data in radiological risk assessments to mitigate .

Get Price -

Enrichment of residual carbon from coal gasifiion fine slag by ...

· In addition to flotation, gravity separation is another widelyadopted mineral processing method to separate ash from coal. Because of the high porosity of CGFS, the phenomenon of water penetration is significant. As a result, gravity separation is proposed better suited to the treatment of CGFS.

Get Price -

Integration of coal gasifiion and waste heat recovery from .

· As can be seen, the overall process of coal gasifiion could strictly be divided into two stages based on the TG curves,, firstly, a coal pyrolysis stage for coal char preparation at <950 o...

Get Price -

Recovery of cobalt from slag in a DC arc furnace at Chambishi, Zambia

The intention in this part of the process is to separate the valuable nonferrous metals from the iron and the gangue constituents present in the slag. The desirable area of operation is clearly somewhere in the region where the recovery of cobalt is high, and the recovery of iron to the alloy is still reasonably low.

Get Price -

Vanadium Recovery from Fume Dust and SlagSlag/Dross .

Vanadium is widely spread in earth crust. Vanadium extraction is achieved through the recovery of vanadiumcontaining flue dust and smelting slag. Apart from minerals patronite, vanadinite, sulvanite, sefstromite, vanadium titanuomagnetite ore, vanadium also exists in stonelike coal, crude oil and bitumen.

Get Price -

Characterization of unburned carbon separated from power plant slag .

· Moving the magnet over the surface of the stered particles from the studied slag sample led to the separation of fractions with magnetic and nonmagnetic characteristics. Afterwards, the separated fractions were weighed and examined for LOI values. Separation in the rising water stream was carried out at a test stand depicted in Fig. 2.

Get Price -

Method for precious metal recovery from slag

the present invention, therefore, provides stage crushing method for recovering precious metals from slag produced by a coal burning furnace or boiler comprising: a plurality of crushing steps, wherein each crushing step produces slag particles having successively smaller particle diameter sizes, said crushing steps continued until a final .

Get Price -

The Finished Part: Coal Slag

Boiler slag is the molten material (ash and incombustible) that is sent to a quenching water bath. The quenching process immediately fractures the molten material producing a coarse, hard, black, angular, glassy material sometimes call black beauty. This coal slag is used for a variety of industrial appliions including abrasive blasting.

Get Price -

Slag

The smelting of copper, lead and bauxite in nonferrous smelting, for instance, is designed to remove the iron and silica that often occurs with those ores, and separates them as ironsiliebased slags. [10] Copper slag, the waste product of smelting copper ores, was studied in an abandoned Penn Mine in California, USA.

Get Price