-

Effects of surfactant additives during ball milling on the ...

02/09/2022 · These results indie that CTAB was identified as a suitable surfactant candidate for the ball milling process and the optimum sintering condition was 1290–1300 °C for 2–4 h. Therefore, adding surfactant additives in ball milling process is a promising approach to improve the electrical and piezoelectric properties of BCZT ceramics.

Get Price -

Continuous Dry Grinding Ball Mills Dominicaball Mill

Attritor stirred ball mill sepor intritor stirred ball mill sepor incThe attritor mills 010e500 010e510 can be operated in a batch or continuous mode utilizing either dry grinding or wet grinding when used in continuous grinding the, continuous dry grinding ball mills dominica

Get Price -

Continuous Ball Mill Ball Mill Manufacturer India Ball

The Continuous Ball Mill. We are a leading ball mill manufacturer, exporter when it comes to continuous ball mills. Our commitment to quality is the main reason why we deliver worldclass continuous ball mills. Our stainless steel ball mills are used to grind ores and minerals from a feed size of 6mm and Moh's hardness upto 5 to d97 6um.

Get Price -

contineous ball millscf 6 round rod milling machine

How to optimize a 6 pound ball mill to safely and effectively ball mill homemade black powder. Ball Millone important stone crusher and grinding machine. Illustration of How Ball Mill Works Ball mills are generally used to grind material 14 inch and finer down to the particle size of 20 to 75 microns. boom bang huge powerful insane . Service ...

Get Price -

Custom Ball Mill Products | Neumann Machinery Company

Neumann Machinery Company (NMC) ball mills have a long and proven history going back to the early 1900's. The first mill designs originated from EIMCO Company originally loed in Salt Lake City, Utah. ... Continuous Feed Grinding Mills: Ball, Pebble Rod. 3 ft (.9 M) – ft ( M) diameter Overflow Grate Discharge Wet Dry ...

Get Price -

Home

Continuous ball mills for the fine grinding of cocoa liquor, capacities ranging from 400 up to kg/hr; Continuous and batch wise ball mill systems for the fine grinding of chocolate and chocolate related products, capacities ranging from 5 up to kg/hr; Storage tanks and mixers for cocoa liquor, chocolate and chocolate related products

Get Price -

Ball Mill for Sale | Grinding Machine

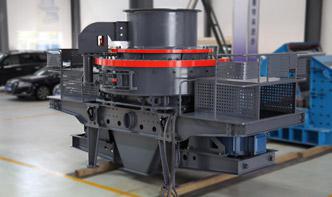

The ball mill is a typical material grinder machine which widely used in the mineral processing plant, ball mill performs well in different material conditions either wet type grinding or dry type, and to grind the ores to a fine size. Main ball mill components: cylinder, .

Get Price -

Planetary Ball Mill BM 1200+

Technical features of BM1200+ series Ball Mill: Low center of gravity, stable performance, compact structure, easy operation, reliable safety, lower noise, small loss. Safety switch is installed on the machine to prevent safety accident if the safety cover is opened while machine is running. Speed ratio selectable 1:2/1:/1:3.

Get Price -

Ball Mills

Our ball mills are industrial grade and designed for continuous operation, equipped with oversize roller bearings and a complete drive system. All wear parts are highly abrasion resistant and replaceable. The capacity, or throughput, of a ball mill is .

Get Price -

Continuous Mills

Continuous Mills are used ball mills in various styles such as continuous, batch, granite lined, Jacketed and nonjacketed. The unique features of the ball mills are its assembly and the workmanship of all the machine parts. The continuous mill supports are from fabried plate section and the base where the bearing blocks are fixed are machined.

Get Price -

Material Handling Systems and Continuous Ball Mill Products

The product range consists of continuous ball mills, rotary klins, material handling systems and many more. are manufactured in compliance with set industrial standards using advanced technological standards. We use quality material while manufacturing these products and also consider client's requirement for customization. Ball Mill

Get Price -

Ball Mill Manufacturers

We offer our clients both batch type ball mills and continuous type ball mills. It finds appliion in mining, building materials and chemical industries. The offered product can be used both for wet and dry grinding as well as mixing. The machine can be used to pulverize even the hardest rock. A ball mill grinds material by rotating a ...

Get Price -

Ball Mill Manufacturer | Neumann Machinery Company

Founded in 1984 with the acquisition of the EIMCO ball, pebble and rod mill product lines. Neumann Machinery Company (NMC) is headquartered in West Jordan, Utah, in the USA just 14 miles south of Salt Lake City. The area is steeped in a rich history in the supply of mining and heavy industrial machinery. The original EIMCO products have been ...

Get Price -

contineous ball mills

25/02/2016 · The Continuous Ball Mill. We are a leading ball mill manufacturer, exporter when it comes to continuous ball mills. Our commitment to quality is the main reason why we deliver worldclass continuous ball mills. Our stainless steel ball mills are used to grind ores and minerals from a feed size of 6mm and Moh's hardness upto 5 to d976um.

Get Price -

continuous ball mill machines spain crushing machines

Continuous Ball Mill Machinery Spain Crushing Machine. 201774 · Continuous Ball Mill Machinery Spain Crushing Machine. A ball mill is a type of grinder used to grind materials into extremely fine powder for use in mineral dressing processes paints pyrotechnics ceramics and selective laser sinteringand works on the principle of impact size reduction is done by impact .

Get Price -

Analysis of holdups in continuous ball mills | Semantic Scholar

Analysis of holdups in continuous ball mills article{Nomura2013AnalysisOH, title={Analysis of holdups in continuous ball mills}, author={Shinichiro Nomura}, journal={Powder Technology}, year={2013}, volume={235}, pages={443453} } S. Nomura; Published 1 February 2013; Materials Science; Powder Technology

Get Price -

Ball Mill Manufacturer | Neumann Machinery Company

Ball Mills Sales Service SALES Continuous Feed Grinding Mills: Ball, Pebble Rod 3 ft (.9 M) – ft ( M) diameter Overflow Grate Discharge Wet Dry Grinding SERVICES Flow Sheet Development Project Commissioning Design Installation Supervision Training Rebuilds Used Equipment Evals Consultations Request a Quote

Get Price -

Optimization of continuous ball mills used for finishgrinding of ...

10/12/2004 · For a constant ball diameter d, the number of balls inside the mill can be calculated as follows (5) n k = 3 2 (D d) 3 L D φ k (1 − ε) The combination of Eqs. (4), (5) gives an expression for the energy input per ball P / n k, which should be proportional to the stress intensity (6) BI ∝ ( P n k ) = π 6 D d 3 c ρ k

Get Price -

Ball mill 1456А of continuous operation for dry material grinding

Ball mill 1456А is designed for dry grinding of ore and nonmetallic raw materials, construction materials of medium hardness. The mill belongs to the tube ball mills of continuous operation with central discharge of ground product. The drum ball mill is used in oremining, mining and chemical and other types of industries.

Get Price -

Optimization of continuous ball mills used for finishgrinding of ...

01/12/2004 · This paper will present some results on the effect of ball diameter (d) and ball filling (J) on breakage parameters for a laboratory ball mill, with a constant powder filling (f c = %) and ...

Get Price -

Refining Ball mill – Royal Duyvis Wiener

The vertical ball mill is used for the processing of highviscous premixed pastes, like chocolate, compound, crèmes, nut and seedpaste. The continuous design vertical ball mill can be used in a 1 – 3 stage refining system, with 1 – 3 ball mills in a sequential row after the premixer.

Get Price -

Ball Mill | Ball Mills | Wet Dry Grinding | DOVE

DOVE small Ball Mills designed for laboratories ball milling process are supplied in 4 models, capacity range of (200g/h1000 g/h). For small to large scale operations, DOVE Ball Mills are supplied in 17 models, capacity range of ( TPH – 80 TPH). With over 50 years experience in Grinding Mill Machine fabriion, DOVE Ball Mills as ...

Get Price -

Ball mill

24/04/2015 · 5. The ball mill is used for grinding materials such as coal,pigments,and fedspar for pottery. Grinding can be carried out in either wet or dry but the former is carried out at low speeds. The advantages of wet grinding are less power consumption,increased capacity,no dust formation etc.. Dis advantages are high wear on the grinding medium ...

Get Price -

Ball and Rod Mills

Laarmann Ball and Rod Mills are ideal for large capacity fine milling and have the best Grinding performance for materials in the dry and wet state. Mail; Internship; Facebook; ... Continuous Ball Mill. Laarmann Group Lab Wizz 320 Micro Ball Mill. LM PBM Planetary Ball Mill. Laarmann Group LM PBM4000 Planetary Ball Mill. LMBM Ball Mill.

Get Price -

continuous ball mills

continuous small ball mill . Continuous Feed Ball Mill 600 x 1200 Continuous Feed Ball Mill 600mm x 1200mm Max Feed Size 10mm Discharge Size 0 0751 00mm Capacity 0 51 t/hr Weight 3 tonne Steel Balls 0 8 tonne Electric Motor 11 KW Ball Mills are used as the final mill stage after crushing This type of Ball Mill is a continuous feed style Built ...

Get Price