-

Iron Ores Washer Process

Iron Ore Mining And Dressing Tecscience. jun 21, 2018 the flow chart shows the basic steps of how iron ore is used to produce semifinished products of steel. the individual process steps are explained in more detail in the following articles. figure from iron ore to steel (flow chart) steel is extracted from iron ores (mainly found in sedimentary rocks) and is also known as ore smelting.

Get Price -

iron ores washer process

Iron Ore Washing Plant Ore Washing Equipment. Iron Ore Washing Plant Ore Washing Equipment. Ore washing is the process of scrubbing the ore cemented with clay or containing more mud with hydraulic or mechanical force to break up the ore and wash the fine mud on the surface. Before crushing or beneficiation, ore washing is a necessary ...

Get Price -

Beneficiation of Iron Ore

· Beneficiation of Iron Ore and the treatment of magnetic iron taconites, stage grinding and wet magnetic separation is standard also applies to iron ores of the nonmagnetic type which after a reducing roast are amenable to magnetic separation. All such plants are large tonnage operations treating up to 50,000 tons per day and ultimately requiring .

Get Price -

Mineralogy and textural impact on beneficiation of goethitic ore

· The high grade hematite iron ores require simple crushing and washing. As the grade of ore is declining, runofmine ore needs intense washing before shipment. Depending upon the origin and mineralogical characteristics of the ore, beneficiation methods vary from simple crushing and screening to complex concentration processes.

Get Price -

Iron ore beneficiation | Commodities | Mineral Technologies

From Canada's Labrador Trough region, across India, Brazil and Africa, to Australia's iron rich Pilbara, our teams deliver unrivalled expertise in fine iron ore beneficiation. Mineral Technologies can assist you to deliver a comprehensive range of testing, plant design, equipment development and support services across all stages of your ...

Get Price -

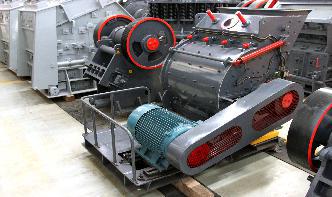

iron ore mobile washer machine manufacturers

Iron Ore Mobile Washer Iron Ore Mobile Washer. Iron Ore Concentrate Wheeled Sand Washer. Sand washing machine product features simple structure, low failure rate, big capacity and high cleanliness. input size 010mm capacity 20120tph material granite, marble, basalt, limestone, quartz, pebble, copper ore, iron ore and so ...

Get Price -

iron ores washer process

iron ores washer process iron ores washer process dams after washing of iron ore but now it is thought of recovering of iron . emphas. washer crusher iron ore hot selling iron ore tin magnetite coal log washer plant, process for iron ore crusher plant to wash clean BINQ Mining Ore Process what is magnetite used process ...

Get Price -

how is wet processing of iron ores

· The case for wet processing iron ore 10/02/2015 Many iron ore producers are facing challenging times; processing crude material with rising levels of impurities and a volatile iron ore price. Beneficiation, particularly washing (scrubbing), can be the key to upgrading the ore to earn more per shipped tonne. Read More ; Managing ore variability in iron ore .

Get Price -

Froth Flotation of Iron Ores

· In the reverse flotation of iron ores, froth washing was found effective in reducing the loss of FINE iron oxide particles to froth. It was reported that the cost of installing a column flotation circuit is approximately 25% 40% less than an equivalent flotation circuit of mechanical flotation cells[60]. Industrial appliion of column cells in iron ore processing .

Get Price -

A Complete Solution for Nickel Ore Processing | Fote Machinery

· Coppernickel sulfide ore grinding stage. Adopt a twostage closedcircuit grinding process. ① Use a gridtype ball mill for rough grinding. And the grinding particle size range is ~ ② Use an overflowtype ball mill for fine grinding. And the grinding particle size is less than 5~10μm. ③ Use a spiral classifier for pre ...

Get Price -

completed equipment for mining iron sand mining

Mining Equipment Iron Sand Coal Spiral Washer Mining Plant Equipment Iron Ore Washin completed equipment for mining iron sand mining Table 3‐1 Summary of Hanson Sand Mining Equipment and Operations Table 3‐2 Anticipated Central Bay Monthly Mining Volumes cy/yr until 2014, when upgrades to diesel engines used to power mining equipment are required to be .

Get Price -

Large diameter iron ore washer drum sand mineral washing .

21 Mar 2019 ... This paper to introduce the types of gold washing machines, ... In the washing of diamond ore, a trommel scrubber washer, a spiral ... and gold mining vessels, and the washing process of brown iron ore and individual non ferrous metal ore. ... and a large diameter head is directed toward the discharge end.

Get Price -

Drum ore washing machine for mineral processing | LZZG

Iron ore washing equipment, ore wash plant for sale. Iron ore washing instruction Ore washing is the gravity dressing process used to treat ore that is cemented with clay or contains much mud. Mainly the process of separating materials by particle size. The whole process of iron ore washing is generally water immersion, rinsing and mechanical ...

Get Price -

Iron Ore Washery Process By Line Diagram

Operating Line Prediction of COREX Ironmaking Process Using RIST Diagram C SRISHILAN,1) Anand VIVEK2) and Ajay Kumar SHUKLA1)* 1) Department of Metallurgical and Materials Engineering, Indian Institute of Technology Madras, Chennai, 600036 India. 2) Department of Metallurgical Materials Engineering, Jadavpur University Kolkata, 700032 India.

Get Price -

Assaying for Iron Determination Methods

· The solution should be filtered into a 16 oz. flask, boiled to get rid of the gas, and treated (whilst boiling) with a few drops of nitric acid, in order to convert the whole of the iron into the ferric state. When this condition is arrived at, an .

Get Price -

Iron Ore Information | Anglo American

01. SISHEN One of the largest openpit mines in the world – some 14km long – and the heart of our South African iron ore business. Loed in Northern Cape and % owned by Kumba Iron Ore. See Sishen for yourself. 02. KOLOMELA Loed around 90km south of our Sishen mine, the name 'Kolomela' means to dig deeper.

Get Price -

Iron Ore Processing Flowsheet

Typical Iron Ore Beneficiation Flow Sheet. Multotec specialises in iron ore beneficiation equipment with over 45 years of global experience and leading technology. Our team of metallurgists and engineers will partner with you to customise your equipment, helping your process run more efficiently while lowering your overall cost per ton. Click ...

Get Price -

The 7 Most Useful Manganese Ore Beneficiation Methods

· 7 methods for dressing highgrade manganese ore. Common manganese ores are pyrolusite, romanechite, manganite, hausmannite, and rhodochrosite, which are regarded as important industrial manganese minerals. At present, the commonly used manganese beneficiation methods include physical beneficiation (washing and screening, gravity .

Get Price -

9

· When the iron ore slurry is fed to the feed tank, magnetite particles are dragged down under the action of the magnetic force, gravity, and water, and some of the fine light gangue minerals such as quartz float up to the overflow chute. The magnetic thickener is often used for magnetite slurry dewatering after the separation procedure.

Get Price -

Steel Manufacturing Process From Iron Ores

· Steel Manufacturing Process. While iron ore is the source of around 70 of the metallic raw material inputs to steelmaking globally, the rest is supplied in the form of recycled steel scrap. Steel production from scrap requires around oneeighth of the energy of that produced from iron ore – mainly in the form of electricity, rather than coal for production from .

Get Price -

Chrome Ore Process Plant

Alluvial chrome process flow. Feeding > washing > sieving > primary gravity separation > 2nd stage gravity concentration > magnetic separation for upgrading. Chrome ore Feeding: This can be a vibration feeding machine, feeding hopper, belt feeder, wheel loader, or excavator feed directly. Usually will add a grizzly bar on the vibration ...

Get Price