-

Kaolin | Al2H4O9Si2

Kaolin | Al2H4O9Si2 | CID structure, chemical names, physical and chemical properties, classifiion, patents, literature, biological activities, safety/hazards/toxicity information, supplier lists, and more. National Institutes of Health. National Library of Medicine. National Center for Biotechnology Information. PubChem ...

Get Price -

Calcined Kaolin Production Process

Process Flow Diagram For Calcined Kaoli. kaolin clay processing chart flow ylconsulting flow chart of process of calcined coke Diese Seite übersetzen process flow diagram for calcined (in a rotary calciningCompletely calcined kaolin Calcination temperature is ℃ under the electron microscope has been a small amount of mullite crystal the density is .

Get Price -

bauxite mining process flow diagram

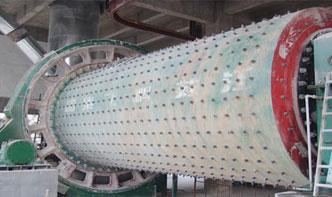

A simplified process flow diagram of the Bayer process used at the Wagerup refinery is presented in Figure 6 411 Bauxite Grinding and Slurry Storage Bauxite is ground to less than 15 mm particle size at the refinery using semiautogenous grinding mills SAG and/or Ball mills to ensure sufficient solidliquid contact during the... Know More

Get Price -

Process Flow Diagram For Calcined Kaolin

Process Flow Diagram For Calcined Kaolin. design of kaolin processing plant. design of a kaolin processing plant haiti a process flow diagram for kaolin mining and dry processing is presented in figure 11251 and figure 11252 design of a kaolin processing

Get Price -

Energy conserving process for calcining clay

The present invention relates generally to the processing of kaolin clay to produce calcined, anhydrous kaolin products in particulate form which are suitable for commercial use. More specifically, the invention relates to a process and apparatus wherein at least a portion of the energy in the hot offgases from the calcirer is recovered and used in the clay processing. .

Get Price -

Laboratory investigation of sulfurous acid leaching of kaolin for ...

A flow diagram for the process sequence is shown in figure l. The major chemical reaction occurring in the calcining step is the dehy dration of kaolin to render the alumina acid soluble, Als03: 2Si05°2Hs0 pi Als5032Si0s =f 2H=0. (1)

Get Price -

Kaolin: processing, properties and appliions

· Appl. Clay Sci., 6:87119. Kaolins are white raw materials, their essential constituent being fine grained white clay, which are amenable for beneficiation that make them ideal for an assortment of industrial appliions. Kaolin deposits can be classified into two types, primary (residual) and secondary (sedimentary).

Get Price -

How to Create a Process Flow Diagram (and Why You Should)

· Process flow diagrams provide a topdown view of how work gets done, making them useful for workflow analysis — the process of analyzing a workflow and improving its efficiency. For example, some processes can't continue without the necessary approvals, in procurement or finance. But getting documents approved is both tedious and timeconsuming. .

Get Price -

Kaolin Concept Study Final

Figure 3 Projected Project Cash Flow ..... 17 Figure 4 Project Returns ..... 18 Figure 5 Project Cash Flow Showing Impact of Grants ..... 18 Figure 6 Brilliant Brumby Tenement Map Showing Prospects and Areas of Prospective Mineralisation ..... 23 Figure 7 Loion of the Brilliant Brumby Prospect, including the Surprise Project..... 28 Figure 8 Initial Hydration of Cement .

Get Price -

KaolinProcessing, Technology, Appliions, Equipment .

Kaolin is a clay mineral more correctly known as kaolinite. It is also called china clay. Kaolin is made up of individual crystals that form units termed "booklets" of stacked sheets. It is a soft, earthy, usually white mineral (dioctahedral phyllosilie clay), produced by the chemical weathering of aluminium silie minerals like feldspar ...

Get Price -

Kaolin Milling And Processing

· A process flow diagram for kaolin mining and dry processing is presented in Figure, and Figure illustrates the wet processing of kaolin. In the dry process, the raw material is crushed to the desired size, dried in rotary dryers, pulverized and airfloated to remove most of the coarse grit. Wet processing of kaolin begins with

Get Price -

flow sheet of calcined kaolin

Get Price. flow sheet of calcined kaolin Kaolin Production Process Chart Stone Crushing Machine. A process flow diagram for kaolin mining and dry processing is presented in Figure, and Figure illustrates the wet processing of kaolin. In the dry process, the raw material is crushed to the desired size. get price

Get Price -

Kaolin WetProcessing

The kaolin is dispersed in water after it is mined. The first step after dispersion is the removal of the coarse grit ( > 44 µ) by settling procedures and vibrating screens. The resultant degritted slurry is fed into centrifuges to separate the kaolin into .

Get Price -

Calcined kaolin for paper

Premium brightness calcined kaolin. Ansilex® 93 calcined kaolin has high brightness with fine particle size. The unique coating morphology (bulk and porosity) generated by Ansilex® 93 enhances aesthetics and printability. It is ideal for improving opacity, brightness, smoothness, ink receptivity, blister resistance, glueability, binder ...

Get Price -

Optimized separation

Iterative process concerning the processed particle size distribution. Information flow diagram to illustrate the internal operations of the electrical model. Representation of the interparticle agglomeration model . Representation of the integration of different models. Case 1 – Hurricane ® appliion example: Simulation of calcined kaolin: a) Particle size distribution (PSD) at the .

Get Price -

Potential of Calcined Recycling Kaolin from Silica Sand Processing .

· Within the first hours, both substituted samples have a similar course of heat flow as the reference (Fig. 7), whereby the samples with calcined clay show a slightly higher heat flow in the dormant period and a slightly faster acceleration period relative to the cement content. In the reference sample, the aluminate reaction is recognizable as a clear shoulder of the silie .

Get Price -

Method for producing high brightness low abrasion calcined kaolin ...

Pursuant to the invention a high brightness, a low abrasion calcined kaolin product is prepared from a cretaceous kaolin crude by the steps of: (a) wet beneficiating the cretaceous crude by subjecting said crude as an aqueous slurry to degritting, classifiion, magnetic separation, and scrub grinding to produce a first slurry;

Get Price -

process flow chart of calcined clay

Process flow diagram for calcined kaolin. Aug 30 Hello we are doing mining equipment manufacturers you see our products please consult Now chatting . Patent US Calcination process for. CALCINATION PROCESS FOR KAOLIN CONTAINING CLAY Filed Nov 1 is a schematic flow sheet of an advantageous embodiment of the practice of my 3 is a graph .

Get Price