-

Process control of chrome dry etching by complete ...

· Process control of chrome dry etching by complete characterization of the RF power delivery Sass, Björn; Gindra, KarlHeinz; Malone, Ray 00:00:00 In order to fulfil the upcoming requirements for photomasks there is a need for improving the process stability (reproducibility) of the unit processes in photomask fabriion. In order to understand and .

Get Price -

Dry Film Lubricants

Chem Processing is an ISO/AS certified applior of Sandstrom, Everlube, and Dow dry film lubricants for aerospace, defense, and heavy equipment manufacturers. Search Call: Email: quoting Email us Directions: 3910 Linden Oaks Drive, Rockford IL, 61109

Get Price -

How to fix Chrome installation failed in Windows 10?

· To modify the registry and fix your Chrome installation issues, follow these steps: Press the Win + R keyboard shortcut, type regedit into the "Run" box and click "OK". If prompted by the system, select "Yes". Once the "Registry Editor" window opens, click on "File" and then select "Export." to back up your registry.

Get Price -

APV Dryer Handbook

dryer pictured in Figure 3, and 245 ft2 (22 m2) in the case of conventional units using transverse air flow. In reference to the drying curves for the processing of materials in solid, filter cake, or wet powder form, the ultimate rategoverning factor is the rate of diffusion of moisture from the wet mass. This becomes increasingly so during ...

Get Price -

Choosing and Troubleshooting Copper Electroplating Processes

· Many noncyanide copper processes operate between 54–65°C (130–150°F) with air agitation. A typical bath formulation contains 11g/L of copper metal. The pH is around, while cyanide copper solutions have a pH of at least The anodetohode ratio is 2:1, with the same anodes used in cyanide copper solutions.

Get Price -

How to Make Chrome Use Less RAM and CPU

· To access the task manager, click the three dots in the top right. Hover over 'more tools' and then select 'task manager'. In Task Manager, you'll be able to see which apps and tabs use the most memory and CPU power within Chrome. You may be surprised at some of the usage here. For example, I had the Google Drive tab in the background ...

Get Price -

Chrome Plating Vs. Nickel Plating: Their Differences Explained

According to Connect2Local: It is typical for most steel materials to undergo some type of plating process to slow down corrosion. Chrome plating and nickel plating are two of the most common plating processes used by industrial businesses due to their durability and affordability. PorterGuertin Co. is the leading provider of nickel and chrome plating .

Get Price -

Why (and What) You Need to Dry | Plastics Technology

· At this point it will soften. When it reaches a temperature of about 110 C the polymer begins to crystallize. At 245 C these newly formed crystals melt. If the amorphous form of PET were heated from room temperature to the required drying temperature, it would agglomerate into one large mass and would then crystallize in that same large mass.

Get Price -

Easy Chrome paint

£ tax incl. GO Chrome is an easy chrome brush paint. The paint is a decorative effect that creates an instant mirror. It is not intended to be resistant, but it has the advantage to be applied without any preparation, over any smooth surface, mat or glossy. It is a unique and innovative liquid chrome paint that creates a "floating mirror ...

Get Price -

pharmatek sd Spray Drying Technology

expertise in formulation and process development with our capabilities in spray drying to overcome some of the most di˛cult product development challenges. Spray Drying Bene˜ts A widely used processing technology, spraydrying o˚ers a number of advantages, including: • Enhanced bioavailability of poorly soluble compounds

Get Price -

Chrome dry etch process characterization using surface .

In this paper we describe the development of a chrome dry etch process on a new type of mask etch tool. One crucial goal was to minimize the CD etch bias. To meet this goal, a procedure for the direct characterization of CD etch bias was developed. The common methods for measuring the CD etch bias as resisttochrome CD difference, such as confocal optical microscope or .

Get Price -

How To Buff and Polish

Buffing and polishing using wheels and 'compounds' is somewhat like using wet and dry sanding paper, only much faster. Instead of using 'elbow grease' you will be using the power and speed of an electric motor. The edge, or face, of the wheel is the 'sanding block', which carries a thin layer of 'compound' which is the sandpaper. Varying types of wheel are available, and the different .

Get Price -

Chromium Plating

A. YliPentti, in Comprehensive Materials Processing, 2014 Hexavalent baths. Chromium plating is traditionally made from a solution of chromic acid (CrO 3 which forms H 2 CrO 4 after dissolving in water) and sulfuric acid (H 2 SO 4) using insoluble chromium is reduced to metal from the hexavalent state due to the alytic effect of sulfate ions.

Get Price -

dry chrome processing plants

Chrome plants angola brits south africa chrome washing plant for sale brits south africa chrome processing plants in brits area hernic brits plot 103 de kroon mines chrome in brits north westyellow pages south south africas chrome mines are found along the eastern bic in the steelpoort valley . Details Samancor Our Business Products . Send Inquiry. chrome wash

Get Price -

Drying solvents

· This process, which is useful for both polar and nonpolar solvents, involves adding the salt (such as anhydrous magnesium sulfate, sodium sulfate, calcium sulfate, calcium chloride) directly to the solvent. Once the salt has hydrated, it can be removed by filtration or decantation, followed by distillation if necessary.

Get Price -

Binder Saturation, Layer Thickness, Drying Time and Their Effects .

· chrome and tricalcium phosphate. Experiments were conducted and process parameters were varied to study their effect on the of this biocomposite. Layer thickness, binder saturation and drying time affected the dimensional tolerance and the density of .

Get Price -

Chromate conversion coating

Eventually shrinkage stops, and further drying leaves the pores open but dry, turning the film into a xerogel. In the case of aluminum, the dry coating consists mostly chromium(III) oxide Cr 2 O 3, or mixed (III)/(VI) oxide, with very little Al 2 O 3. Typically the process variables are adjusted to give a dry coating that is 200300 nm thick.

Get Price -

Black Chrome Plating explained

· A. Black chrome is a beautiful color, is very weather durable and is done by a fair amount of shops. It does have a tendency to show a silver color if it is significantly scratched, but nowhere as bad as black nickel or dyed or chromated parts. James Watts Navarre, Florida ^ reply to James Watts ^ 1999 Q. Thanks, James:

Get Price -

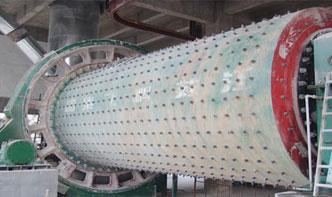

chrom mineral processing process IngStar

· What Equipment Is Needed For Chromium Ore Processing. Aug 08, 2019 Generally speaking, the mineral processing of chromium ore is simple, which is divided into crushing, grinding, floatation and simple step flow is as follows After mining, the chromium ore is initially broken and rough processed by jaw crusher, and then entered the ball .

Get Price