-

ASIA LIMITED

Cone Crushers Working Principle :When Cone crusher is working, the motor drives the eccentric bush via bevel pinion gear. Mantle core is forced to swing by the eccentric bush, which makes the mantle sometimes close to the concave, and sometimes far away from concave. The raw materials are pressed, impacted and finally crushed in the crushing chamber.

Get Price -

How Do Concrete Crushers Work

how do concrete crushers work The Skid Steer Concrete Crusher is a heavy duty attachment, ideal for concrete recycle work as well as grinding, block, brick, and stone crushing these into backfill material they do not have to be hauled off the job site, saving thousands of dollars in disposal costs. ...

Get Price -

Concrete Crusher Hire in Es | Stigs Grab Services Ltd

Our concrete crushers are available for hire alongside our grab lorries. This pairing makes the logistical aspects of concrete crushing far easier. Able to pick up and transport large pieces of material around the site, our grab trucks make light work of otherwise challenging tasks. Stig's Grab Hire provide concrete crusher hire for clients throughout Es. Available for varying .

Get Price -

Types of Rock Crushers | Quarry Crushing Equipment | Kemper

Typically, the minimum setting on most primary crushers will be about 4 to 6 inches, as noted above. Compressionstyle jaw, cone, impact crushers, and gyratory crushers are most often appropriate as primary crushing equipment types, though there can be overlap between primary and secondary crushers as far as suitable types. 2. Secondary Crushing.

Get Price -

how do concrete crushers work

The Page Description. May 06, 2021 0183 32 Heavyduty crushing appliions of hardtobreak, high Work Index rocks do prefer doubletoggle jaw crushers as they are heavier in fabriion A doubletoggle jaw crusher outweighs the singletoggle by a factor of 2X and well as costs more in capital for the same duty To perform its tradeoff evaluation, the engineering and design firm .

Get Price -

How to Crush Concrete Slabs Into Stone Sized Pieces | eHow

Step 4. Strike the slab with a sledge hammer about 12 inches from the point where the pickax touches the underside of the slab. Do this repeatedly, and after a short time the slab will break up into small pieces.

Get Price -

The Do's and Don'ts of Curing Concrete | PRO CREW SCHEDULE

· The cracks are formed due to drying shrinkage, plastic shrinkage, and thermal effects. The durability of concrete decreases due to high permeability. 5. The weathering and frost resistance are decreased. The rate of carbonation on the concrete increases. The surfaces are coated with dust and sand, and it leads to lower abrasion resistance.

Get Price -

gyratory crusher pdf stone crusher machine wear parts concave .

The largest primary gyratory crushers cost US million or . crusher design calculation pdf[crusher and mill] how do small concrete crushers work – Mineral Processing Plant. Mineral Processing. May 15, 2014 · Jaw crusher is the better choice because of: 1Jaw crusher can take larger size than gyratory is better adopted to handle clayey ...

Get Price -

12 Most Common Mistakes When Pouring Concrete

· Concrete Too Wet. This is probably the easiest concrete mistake to make because properly mixed concrete looks too dry to flow and trowel properly. Don't be fooled. You should be able to form concrete into a fourinch diameter, fourinch tall pile if it's mixed properly.

Get Price -

Crusher, Concrete For Sale

· 2021 Mantovanibenne RP16 Hydraulic rotating concrete pulverizer in top class condition and ready to go to work. Ex rental attachments with 3 months work done. This attachment only weighs 3791lbs so...

Get Price -

How Do Cement Crushers Work

How Do Concrete Crushers Work Single toggle jaw crushers the single toggle crusher is designed for a high capacity throughput due to the elliptical movement of the swing jaw which also assists in the discharge of the crushed material as the .

Get Price -

How to Use Crusher Run for Driveway – YardOwner

Use a utility knife to cut the fabric to size. Now, fill the trench halfway (6inches deep) with large gravel stones to form your base layer. Then, rake the stones for a uniform spread before tamping them down into position with a mechanical roller. Finally, lay your crusher run gravel to form the top layer of your driveway.

Get Price -

A Simple Guide to Concrete Cube Testing

The concrete minimum compressive strength will be specified by the client/designer in a specific format. An example of this is given below: C40/50. The 40 is the compressive requirement of 40 N/mm² of a crushed 100m concrete core and the 50 is a compressive requirement of 50 N/mm² for a crushed concrete cube.

Get Price -

Crushed Concrete Concrete Aggregate 101

· 21AA CRUSHED CONCRETE. 21AA Crushed Concrete is great for drainage which makes it the right solution in wet areas. It's often used as a surface for driveways or parking lots. 21AA Natural. 21AA Natural is a looser material that works for gravel roads or as a base layer underneath asphalt pavement. 22A Crushed Concrete.

Get Price -

Crushing or Crush Concrete Cubes or Cylinder at 28 days

· Concrete elements are designed on the basis of a 28day cube's crushing strength. A 28day cube's strength actually represents the characteristic strength of the concrete. It is mandatory to test the concrete cubes or cylinders at the age of 28 days as per almost all building code requirements. Now, once your 7day test and even your 14day ...

Get Price -

how do small concrete crushers work

Crusher Machine Concrete Crusher, Small Rock Crusher And . ... The machine is in great condition and ready for work. would be suitable for machines . Compact Concrete Crushers

Get Price -

parts of a jaw crusher

Jaw Crusher Parts. Permanscess can provide customer a wide range of high quality mechanical replacement parts for Jaw Crushers. Jaw Crusher Components Parts. Jul 24, 2015 · Jaw Crusher Parts Although the jaws do the work, the real heart of the jaw crusher and its components are the toggle plates, the pitman, and the ply wheel.

Get Price -

how do cement crushers work

how do concrete crushers work icidretin Crusher Wikipedia A crusher is a machine designed to reduce large rocks into smaller rocks, gravel, or rock dust Crushers may be used to reduce the size, or change the form, of waste ...

Get Price -

Hard living: what does concrete do to our bodies?

· M ichael has worked with concrete for 27 years. His job involves "breaking out" walls and floors, mixing concrete, injection work and drilling. ... sand or crushed rock; and cement, which acts ...

Get Price -

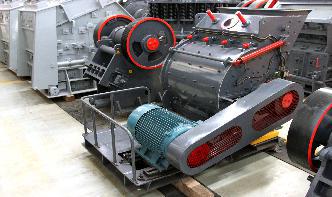

Choosing the right crusher

Choosing the right crusher. A crusher is a machine that uses mechanical energy to break blocks of stone, concrete, or other building materials into smaller blocks of a specific grain size. They are particularly used in the mining industry to reduce the size of ore blocks and facilitate their processing. Crushers are designed to receive blocks ...

Get Price -

How Does a Rock Crusher Work? | Sciencing

· A rock crusher is a device used to crush rocks into smaller pieces, usually for gravel or some other road or building appliion. Most rock crushers have a hopper at the top a container which holds the rock above the crusher and uses gravity to feed it in. Alternately, rock crushers can use a belt drive to continuously transport the rock ...

Get Price