-

formula of critical speed of ball mill

critical speed of of ball mill. Critical Speed Of Ball Mill Formula Derivation 201983 The formula to calculate critical speed is given below N c 42 305 sqtDd N c critical speed of the mill D mill diameter specified in meters d diameter of the ball In practice Ball Mills are driven at a speed of 5090 of the critical speed the factor being influenced by economic

Get Price -

Particle Analysis of Road Materials

Particle size of the asphalt droplets is critical to stability and appliion performance. Asphalt emulsions are manufactured by a highspeed, high shear mechanical device (usually a colloid mill) that divides the asphalt into tiny droplets and disperses it in the water. Typical products have a size range from submicron up to ten microns, with an average particle size in the one to five ...

Get Price -

(PDF) Performance Evaluation of Vertical Roller Mill in

· In this study, an extensive sampling study was carried out at vertical roller mill of ESCH Cement Plant in Luxemburg. Samples were collected from mill inside and around the circuit to evaluate the ...

Get Price -

How to Calculate Trace Length for Highspeed Signals

Calculating signal speed on a PCB. According to physics, electromagnetic signals travel in a vacuum or through the air at the same speed as light, which is: Vc = 3 x 108M/sec = 186,000 miles/second = inch/nanosecond. A signal travels on a PCB transmission line at a slower speed, affected by the dielectric constant (Er) of the PCB material.

Get Price -

Estimation of Mercury Losses and Gold Production by ...

· In this effort, Hg losses in ASGM were derived from the difference between estimates of total Au production and the production reported by conventional gold mining. On the basis of this result, the average ratio of Hg lost to Au produced in ASGM was estimated to be in Africa, in Latin America, and in Asia.

Get Price -

Milling Formulas and Definitions

The Milling Process – Definitions Cutting speed,v c Indies the surface speed at which the cutting edge machines the workpiece. Effective or true cutting speed, v e Indies the surface speed at the effective diameter (DC ap).This value is necessary for determining the true cutting data at the actual depth of cut (a p).This is a particularly important value when using round .

Get Price -

Kolkata Critical Speed Of Ball Mill Formulae

Formula For Critical Speed Ball Mill. formula for critical speed ball mill. The formula for critical speed is CS = 1 2π √(g (Rr) Ball milling is one of the few unit operation that improves with increasing mill diameter. If acceptable results can be obtained with a 12 jar mil, then good result will certainly be obtained with a 72 diameter ...

Get Price -

Failure of Cutting Tools and Tool Wear

Optimizing Cutting Speed Select speed to achieve a balance between high metal removal rate and suitably long tool life Mathematical formulas are available to determine optimal speed Two alternative objectives in these formulas: 1. Maximum production rate 2. Minimum unit cost

Get Price -

Iron ore

Iron ores are rocks and minerals from which metallic iron can be economically extracted. The ores are usually rich in iron oxides and vary in color from dark grey, bright yellow, or deep purple to rusty red. The iron is usually found in the form of magnetite (Fe 3 O 4, % Fe), hematite (Fe 2 O 3, % Fe), goethite (FeO(OH), % Fe), limonite (FeO(OH)·n(H 2 O), 55% Fe) or .

Get Price -

Draft Angle Guidelines for Injection Molding

When designing a part, apply as much draft angle as possible—a general rule of thumb is 1 degree of draft per 1 inch of cavity depth, but that can change with the aforementioned factors. Try following these general guidelines: degrees on all vertical faces is strongly advised. 1 to 2 degrees works very well in most situations.

Get Price -

cement plant calculations kiln, mills, quality, combustion, etc. all ...

Grinding Calculations. Most Frequently Used Grinding Calculators Now Available Online For Cement Professionals. Critical Speed (nc) Mill Speed (n) Degree of Filling (%DF) Maximum ball size (MBS) Arm of gravity (a) Net Power Consumption (Pn) Gross Power Consumption (Pg) Go To Online Calculators.

Get Price -

Hammer Mill: components, operating principles, types, uses, .

· Pharmaceutical uses of Hammer Mill. 1. It is used in pharmaceutical industries to process wet or dry granulations and disperse powder mixtures. 2. It is used in milling pharmaceutical raw materials, herbal medicine, and sugar. 3. It is used in powdering of barks, leaves, and roots of medicinal plants. 4.

Get Price -

Ball Mill Design/Power Calculation

· The approximate horsepower HP of a mill can be calculated from the following equation: HP = (W) (C) (Sin a) (2π) (N)/ 33000. where: W = weight of charge. C = distance of centre of gravity or ...

Get Price -

Complete Moisture Analysis for Wheat

· The grain then equilibrates for 16 to 24 hours before it is milled. However, standard practices do not include a test to determine if moisture equilibrium has been achieved, but instead depend on preset soaking times. The 16 to 24 hour hold time for tempered wheat is typically not long enough for mold to grow.

Get Price -

how do i calculate the critical speed of a mill

Formula To Calculate Critical Speed In Ball Mill. Critical speed of ball mill derive tobias formula to calculate critical speed is given sqtdd n c critical speed of the mill diameter specified in diameter of the practice ball mills are driven at a speed of 5090 of the critical speed the factor being influenced by economic consideration.

Get Price -

Redesign and Structural analysis of agitator shaft for ...

Agitator speed not within ±30% of critical speed Deflection due to 1st impeller ð 1 = F m1 ×l 1 3/3EI ð 1 = Critical Speed (N c1) N c1 = 946/ = Critical Speed (N c2) N c2 = 946/ = Critical Speed of whole system 2 1/ N c = 1/ N c1 2 + 1/ N c2 2 N c = rpm Actual speed of agitator =115rpm which is % of critical speed, hence .

Get Price -

Critical Speed Of Ball Mill Formulae

Critical Speed Of Ball Mill Formula And Derivation Ball mill crusher and rod mill models appeared in the 1970s based on work by . parameters such as appearance functions which derive from measurement .. index and transfer size according to the bond ball calculation equation .. with 12 ball charge and operating. Ball Mill Parameter Selection Power Rotate Speed Steel . .

Get Price -

Acceptable Quality Limit

Acceptable Quality Limit (AQL) In performing sampling inspection, QIMA inspectors exclusively apply the ISO 2859 standard and the tables provided by it. This document, published by the International Organization for Standardization (ISO), is an international standard with equivalents in all national regulations (ANSI/ASQC, NF06022, BS ...

Get Price -

ball mill critical speed formula derivation

Ball Mill Operating Speed Mechanical Operations Solved ... Calculations: The critical speed of ball mill is given by, where R = radius of ball mill; r = radius of ball. For R = 1000 mm and r = 50 mm, nc = rpm. But the mill is operated at a speed of 15 rpm. Therefore, the mill is operated at 100 x 15/ = % of critical speed ...

Get Price -

The critical rotational speed of circular saw: simple measurement ...

critical speed appears also depends on the ratio of collar and saw blade The lowest critical speed n cr min may be calculated from Eq. 3: n f nK cr min = n − 60 0 2 (3) where K is the centrifugal force coeffi cient (a dimensionless constant independent of the rotational speed), f n (0) is the value of natural frequency of the nonrunning saw blade for the nodal diameter n. .

Get Price -

Variables in Ball Mill Operation | Paul O. Abbe®

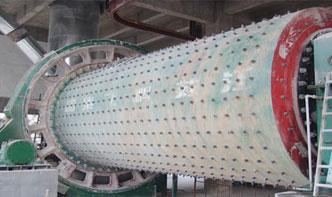

Critical speed (CS) is the speed at which the grinding media will centrifuge against the wall of the cylinder. Obviously no milling will occur when the media is pinned against the cylinder so operating speed will be some percentage of the CS. The formula for critical speed is CS = 1/2π √(g/(Rr) where g is the gravitational constant, R is ...

Get Price