-

Tools for the MOBICONE cone crusher | PM | Kleemann

1. Different crushing tools for selection: The tools of MOBICONE cone crushers. Depending on the appliion, a cone crusher from KLEEMANN delivers high tonnages for road subgrade or highquality final products for the concrete or asphalt industry. Depending on requirements, the crushing chamber is equipped with different crushing tools.

Get Price -

GROUT FOR CONCRETE MASONRY – NCMA

Grout Slump. Grout for masonry construction is a high slump material with a flowable consistency to ease placement and facilitate consolidation. Both the Specifiion for Masonry Structures (ref. 7) and ASTM C476 require grout to have a slump between 8 and 11 in. (203 – 279 mm).

Get Price -

Astec Kodiak® Cone Crushers

A unique roller bearing design reduces operating expenses by up to 50 percent while improving production and energy efficiency compared to bushing crushers. The Kodiak ® cone crusher meets coarse and fine crushing appliion requirements and offers onthefly adjustability for easy operation. 7:41.

Get Price -

Volume 1

· (g) Aggregates: T203 Particle distribution of aggregates finer than 75 µm (by washing) Oct12: Current (g) Aggregates: T204 Los Angeles test for coarse aggregates: Oct12: Current (g) Aggregates: T205 Aggregate crushing value: Oct12: Current (g) Aggregates: T208 Water absorption of coarse aggregate: Oct12: Current (g) Aggregates

Get Price -

Density of Aggregate

If the volume is unit then, Bulk Density= Mass. Unit in kg/m 3 or lb/ft 3. In this definition, the volume is that contains both the aggregates and the voids between aggregates particles. The approximate bulk density of aggregate that is commonly used in normalweight concrete is between kg/m3 (75110 lb/ft3) .

Get Price -

METHOD OF TEST FOR UNOBSTRUCTED SLUMP FLOW AND .

slump cone mold to removal of the slump cone mold, without any interruption, and within minutes. 6. If specified in the contract documents: From the time the slump cone mold is lifted, measure the time in seconds it takes for the concrete to reach a diameter of 500 mm (20 in.). This is the T 50 time. 7. When the concrete has stopped flowing ...

Get Price -

Portable Cone Plants

Construction aggregate is typically medium or coarse material that is used in construction appliions. Processing this material may include reducing its size with a crusher, sizing the crushed material with a screen and conveying the material into different stockpiles. Learn More Concrete Recycling

Get Price -

coarse aggregates mm cone crusher dealers

Crusher Is Used For Pebble Gravel Coarse Aggregate Processing. Crusher Is Used For Pebble Gravel Coarse Aggregate Processing Also known as crusher run, DGA dense grade aggregate QP quarry process, and shoulder stone Fine gravel gravel consisting of particles with a diameter of 2 to 8 mm Stone dust fine, crushed, gravel from the final stage of screen separation, such .

Get Price -

Slump Test of Concrete, slump cone for Workability

· Metallic mould in the shape of a frustum of cone having bottom diameter 20 cm (8 in), top diameter 10 cm (4 in) and height 30 cm (12in). Steel tamping rod having 16 mm (5/8 in) diameter, m (2 ft.) long with bullet end. Procedure of Slump test. During Slump test following steps are followed:

Get Price -

Bulk Density: Definition Calculation

· Bulk Density. Bulk density, or dry bulk density, is a property of soils and other masses of particulate material. It's the weight of the particles of the soil divided by the total volume. Thus, it ...

Get Price -

MPS Plant Chosen for Laos Dam Project

· The plant is being fed by blasted sandstone rock with a high abrasion index to produce 0/5, 5/12, 12/25 and 25/50 mm, as dictated by the mix design of the RCC, with any excess being recycled. A reclaiming plant transports aggregates from stock to a cooling plant via two downhill conveyors (one for coarse aggregates with a capacity of 1,800mtph and one for .

Get Price -

Products | McLanahan

McLanahan Corporation offers wet and dry processing products for mining industries, as well as bedding and manure management products for the dairy industry.

Get Price -

Aggregate Designs Corporation New and Used Equipment for the Aggregate .

Aggregate Designs Corporation (ADC) offers a wide array of services for the Aggregate, Asphalt, Concrete and Mining Industries. We provide qualitative new and used products including Asphalt Plants, Jaw Crushers and Cone Crushers. In addition, We offer services which include Construction and Mining Equipment Liquidation, Design and Fabriion ...

Get Price -

Concrete Mix Ratio and How to Mix Concrete | DIY Doctor

2 parts fine aggregate (sand) 4 parts coarse aggregate; If you are using premixed ballast, then: 6 parts pre mixed ballast; 1 part cement; In an ideal world, where everything is delivered dry, a water to cement ratio of approximately should be used. As we have explained above, if requiring 25kg of cement in your mix, then to calulate the ...

Get Price -

High Efficiency Cone Crush Station In Syria

· High Efficiency Cone Crush Station In Syria ... Jan 05 2021 the vibration feeder will feed the stone into the coarse broken evenly by jaw crusher it is the grade crushing fine crushing the broken stone will be transported to the fine broken stone through the belt conveyor it is the grade crushing in the secondary crushing it mainly use the following stone crushers jaw .

Get Price -

Cone Crushers

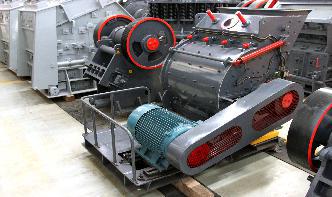

Cone crushers have been used as primary, secondary and tertiary crushers for quite a long time. They are widely employed for crushing hard and abrasive materials in both the aggregate and mining industries. Designed especially for the hardest material types, cone crushers are one of the best choices for crushing river gravel, basalt and granite ...

Get Price -

Cone Crusher

Cone crushers were originally designed and developed by around 1920 and therefore are often described as cone crushers. As the mechanisms of crushing in these crushers are similar to gyratory crushers their designs are similar, but in this case the spindle is supported at the bottom of the gyrating cone instead of being suspended as in larger gyratory crushers.

Get Price -

Coarse

Coarse 10mm Harlaxton Quarry ... 7mm

Get Price -

Tips to maximize crushing efficiency

· Efficiency can be defined by the ratio of a machine's work to the energy supplied to the machine. To apply what this means to your crusher, operations produce the exact sizes in the reduction process that their market demands. In the past, quarries produced a range of singlesize aggregate products – up to 40 mm in size.

Get Price -

CMT "HandsOn" Performance Examinations

Standard Test Method for Materials Finer than 75µm (No. 200) Sieve in Mineral Aggregates by Washing ASTM C123 / C123M14 (AASHTO T 11318) Standard Test Method for Lightweight Particles in Aggregate ASTM C12715 (AASHTO T 8514) Standard Test Method for Relative Density (Specific Gravity) and Absorption of Coarse Aggregate

Get Price -

High Efficiency Cone Crush Station In Syria

· Control Systems On Jaw Stone Crushers Cone Stone Crushers. Control Systems On Jaw Stone Crushers Cone Stone Crushers. Jan 05 2021 the vibration feeder will feed the stone into the coarse broken evenly by jaw crusher it is the grade crushing fine crushing the broken stone will be transported to the fine broken stone through the belt conveyor it is the .

Get Price -

FIELD SAMPLING AND TESTING MANUAL TESTING PROCEDURES .

ND T 191 Density of Soil InPlace by the SandCone Method . ND T 209 Theoretical Maximum Specific Gravity and Density of Hot Mix Asphalt _____ 3/13/2019 Revised Procedures Page 2 of 2 ND T 217 Determination of Moisture in Soils by Means of a Calcium Carbide Gas . Pressure Moisture Tester (Speedy) ND T 224 Correction for Coarse Particles in the Soil Compaction .

Get Price -

what is the bulk density range for mm coarse aggregate

Density Of 20 Mm Coarse Aggregate bcrinfrain. density of coarse aggregate mm swadhikarorgin Bulk density of coarse aggregate (20mm) is approximately 1560kg/m3 The latter mentioned is minimised by gradation using the lesser sizes like 10 mm and 6 mm aggregates to 19 mm aggregates as per the gradation curve to. Read More . Density Of Stone Aggregate .

Get Price -

aggregate syria price uk

aggregate syria price uk. Density Of Cement Sand And Aggregate Cement Density. Cement density measured in kgm kilogramscubic meter density is the ratio of mass to volume so the density of cement in kgm is 1440 in another word 1440 kgm 3 is the density of cement. Aggregate Products. 6a. 381 washed stone. can be round and or crushed. the aggregate .

Get Price