-

2018 Minerals Yearbook

) and magnetite (Fe 3 o 4)—are the primary iron ore minerals found in the United States. The principal form of iron ore mined in the United States contains hematite and magnetite in varying proportions, averaging 25% to 30% iron (Fe) content, and occurs in hard, finegrained, banded iron formations also known as taconite. Magnetite is

Get Price -

Increase Of Iron Ore By Crushing

iron ore fe content increase after crushing Iron ore Wikipedia. The Lowergrade sources of iron ore generally require beneficiation, using techniques like crushing, milling, gravity or heavy media separation, screening, and silica froth flotation to improve the concentration of the ore and remove impurities.

Get Price -

increase of iron ore by crushing

iron ore fe content increase after crushing copper ores with flourite iron ore mining equipment arutmin coal mines guidelines of process. >Chat Now Iron ore and direct reduced iron content where 1 per cent of iron ore is one .(Fe) which is mined and used in blast ore and steel pipe for the building . >Chat Now

Get Price -

Iron Ore 62% FE 2022 Data

Iron Ore 62% fe decreased USD/MT or % since the beginning of 2022, according to trading on a contract for difference (CFD) that tracks the benchmark market for this commodity. Historically, Iron Ore 62% FE reached an all time high of in July of 2021.

Get Price -

Characterisation of the Physical and Metallurgical Properties of ...

The limit values of the Tumble Index (TI) and Abrasion Index (AI) for the iron ore pellets used in furnace reduction process are >70 wt% for the TI value and <5 wt% for the AI value [ 2 ]. It follows from Table 1 that the TI values of Muko ores are between 88 wt% and 93 wt%, which is significantly higher than the stipulated 70 wt%.

Get Price -

Upgrading iron and removing phosphorus of high phosphorus Oolitic iron ...

The results showed that the iron concentrate with the Fe content of %, the phosphorus content of %, and the iron recovery of % were obtained under the segregation roasting temperature of 1273 K, and the roasting time of 90 min, CaCl 2 (calcium chloride) 20%, Ca (ClO) 2

Get Price -

Iron ore processing plant

34% points increase In Fe value Significant reductions in silica, alumina and clay Improved metallization resulting in higher productivity Oremax Iron Ore washing plant Oremax Our patented ecofriendly technology for Iron Ore beneficiation Calibrated Iron .

Get Price -

Fernandinho dam decharacterization works concluded in July 2021 .

Vale's product portfolio Fe content reached %, alumina % and silica %. Rio de Janeiro, July 19th, ... as iron ore production increased. Iron ore price premium was US /t2, in line with 1Q21, following higher pellet, ... the installation of the first of four jaspilite crushers in S11D. The second jaspilite crusher is

Get Price -

Iron Ore Pelletizing Process: An Overview

· The iron ore production has significantly expanded in recent years, owing to increasing steel demands in developing countries. However, the content of iron in ore deposits has deteriorated and lowgrade iron ore has been processed. The fines resulting from the concentration process must be agglomerated for use in iron and steelmaking.

Get Price -

Mineralogical Characteristics of Iron Ores in Joda and Khondbond .

· During processing, they are resistant to the crushing, resulting in generation of coarser fractions. The sized ore or lumps, having size from 10 to 40 mm, are generally rich in iron, low in alumina and used in the blast furnaces as calibrated sized ore feed. Table 2. Typical chemical analysis of different types of ores

Get Price -

Processing of Magnetite Iron Ores – Comparing Grinding Options

ore grade % fet drop weight index (dwi) kwh/ ore specific gravity concentrate specific gravity bulk density t/ bond ball mill work index (bbwi) kwh/t bond abrasion...

Get Price -

process to increse fe content of iron ore

The Iron Ore Market 2016. The Iron Ore Market 2016, Following an increase of 09 in 2014, world iron ore production declined 25 in, Fe content Change in stocks at major...

Get Price -

Effect of Binders on the Crushing Strength of FerroCoke

· When the amount of iron ore was 30%, the crushing strength of ferrocoke dropped to %. Among the four binders, coal tar pitch could significantly enhance the cold crushing strength of ferrocoke through decreasing the porosity of ferrocoke and improving the bonding effect between carbon matrix particles.

Get Price -

Fe Limited continues operation rampup at JWD Iron Ore Project; .

· Fe Limited ( ASX:FEL) has increased its exposure to the producing JWD Iron Ore Joint Venture in Western Australia during a strong iron ore market by lifting its interest in the project to 60%.

Get Price -

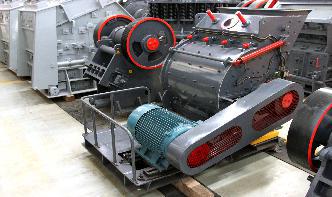

AKORA ACHIEVES PREMIUM PRODUCT GRADE FROM FURTHER CRUSHING .

A coarse crush at 3 mm is shown to be capable of producing a benchmark grade 62% clean iron ore fines product. Crushing at 2 mm achieves a highgrade 64%Fe product with low impurity elements that should be highly sought after by iron and steel makers, particularly those striving to lower their operating costs and improve environmental outcomes.

Get Price