-

Lubriing crushing machines in quarries

· By definition, crushers are used to reduce large rocks into smaller rocks or rock dust, depending on the requirement of the operation and material being crushed. The actual crusher can be in the form of a cone, gyratory, impact, jaw, etc. – type machine.

Get Price -

(PDF) SIZE REDUCTION BY CRUSHING METHODS

· Crushing of rock and minerals: ... plate and form the second bump and with the materials'falling dow n,they will be . repeatedly thrown out to the first,second,and third ...

Get Price -

Rock Crushing Plant's Owner Pushes To Open Despite Opposition

· June 15, 2017 / 7:47 PM / CBS DFW FORT WORTH () A concrete and rock crushing plant is trying again to set up along East 1st Street and the Trinity River in Fort Worth. However, after...

Get Price -

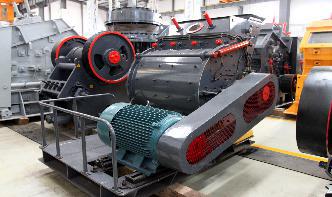

All crusher types for your reduction needs

Crushers are machines used to reduce the size of rocks, stones and ore. They are often utilized in aggregates production, construction material recycling and in mining operations. Outotec offering covers different gyratory crushers, jaw crushers, cone crushers and impact crushers – optimized for any size reduction need. Offering

Get Price -

Crushing Equipment for Sale and Rent | Powerscreening

With new and used rock crushers available, Power Screening can help you get the right rock crusher for your business at the right price. If you are ready to choose a rock crusher, please call (800) or contact us online today. Not sure what kind you want? Read more below or talk to a salesperson who can walk you through the options.

Get Price -

crush form grinding | Mining Quarry Plant

· Original Date: 03/16/1998 Revision Date: 01/18/2007 Best Practice : Form (Crush) Grinding Strite uses form (crush) grinding as . Lee's Grinding Inc. – Crush Form Grinding CAPABILITIES Crush form grinding produces finished parts from hardened blanks in .

Get Price -

Cataclastic rock

Cataclastic rocks form by brittle processes in the upper part of the crust in areas of moderate to high strain, particularly in fault zones. The two main mechanisms involved are microfracturing (breaking the original rock into fragments) and frictional sliding/rolling of the fragments, combined with further fracturing. [6] Cataclastic flow [ edit]

Get Price -

MOBILE ROCK CRUSHING, SCREENING AND CONVEYING .

MOBILE ROCK CRUSHING, SCREENING AND CONVEYING EQUIPMENT PUBLIC AUCTION PPL Group NC License #10214 • Auctioneer, David Muslin, NC License #10208 18% Buyer's Premium Will Apply. LIVE WEBCAST AUCTION: Wednesday, June 29 at 11:00am CT (Online Bidding Only – No Onsite Bidding) INSPECTION: By Appointment Only • ASSET LOCATION: .

Get Price -

Rock Crushing | lathamexcavation

ROCK CRUSHING Rock crushers are an essential part of any excavation company. Lowering job costs, increasing production, speeding up project completion, and recycling existing material are some of the major advantages of crushing rock. Latham Excavation has multiple rock crushers and screening plants. They can be used individually or simultaneously.

Get Price -

How Are Rocks Formed?

· Sedimentary rocks start forming when soil and other materials on the Earth's surface are eroded and finally settle down, forming one layer of sediments. As time passes, more and more materials ...

Get Price -

sedimentary rock | Definition, Formation, Examples,

it can form as the result of deposition of grains from moving bodies of water or wind, from the melting of glacial ice, and from the downslope slumping (sliding) of rock and soil masses in response to gravity, as well as by precipitation of the dissolved products of weathering under the conditions of low temperature and pressure that prevail at .

Get Price -

Samson rock crushing plant | Fallout Wiki | Fandom

The Samson rock crushing plant is a loion in the Mojave Wasteland in 2281, loed directly south of New Vegas Steel and just slightly southwest of the Basincreek Building. This industrial site has been disintegrating for decades, abandoned by prospectors due to the influx of Fiends. The Samson rock crushing plant consists of a series of crusher towers and four buildings .

Get Price -

8 Top Rock Crusher Brands

Extec is another rock crushing brand that's still widely available for resale. Extec was based in the UK with a network of global distributors and was known for its leading design and manufacturing of mobile crushing machines. The company, though, was acquired by in 2007 (along with Fintec), and has since been absorbed under that brand.

Get Price -

Profile

Drilling, Blasting Crushing Plant Hire Haulage About us Drilltech Ltd. was formed in 2007 as a Heavy Civil Engineering and Infrastructure contractor who specialises in Drilling, Blasting and Crushing. Drilltech is a family run business based in Killmallock, Co. Limerick.

Get Price -

Crusher

A jaw or toggle crusher consists of a set of vertical jaws, one jaw is kept stationary and is called a fixed jaw while the other jaw called a swing jaw, moves back and forth relative to it, by a cam or pitman mechanism, acting like a class II lever or a nutcracker. The volume or cavity between the two jaws is called the crushing chamber.

Get Price -

Get more from your rock crusher and screening plants — SRP

Crushing Chambers Having a good understanding of your crushers helps you make smart, informed decisions. Whether you want to build up your knowledge or refresh your memory, this is the place to start. Experience Crushology We've gained a great deal of knowledge and experience through years spent in quarries around the world.

Get Price -

USA

The term rock crushing is used in a broad sense and is intended to designate a plant capable of crushing in addition to rockand stones used in construction work, other material such as ore, for...

Get Price -

jaw crusher process for rock crushing

· Jaw Crusher For Rock Crushing Process. Jaw Crusher For Rock Crushing Process. Sep 02, 2019 The reduction ratio for a jaw crusher is typically 6to1, although it can be as high as 8to1. Jaw crushers can process shot rock and gravel. They can work with a range of stone from softer rock, such as limestone, to harder granite or basalt ...

Get Price