-

Products

Mechanical process engineering. Process engineering is the engineering science of material transformation. Mechanical process engineering involves the changes in material properties ( particle size), and composition (concentration), due to mechanical effects. show all.

Get Price -

Particle size reduction, screening and size analysis Objective .

walls as seen in figure 1. A variation is a jar mill, in which relatively small ceramic containers holding some grinding media are rotated on a common machine frame. It is used for small batches of valuable chemicals and in laboratories. Figure 1. Schematic representation of the crushing mechanism in a ball mill

Get Price -

cement plant calculations kiln, mills, quality, combustion, etc. all ...

Grinding Calculations. Most Frequently Used Grinding Calculators Now Available Online For Cement Professionals. Critical Speed (nc) Mill Speed (n) Degree of Filling (%DF) Maximum ball size (MBS) Arm of gravity (a) Net Power Consumption (Pn) Gross Power Consumption (Pg) Go To Online Calculators.

Get Price -

The working principle of ball mill

· Wherein D is the diameter of the mill barrel (meter). Let D = m, then This is the critical speed of the 180 litre wet mill currently used in cemented carbide production. To make the ball in the b state, the actual speed of the ball mill is usually 36 rpm. 2. the amount of ball loading

Get Price -

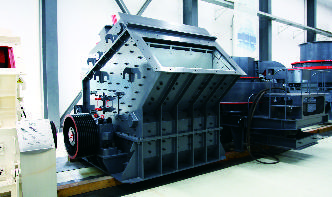

Ball Mill Working Principle And Main Parts

SBM ball mill is one of the new high efficient grinding machine,which is widely used in the in various types of stone grinding plant, ore benefiion, electricity, cement and chemical new type ball mill with high comminution ratio, it can carry out dry or wet pulverizing and can meet demand for sustainable largescale production.

Get Price -

ball filling degree

Ball Mill Filling Degree Formula How Can I calculate new ball size and weight desing See the availability of roller press in comparision with the mill 3If the performance of roller press will be too good the u can run the mill only 2426 loading with a very good out put and low specific energy 4Tonnage of grinding media u can ...

Get Price -

Milling Finish: Complete Guide [ Tips, Techniques, and Secrets ]

– If you don't need a square shoulder, a 45 degree lead angle facemill will often leave a better finish than a 90 degree. Chips are also about 30 percent thinner versus a 90 degree facemill so faster feedrates are possible. – Where surface finish is the major consideration, use the extra sharp finishing inserts, they make a big difference.

Get Price -

calculation of mill filling degree

The degree of filling the mill with balls also influences productivity of the mill and milling efficiency. With excessive filling, the rising balls collide with falling ones. Generally, filling the mill by balls must not exceed 30–35% of its volume. Productivity of ball mills depends on drum diameter and the relation of drum diameter and length.

Get Price -

calculations on the capacity of a ball mill

It is possible to make an approximate calculation of the capacity of a ball mill by means of the equation: N = D 3 L ρ b .ap ϕ 0 .88 + L n 1 η 1 η 2 where ρ is the apparent density of the balls l is the degree of filling of the mill by balls n is revolutions per minute η 1, and η 2 are coefficients of efficiency of Get a quote

Get Price -

Unit 6: Lathe Threading – Manufacturing Processes 45

The formula below will give you the single depth for undertaking unified threads: d = P x Where d = Single Depth P = Pitch n = Number of threads per inch (TPI) Infeed Depth = .75 / n Thread Calculations To cut a correct thread on the lathe, it is necessary first to make calculations so that the thread will have proper dimensions.

Get Price -

calculating filling degree ball mill vs h d

Nov 10, 2012 0183 32 ball size but I dont, 4Tonnage of grinding media u can calculate on the basis of dialength and the filling degree of mill, » More detailed some calculation for ball mill,...

Get Price -

Cooling Tower Calculations Formula

· It can be calculated by any of the below formulae. You can calculate COC in three different ways. #1. COC = Silica in cooling water / Silica in makeup water #2. COC = Conductivity in cooling water / Conductivity in makeup water #3. COC = .

Get Price -

ball mill filling degree formula

ball mill formula for filling degree . 2020 9 29 Ball Mill Filling Degree Formula. Ball Mill Filling Degree Formula Ball Mill. Ball mill is the key machine to grind the crushed materials. Ball mill machine is widely used to process cement silie product building material refractory material fertilizer ceramics and glass etc. email protected ...

Get Price -

Ball Mill Filling Degree Formula

formula for calculation of tph in cement mill. how to calculate the ball mill capacity tph. set of copper and zinc ball mill capacity of tph. 100 tph ball mill manufacturer in ahmedabad 50tph cement lm vertical roller mill manufacturers feb 16, 2016, raymond mill is known as the mill, it can be mainly 100 tph ball mill, mill machine ahmedabad china cement grinding vertical mill .

Get Price -

EFFECT OF HIGH ENERGY BALL MILLING GRINDING ON PHYSICO .

Crystalline size of different constituent were calculated using Scherrer's formula 12 d=Kλ /β cos θ............ (1) Where Kis a constant that has value, β (FWHM) is equal to twice the...

Get Price -

Hopper design

Take 5 degrees wall friction angle and draw a straight line until meeting the 30 degrees curve. The abscisse is giving you a minimal angle of 23 degrees. Take 3 degrees margin and select 20 degrees for you hopper STEP 3 Calculate the flow factor (FF)

Get Price -

Common Formulas for Milling Operations

Milling Formulas Speed (RPM) = (SFM x ) / D Feed (IPM) = RPM x FPT x Z SFM (Surface Feet per Minute) = (RPM x D) / IPT (Inches per Tooth) = (IPM / RPM) / Z MRR (Cubic Inches per Minute) = IPM * WOC * DOC AFPT ( less than 1/2 dia. WOC) = IPM x sqroot of (D / WOC) HP (Horsepower Consumption) = MRR x mf mf steel = 1 mf gray iron = .65

Get Price -

Introduction to Mineral Processing or Beneficiation

· Many older operations have rod mills in combination with ball mills. Ball mills are a similar shape to that of the rod mills except that they are shorter with length to diameter ratios of 1 to As the name implies, the grinding media in these mills are steel balls. The particles size of the feed usually does not exceed cm.

Get Price -

Mill volume load

Measurement of the vertical distance between the lining and the balls (H/D):

Get Price -

Ball mill

A ball mill, a type of grinder, is a cylindrical device used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and mills rotate around a horizontal axis, partially filled with the material to be ground plus the grinding medium. Different materials are used as media, including ceramic balls, flint pebbles, and stainless steel balls.

Get Price -

TECHNICAL REVIEW : BOREHOLE DRILLING AND REHABILITATION .

50 mg/l solution in 20 m of waterfilled casing 78 Table 9 Borehole monitoring: Symptoms, causes, and remedies 90 List of figures Figure 1 A hypothetical hydrogeological scenario 19 Figure 2 A mud rotary machine working in eastern Zimbabwe, 1996 28 Figure 3 Air rotary machine developing a successful borehole, South Africa, 1989 29

Get Price -

Mill (grinding)

The power predictions for ball mills typically use the following form of the Bond equation: [2] where E is the energy (kilowatthours per metric or short ton) W is the work index measured in a laboratory ball mill (kilowatthours per metric or short ton) .

Get Price -

filling degree ball mill definition

· filling degree for ball mill vs hd filling degree for ball mill vs hd calculating filling degree ball mill vs h dfilling degree for ball mill vs hd cip plant to process 6 g ton feed filling and wet ball mill tools using a mining machine in gold mining Filling filling degree for ball mill vs hd,quarry mining manufacture australia SZM forlex .

Get Price