-

ball mill electrical operation principle | Mining Quarry Plant

Ball mill operating principle is as following. The material enters spirally and evenly the first warehouse of the milling machine along . electric diagram ball mill – Find the Right and the Top ball mill principle with diagram for your coal handling plant! . Operation manual electric diagram; OPTIONS: 1. What's the difference between Ball Mill and .

Get Price -

What's the Difference Between SAG Mill and Ball Mill

· The working principle of the selfgrinding machine is basically the same as the ball mill, the biggest difference is that the sag grinding machine uses the crushed material inside the cylinder as the grinding medium, the material constantly impacts and grinding to gradually pulverize. Sometimes, in order to improve the processing capacity of ...

Get Price -

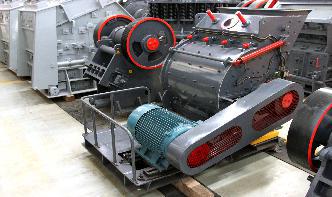

Ball Mill Loading

Ball Mill Loading (dry milling) When charging a ball mill, ceramic lined mill, pebble mill, jar mill or laboratory jar use on a jar rolling mill it is important to have the correct amount of media and correct amount of product. Charging a Dry Mill The general operation of a grinding mill is to have the product impacted between the balls as they tumble. If there are insufficient solids .

Get Price -

ball mill principle of operation

Feb 08, 2017The operating principle of the ball mill consists of following steps. In a continuously operating ball mill, feed material fed through the central hole one of the caps into the drum and moves therealong, being exposed by grinding media. The material grinding occurs during impact falling grinding balls and abrasion the particles between the balls.

Get Price -

coal ball mill working principle used in pf boilers

Ball mill Wikipedia. A ball mill is a type of grinder used to grind, blend and sometimes for mixing of materials for use in mineral dressing processes, paints, pyrotechnics, ceramics and selective laser works on the principle of impact and attrition: size reduction is done by impact as the balls drop from near the top of the shell.

Get Price -

Ball Mill

Operating principles Ball Mills operate by introducing the material to be milled into a rotating vessel which contains a grinding medium ( highdensity balls or rods) and the material is ground (wet or dry) by attrition through the tumbling action of the mill. Slow rotational speeds combined with simple and robust construction make them ideal for grinding hard and abrasive .

Get Price -

describe the working principle f ball mill

The operating principle of the ball mill The operating principle of the ball mill consists of following steps. In a continuously operating ball mill, feed material fed through the central hole one of the caps into the drum and moves therealong, being exposed by grinding media. The material grinding occurs during impact ...

Get Price -

Endrunner mill and Edgerunner mill: Operating principles, Uses

· Advantages of Endrunner mill and Edgerunner mill. 1. It produces fine particles. 2. Requires less attention during the milling operation. Disadvantages of Endrunner mill and Edgerunner mill. 1. It is not suitable for milling sticky materials. 2. Machine noise leading to noise pollution. References. Sud Sushant and Kamath Archana (2013 ...

Get Price -

SIZE REDUCTION

Ball Mill Principle It operates on the principle of impact and attrition between the rapidly moving balls and the powder material, both enclosed in a hollow cylinder. Parts Consists of a hollow cylinder mounted on a metallic frame such that it can be rotated along its longitudinal axis. Cylinder contains balls occupying 30–50 % of mill volume. Weight of ball is constant; Size .

Get Price -

Cement Ball Mill Basic Operation Principles Examples

· Apr 30 2020 Cement Ball Mill Principle Of Operation Cement ball mill principle of operation fob reference priceget latest price ball mill principle of operation this article contains an animation of what the contents of a ball mill do during operation a ball mill a type of grinder is a cylindrical device used in grinding or mixing materials like ores a . Get Price. What .

Get Price -

principle operation ball mill

· Ball Mill: Operating principles, components, Uses . A ball mill also known as pebble mill or tumbling mill is a milling machine that consists of a hallow cylinder containing balls; mounted on a metallic frame such that it can be rotated along its longitudinal axis The balls which could be of different diameter occupy 30 – 50 % of the mill volume and its size depends on the feed and mill

Get Price -

Ball Mill Parameter Selection Calculation

· 1 Calculation of ball mill capacity. The production capacity of the ball mill is determined by the amount of material required to be ground, and it must have a certain margin when designing and selecting. There are many factors affecting the production capacity of the ball mill, in addition to the nature of the material (grain size, hardness, density, temperature and .

Get Price -

bico ball mill operation instruction pdf

bico ball mill operation instruction pdf. Lechler spray nozzles and engineered systems bico ball mill operation instruction pdf,Maintaining of the adjusted spray direction by the »memory effect« Very easy handling pipe connector More informationen on MEMOSPRAY® (PDF) >>Projects SX Kinetics, Inc Specialists in Solvent Extraction and 20 Apr 2014 Designed and manufactured a .

Get Price -

How Does a Hammer Mill Work?

Hammer mills work on the principle that most materials will crush, shatter or pulverize upon impact: The Process: • Material is fed into the mill's chamber through the . feed chute, typically by gravity. • The material is struck by . ganged hammers (generally rectangular pieces of hardened steel) which are attached to a . shaft. that rotates at high speed inside the mill's . grinding ...

Get Price -

High energy ball milling process for nanomaterial synthesis

The alloying process can be carried out using different apparatus, namely, attritor, planetary mill or a horizontal ball mill. However, the principles of these operations are same for all the techniques. Since the powders are cold welded and fractured during mechanical alloying, it is critical to establish a balance between the two processes in ...

Get Price -

What Are the Differences between Ball Mill and Rod Mill?

· 1. Ball mill. a Ball mill has a wide range of appliions. It can grind metal ore and nonmetal ores, which is suitable for hard materials, such as quartz, gold ore, copper ore, iron ore, potash feldspar, etc. b Ball mill is also can be applied in the industries such as cement, construction materials, fireproofing materials, glass, and ceramics.

Get Price -

Ball mill media optimization

the effect of any ball mill design or operating variable. Along with plant testing difficulties, only fairly large changes in circuit performance could be linked to a media size change. • Population balance modelling was deemed unsuitable for this purpose. As noted by Meloy et al., (1990), any number of different breakage rate curves can be derived from the same mill feed and product .

Get Price -

Process Engineering with Planetary Ball Mills

· Planetary ball mill is a fast, simple, and costeffective technology, which provides the possibility of an intensive mixing on lab and pilot scales. (Burmeister Kwade, 2013; Piras, Fernández ...

Get Price -

ball mill schematic diagram and operating principle

ball mill operation wth equipment diagram. Ball Mill Operating principles, components, Uses, Advantages and. Jan 11, 2016 A ball mill also known as pebble mill or tumbling mill is a milling machine that consists of a hallow cylinder containing balls; mounted on a metallic frame such that it can be rotated along its longitudinal axis. The balls

Get Price -

Operating Principles Of Ball Mill

· Design and operating principle A ball mill is a hollow drum rotating around its horizontal axis It is filled with grinding balls impact elements As a result of rotation balls on the internal drum surface lift and then fall down under the gravity action. Get Price; Variables in Ball Mill Operation Paul O Abbe . A Slice Mill of 72 diameter by 12 wide would replie the result .

Get Price -

ball mill operation principle

Ball Mill Working Principle. To be chosen according to the grinding material, material is composed of a ball mill feed end of the hollow shaft is arranged in the tube body, when the ball mill cylinder rotation time, grinding body due to inertia and centrifugal force, the effects of friction, making it attached to the cylinder liner on the cylinder body away, when taken to the height of a ...

Get Price -

Ball Grinding Mill Operation Principle

ball mill operating principle stone crusher quarry. grinding: an overview of operation and design – minerals research, ball mills . . . . autogenous mills . grinding circuits . open circuit grinding . closed circuit ... principle operation grinding. Ball Grinding Mill Operation Principle. Ball Mill Physical Detailed Construction And Working Principle. 24 Jun 2012 The working .

Get Price -

ball mill principles of operation

The operating principle of the ball mill Feb 08, 2017 The operating principle of the ball mill consists of following steps. In a continuously operating ball mill, feed material fed through the central hole one of the caps into the drum and moves .

Get Price -

principle of operation of hydroball mill

Ball Mill: Operating principles, components, Uses, Advantages and. Jul 05, 2020· Advantages of Ball Mills. 1. It produces very fine powder particle size less than or equal to 10 microns. 2. It is suitable for milling toxic materials since it can be used inpletely enclosed form. 3. Has a wide appliion. 4. It can be used for continuous operation. Get a quote; The working principle of .

Get Price -

Ball Mill Principle, Construction, Uses, Advantage, Disadvantage.

· The ball mill operates on the principle of impact and attrition. In this, impact occurs between fast moving balls and the powder material while the attrition mode comes in action when the hollow cylinder rotates on its longitudinal axis. All is occurs at low speed and the balls roll over each other. Construction. Ball mill consist of a hollow cylinder mounted/fitted on a metallic .

Get Price