-

principles of cone crushers

Cone Crusher Working Principle Animation Engineering .the working principle of cone crushers is explained to understand what appliion to best use the fine cone crusher in. If you want to learn about our products, please call or write mail consultation. Send Email: [email protected] If you are interested in our products, please contact us. Send Inquiry Get Latest .

Get Price -

Types Of Crusher

According to the working principle, crushing machines are divided into the following types: cone crusher. jaw crusher. impact crusher. These are the most basic distinctions. There may also be subtypes of these machines. For example, impact crushers have varieties such as vertical shaft crushers or tertiary crushers. Kırıcı Tipi.

Get Price -

The working principle of traditional cone crusherquarry crusher ...

· The working principle of the cone crusher is very simple, mainly relying on the force of extrusion to crush materials. The motor will drive the upper eccentric sleeve to rotate through the middle transmission device, so that the moving cone rotates and swings in the crushing chamber. The stones are are squeezed, rubbed between mantle concave, and .

Get Price -

Principles Of Operation Of The Cone Crusher Xsm Grinding

Cone Crushers. Cone crushers are used in AG and SAG grinding circuits to increase tonnage by effectively dealing with any pebble (critical size) buildup problem. Normally, heavy duty shorthead crushers are employed to crush pebbles. Power and crusher cavity level are . View Details Send Enquiry principle of crushing and grindingimpact

Get Price -

FULL HYDRAULIC CONE CRUSHER

PDF Advantage of Hydraulic Cone Crusher The cone crusher can feed the ore with full load. It can be directly fed materials without vibration feeder. The jaw crusher requires that the ore feeding must be even and not full, the materials in the jaw crusher chamber shall not exceed 2/3 of the crushing chamber height. Optimized cavity, higher capacity

Get Price -

Cone Crushers — SRP

cone crushers are an excellent choice in secondary, tertiary, quaternary and pebblecrushing appliions. They are equipped with the hydraulic Hydrosettrade; system, which provides safety and settingadjustment functions. Our crusher automation system delivers realtime performance management, enabling you to monitor and optimize crusher performance .

Get Price -

Advances in Mechanical Engineering 2021, Vol. 13(3) 1–12 Robust ...

· crusher are used for primary crushing while cone crusher is applied in secondary and tertiary The main performance parameters of crushers include particle size, shape, and output. After years of develop ment, researchers have studied the cavity shape, wear, operation model, and power consumption of the

Get Price -

What is the working principle of the Cone Crusher?

Specifically with a cone crusher, there are two cones that create pressure when they meet together at their apexes inside a chamber with gaps between them to allow for liquids to escape. This causes the particles to be compressed into finer material, or into liquid form if it is already in liquid form. Promoted by The Penny Hoarder

Get Price -

cone crushers theory

Cone Crusher Working Principle Animation Engineering. Aug 15, 2012· Cone crusher has a less steep crushing chamber and more parallel zone between crushing zones. Cone crusher parts. It breaks the rocks by squeezing it between the gyrating spindles. These spindles are fully covered with resistant mantle and a manganese bowl liner covers the hopper.

Get Price -

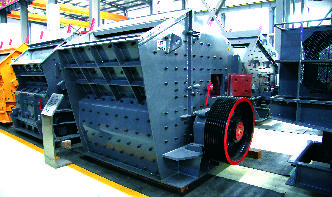

(PDF) Design of Impact stone crusher machine

· Based on the mechanism used crushers are basically of three types; namely, Cone crusher, Jaw crusher, and Impact Crusher. The main objective is to design impact stone crusher. Impact stone crusher ...

Get Price -

cone crusher principles of operation

Cone Crusher Working Principle Pdf. principle of cone crushers pdf . working principle, cone crusher operation principles is one of the most commonly used highway,refractory,road heavy industry get. . Get Price And Support Online "Computer Aided Design of Jaw crusher" ethesis. احصل على السعر . The Working Principle of Jaw Crusher YouTube Click to view on .

Get Price -

CONE

Cone crushers are used by both the aggregate producing and the mining industry. Both industries are interested in increasing the product quality while at the same time lowering the production costs. Prediction of crusher performance has been focused on, since crushing is a vital process for both industries. In this thesis a method for prediction of cone crusher .

Get Price -

working principles of cone crushers

Cone Crushers Working Principle . When Cone crusher is working, the motor drives the eccentric bush via bevel pinion gear. Mantle core is forced to swing by the eccentric bush, which makes the mantle sometimes close to the concave, and sometimes far away from concave. The raw materials are pressed, impacted and finally crushed in the crushing ...

Get Price -

Crushers

Compressive crushers that press the material until it breaks, and impact crushers using the principle of quick impacts to crush the material. Jaw crushers, gyratory crushers, and cone operate according to the compression principle. Impact crushers, in turn, utilize the impact principle. Jaw crushers . Jaw crushers are mainly used as primary crushers. Their main .

Get Price -

cone crusher working principle animation

Cone Crusher Working Principle While the eccentric shaft rotating the materials are continuously squeezed and compressed between the moving and fixed steel thus the materials gradually become smaller and pass down through the discharge port. The required final size is adjustable and determined by the gap between the two crushing steel at Get Price

Get Price -

What Is the Cone Crusher Working Principle?

The unique working principle of cone crusher enables it to be useful for primary crushing, secondary crushing and final crushing as well. With the higher production and higher quality, it is becoming more and more popular among construction companies. What's more, its lower cost and easier maintenance promote its popularity.

Get Price -

Cone Crushers — Mining and Rock Technology

CS and CH cone crusher series. CS and CH cone crushers provide all the options you need to perform high performance work. With hydraulically adjusted CSS, the option of automation (included in the new generation of cone crushers CH540, CH550 and CS550), a choice of several different crushing chambers, and many other high .

Get Price -

cone crushers data its working principles

Working Principles Of Cone Crushers FOB Reference PriceGet Latest Price Working principles of cone crusher bluesfuse working principles of cone crushers XSD Sand Washer The efficient sand washing machine of XSD series is a kind of cleaning equipment of international advanced level for sand and slag pellets developed on the basis of introducing foreign .

Get Price -

Roll crusher working principle | Henan Deya Machinery Co., Ltd.

· The crushing mechanism consists of a rotating roll 1 and a jaw plate 4. The jaws are mounted on a bolt with a tooth bushing 2 on the core of the roll, with the tip of the tooth sticking forward like a hawk's beak, which can be removed and replaced when the bushing wears out.

Get Price -

® MP Series™ Cone Crushers Brochure

The MP cone begins crushing the material at a high ratio of reduction immediately upon entry into the crushing cavity. This active crush ing motion at the top... Open the alog to page 10 Hydraulics Assure Easy, Fast and Safe Operation Heavyduty hydraulic clamping cylinders provide positive securement of the bowl during crushing.

Get Price